Single-cycle grain dryer

A grain dryer and single-cycle technology, applied in non-progressive dryers, dryers, grain drying, etc., can solve the problems of low drying efficiency, low volume ratio of grain dryers, etc., and achieve high heat conversion rate , good practicality and promotion value, ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

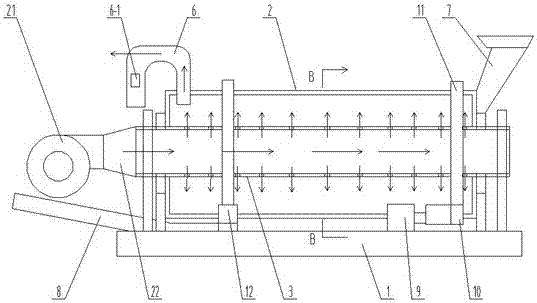

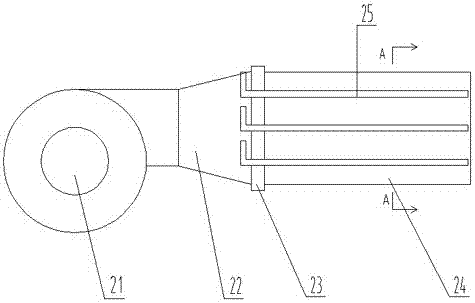

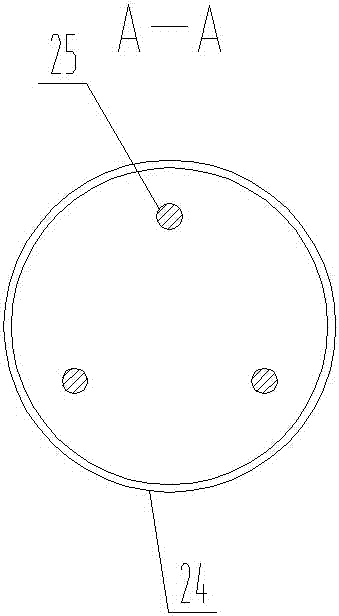

[0016] Such as figure 1 , 2 , 3, 4, and 5, the present invention includes a support 1, an outer drum 2, a lifting board device, a feeding funnel 7, an outer drum rotating device, an inner core tube 3, a conveyor 8 for conveying dry grain, and a delivery Wind module, one end of the inner core tube 3 is provided with a hot air inlet, the cylinder body of the inner core tube 3 is provided with a group of air vents, the outer drum 2 is provided with a grain inlet, a grain outlet and an air outlet, and the outer drum 2 The two ends are movably installed on the support 1 through the bearing seat, the outer drum 2 is set outside the inner core tube 3, the inner wall of the outer drum 2 and the outer wall of the inner core tube 3 form a grain drying channel, and the lifting plate device consists of multiple Groups of L-shaped lifting boards 12, the multiple sets of L-shaped lifting boards 13 are arranged in an annular array on the inner wall of the outer drum 2, the outlet of the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com