Silicon dioxide SAB removing method

A silicon dioxide and wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as over-etching, leakage, and difficult to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0024] The silicon dioxide SAB removal method of this embodiment includes the following steps.

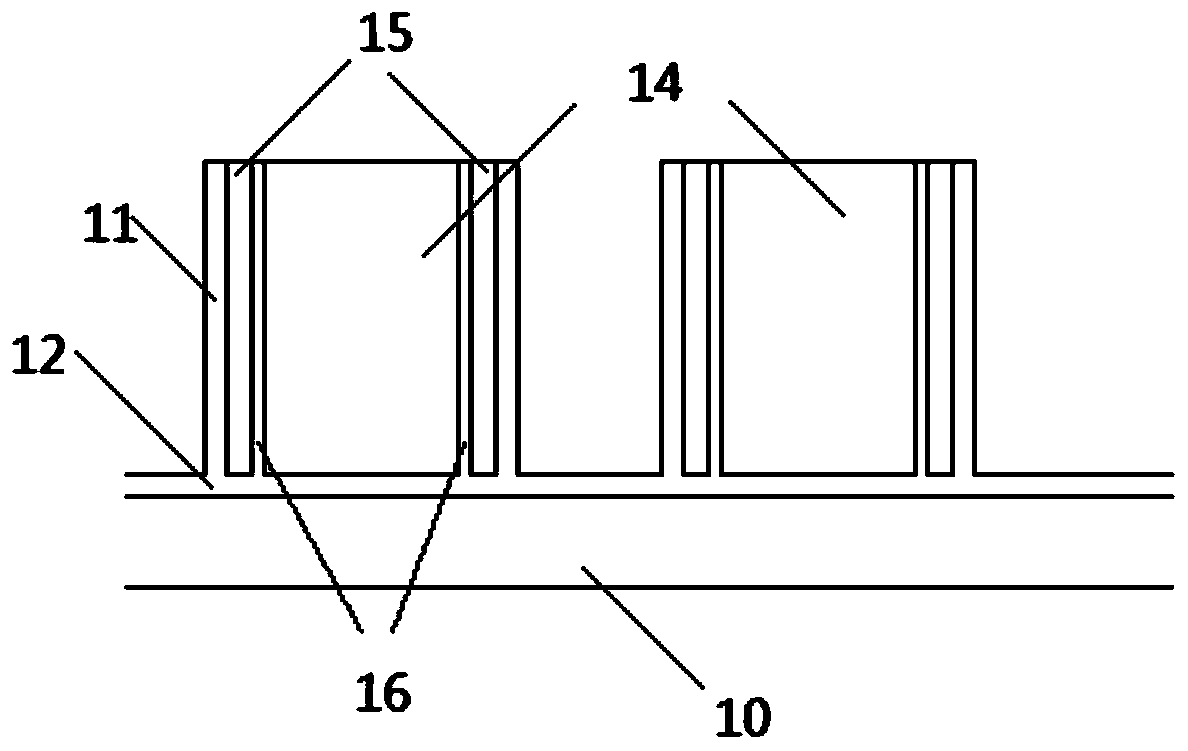

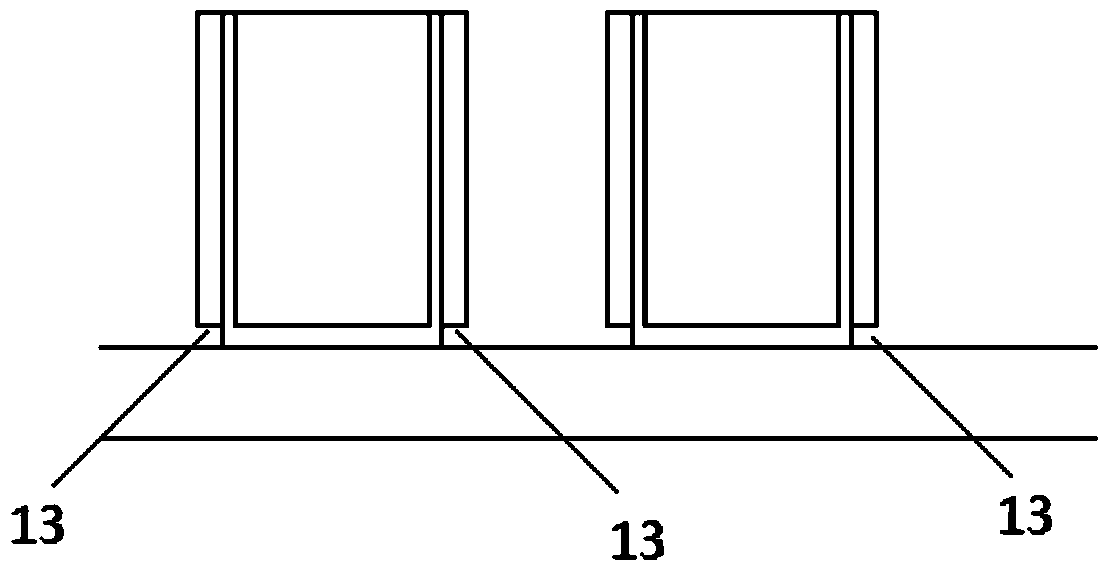

[0025] Step S01 , providing a flash memory chip on which devices are covered by silicon dioxide SAB.

[0026] Wherein, the devices in this step include, but are not limited to, memory cell Cell regions and high-voltage devices, and these devices are all covered by silicon dioxide SAB.

[0027] Step S02, use NH 3 Reacts with HF vapor and the silicon dioxide SAB on the flash chip to generate (NH 4 ) 2 SiF 6 .

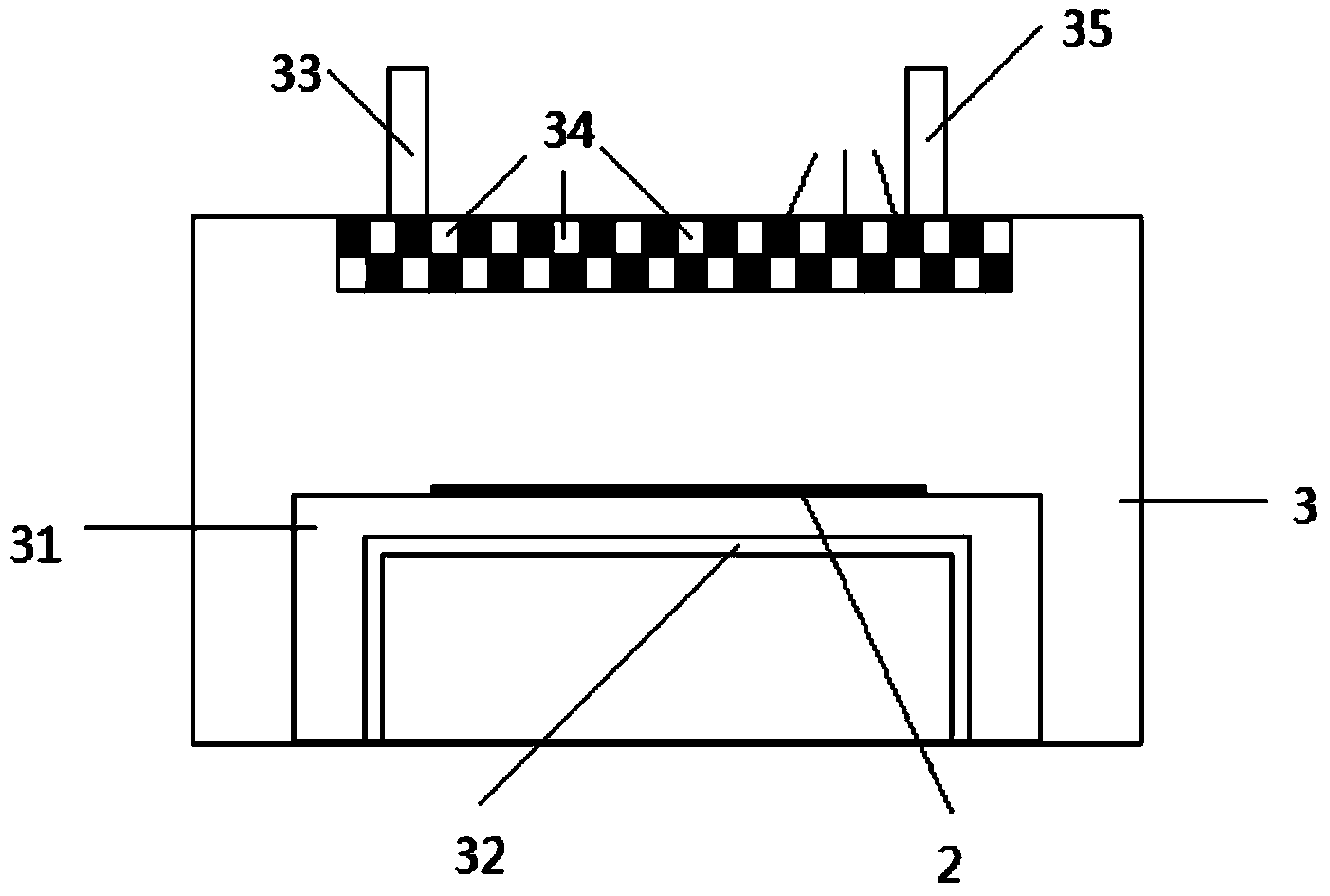

[0028] Wherein, the reaction temperature of this step is room temperature, i.e. 25°C, which is realized by the following settings: figure 2 As shown, the above-mentioned flash memory chip 2 is placed on the first reaction platform 31 in the first reaction chamber 3. The first reaction platform 31 has a built-in constant temperature water pipe 32, which is passed to the first reaction platform by circulating water at 25°C. 31 surface, so that the flash memory chip 2 is k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com