Composite woven fiber rope

A braided fiber and composite technology, applied in the field of cables, can solve the problems of reduced service life of cables, affecting the use of cables, and poor cut resistance of nylon, so as to prevent weight gain, increase service life, improve light resistance and cut resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

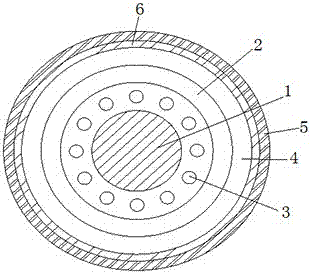

[0017] The technical characteristics of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] The invention relates to a composite braided fiber rope, which includes a rope core (1) and multiple groups of rope strands (2), the rope core (1) is an eight-strand braided rope body, and the rope strands (2) are mutually braided and arranged On the outside of the rope core (1), multiple strands of nylon thick monofilaments (3) are arranged between the rope core (1) and the rope strands (2), and the nylon thick monofilaments (3) are stranded on the rope core ( 1) Outer side, the outer side of the rope strand (2) is provided with a nylon fiber protective cover (4); the outer side of the nylon fiber protective cover (4) is provided with an anti-splitting layer (5), and the anti-splitting layer (5) and the nylon fiber protective cover A waterproof buffer layer (6) is arranged between (4).

[0019] In the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com