Convenient leveling 3D printer

A 3D printer and leveling technology, applied in the 3D field, can solve the problems of difficult frequency modulation and low frequency modulation accuracy, and achieve the effect of simple structure leveling, high leveling precision, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

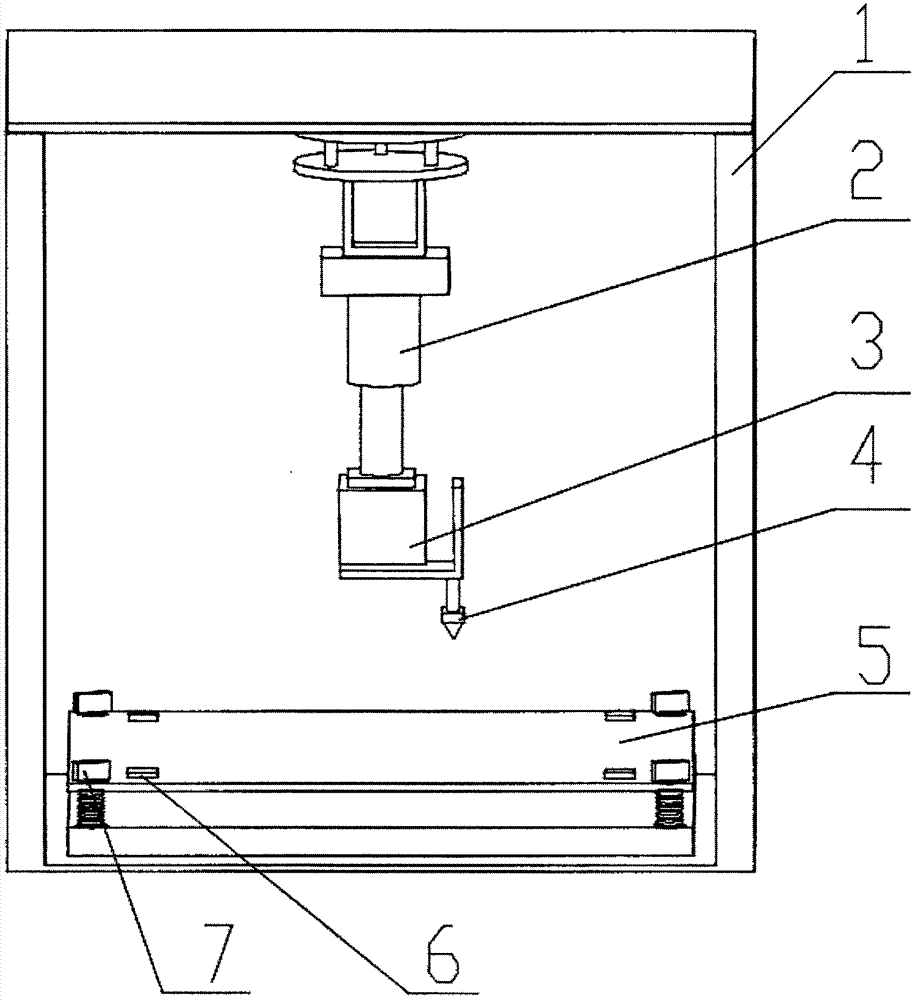

[0011] like figure 1 As shown in the figure, the nozzle 4 and the wire output motor 3 are fixed on the three-axis linkage manipulator 2 by screws; the three-axis linkage manipulator 2 is fixed on the top of the aluminum frame 1 by screws, and the three-axis linkage manipulator 2 can control the nozzle 4 in the The movement in the space corresponds to the position of the hot bed 5, and the 3D printing is completed; a pressure gauge 6 is installed around the upper part of the hot bed 5, and the hot bed 6 is fixed to the bottom of the aluminum frame 1 through the cooperation of the fastening bolt 7 and the spring; Rotating the set bolts 7 can adjust the distance between the hot bed 5 and the bottom of the aluminum frame 1, so that the three-axis linkage manipulator 2 controls the nozzles 4 to contact the pressure gauges 6 installed around the upper part of the hot bed 5 at the same height in the space. , by rotating the fixing bolt 7, the pressure value of the pressure gauge 6 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com