Piezoresistive pressure sensor

A pressure sensor, piezoresistive technology, applied in the direction of measuring fluid pressure, fluid pressure measurement by changing the ohmic resistance, and measurement of the property force of the piezoelectric resistance material, which can solve problems such as complex design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

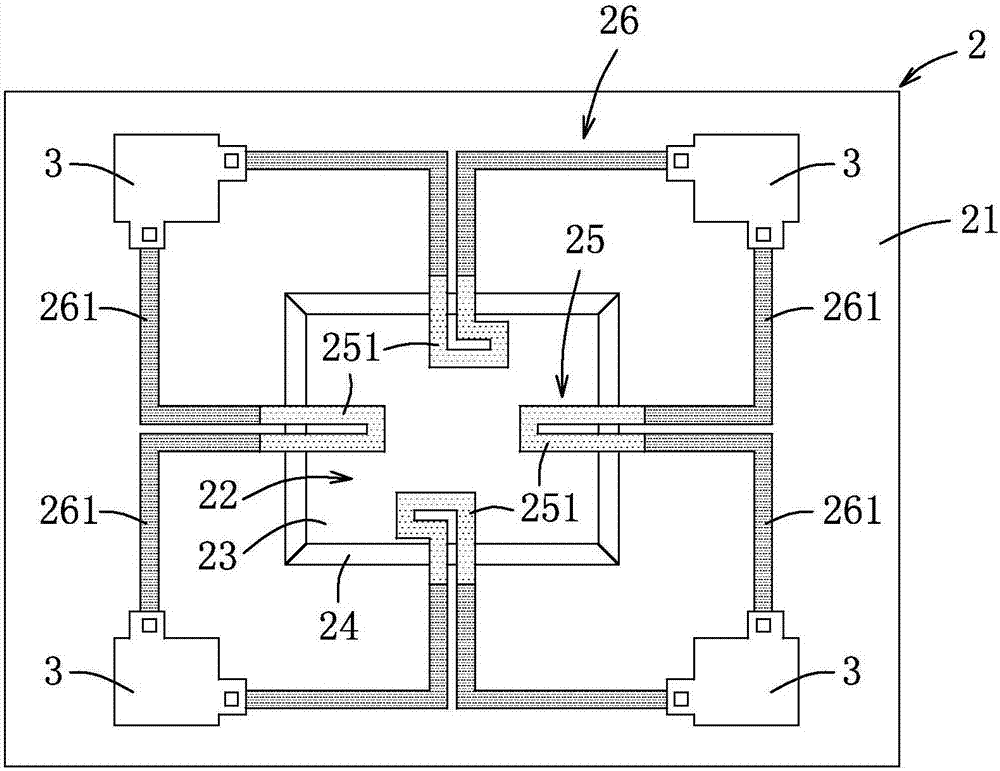

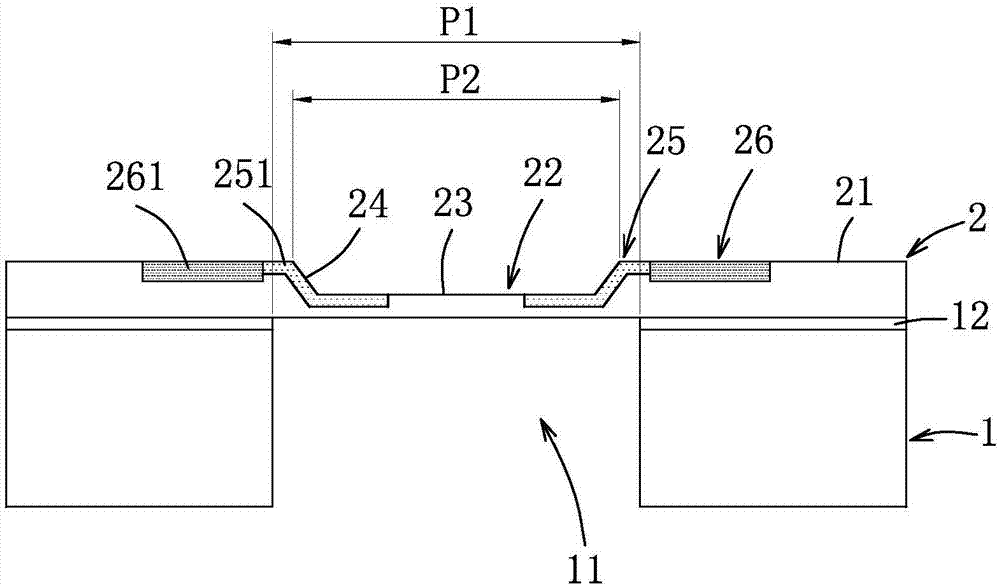

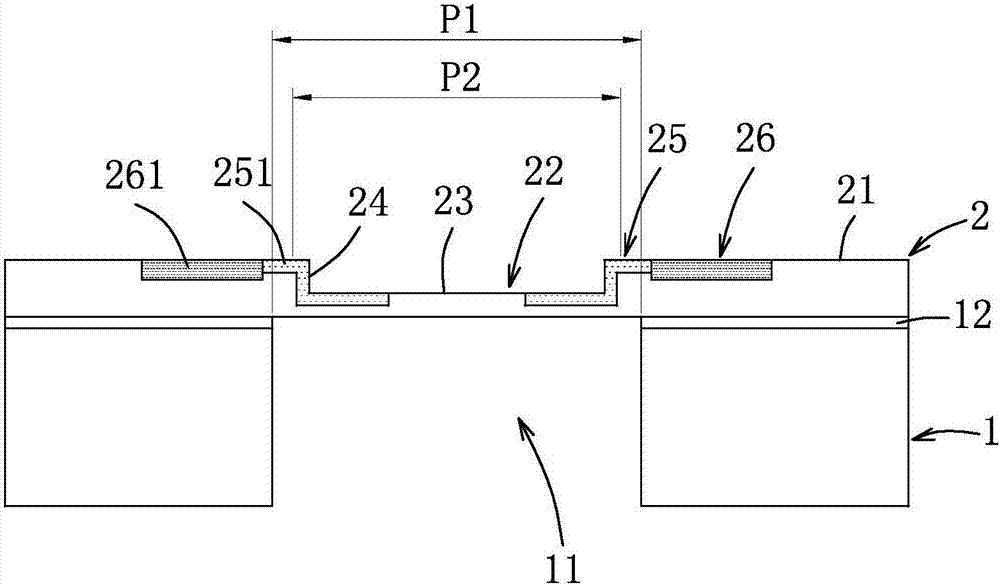

[0026] refer to figure 1 and figure 2 , a first embodiment of the miniature piezoresistive pressure sensor of the present invention includes a substrate 1 and an element structure layer 2 . The substrate 1 forms a vibration space 11 and an insulating layer 12 . The element structure layer 2 is located on the substrate 1 and has an upper surface 21, and a groove 22 corresponding to the position of the vibration space 11 is formed on the upper surface 21, thereby forming a gap between the groove 22 and the Vibrable membrane 23 between vibration spaces 11 . That is to say, the vibration space 11 provides a space where the membrane 23 can vibrate. The groove 22 is defined by the film 23 and a side wall 24 connecting the film 23 and the upper surface 21 . The element structure layer 2 also forms a piezoresistive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com