Screw turning device based on infrared intelligent safety control

A technology of safety control and screwing, which is applied in manufacturing tools, metal processing equipment, metal processing, etc., can solve the problems of easily damaged electronic components, small electronic components, and lack of flexibility, so as to achieve high safety and prevent accidents Good effect of outbreak, flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate those skilled in the art to understand, the present invention will be described in further detail below in conjunction with embodiment:

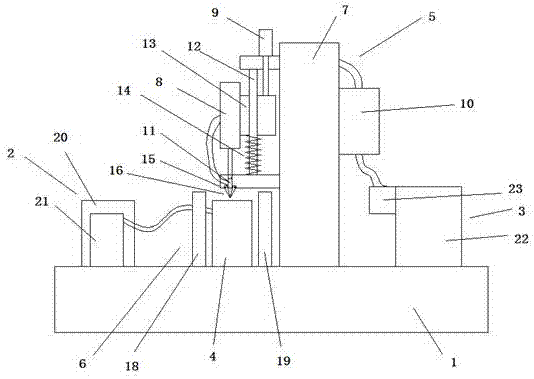

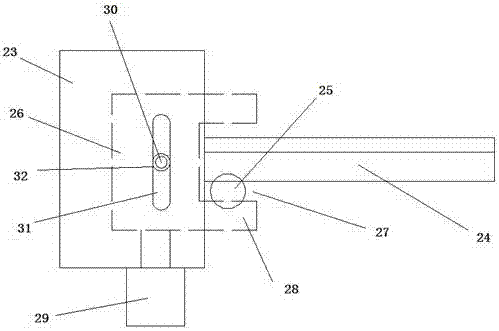

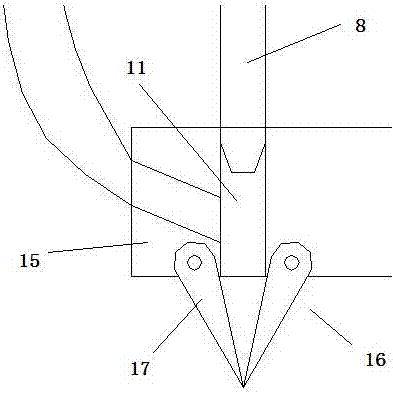

[0024] This embodiment provides a screw-tightening device based on infrared intelligent security control, such as Figure 1-Figure 3 As shown, it includes a frame 1, the frame 1 is provided with a feeding part and an assembly part, the feeding part includes a nut feeding mechanism 2 and a screw feeding mechanism 3, and the assembly part includes a mounting seat 4 and a pair of mounting seats 4 The locking screw mechanism 5 for assembling the workpiece on the nut feeding mechanism, the terminal of the nut feeding mechanism 2 is fed to the mounting seat 4, the terminal of the screw feeding mechanism 3 is fed to the locking screw mechanism 5, and the frame 1 is also provided. The safety brake mechanism 6 that plays a protective role when the accessories are put into the mounting seat.

[0025] The screw locking me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com