Method for preparing GaN-based inversely-installed thin film structure near-ultraviolet LED

A thin film structure, near-ultraviolet technology, applied in the field of optoelectronics, can solve the problems of divergent luminous angle, insufficient luminous intensity, difficult mass production, etc., and achieve the effects of mild corrosion conditions, small damage, and improved yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

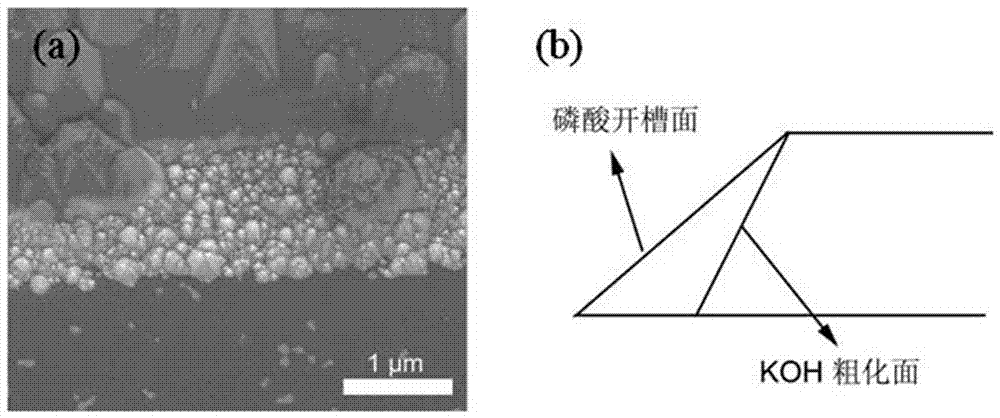

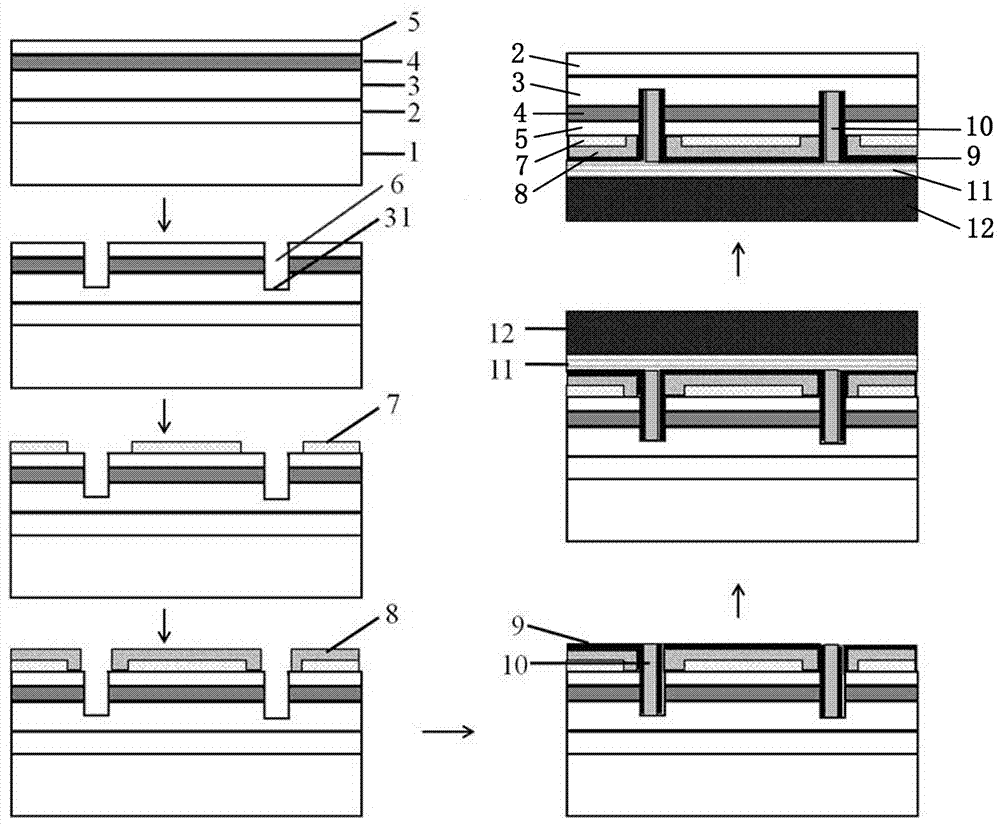

[0034] Such as Figure 2-4 As shown, the embodiment of the present invention provides a method for preparing a GaN-based flip-chip thin-film structure near-ultraviolet LED, including the following steps:

[0035] Step 1) Using a Si substrate as the growth substrate 1, epitaxially growing u-GaN layer 2, n-GaN layer 3, multiple quantum well layer 4 and p-GaN layer 5 on the Si substrate in sequence;

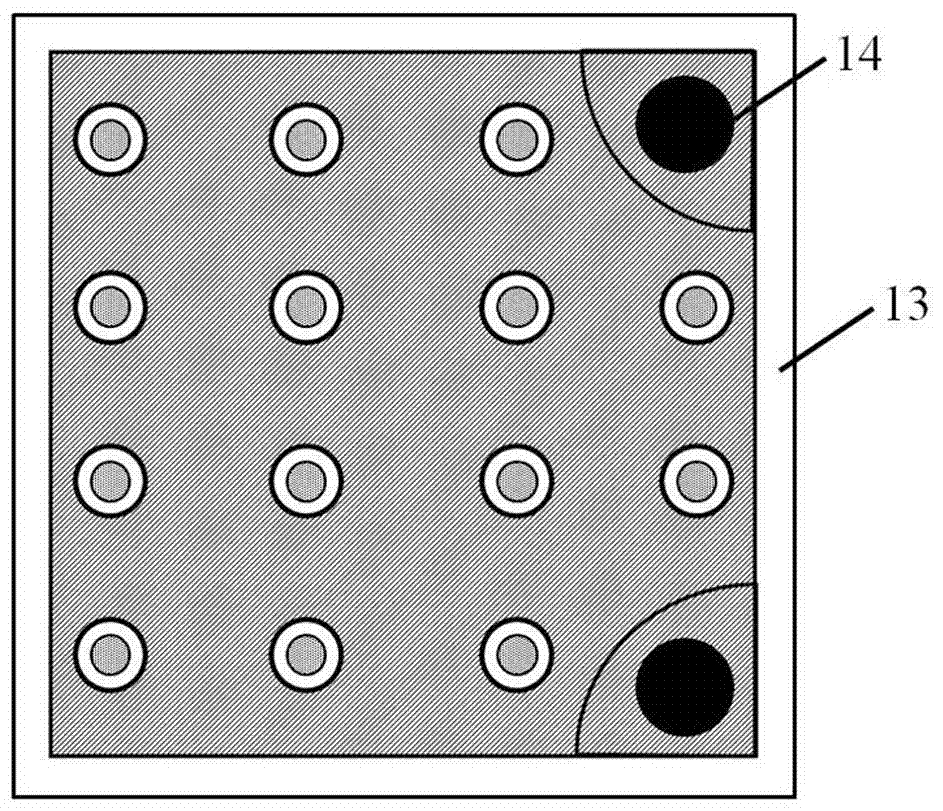

[0036] Step 2) Form a groove 6 that penetrates the p-GaN layer 5 and the multi-quantum well layer 4 and penetrates into the n-GaN layer 3 to a certain depth by photolithography and dry etching in a part of the p-GaN layer 5, exposing the n- GaN surface 31; specifically, the number of etched grooves 6 is 14, that is, the number of exposed n-GaN surfaces 31 is 14;

[0037] Step 3) Fabricate a p-type ohmic contact layer 7 on the surface of the p-GaN layer 5, and the p-type ohmic contact layer also serves as a mirror layer; specifically, the p-type ohmic contact layer 7 is made of ITO,...

Embodiment 2

[0047] This embodiment differs from Embodiment 1 in that:

[0048] Step 1) Using a SiC substrate as a growth substrate 1, epitaxially growing u-GaN layer 2, n-GaN layer 3, multiple quantum well layer 4 and p-GaN layer 5 on the SiC substrate in sequence;

[0049] Step 2) Form a groove 6 that penetrates the p-GaN layer 5 and the multi-quantum well layer 4 and penetrates into the n-GaN layer 3 to a certain depth by photolithography and dry etching in a part of the p-GaN layer 5, exposing the n- GaN surface 31; specifically, the number of etched grooves 6 is one, that is, the number of exposed n-GaN surface 31 is one;

[0050] Step 6) Grow a layer of metal material layer 11 on the insulating layer on the surface of the metal barrier layer 8 and the ohmic contact electrode 10 of n-GaN, and bond the secondary substrate 12 to the metal material layer 11 by means of conductive adhesive bonding superior;

[0051] Step 7) The SiC substrate is removed by grinding combined with ICP etch...

Embodiment 3

[0054] This embodiment differs from Embodiment 1 in that:

[0055] Step 1) Using a sapphire substrate as a growth substrate 1, epitaxially growing u-GaN layer 2, n-GaN layer 3, multiple quantum well layer 4 and p-GaN layer 5 on the sapphire substrate in sequence;

[0056] Step 2) Form a groove 6 that penetrates the p-GaN layer 5 and the multi-quantum well layer 4 and penetrates into the n-GaN layer 3 to a certain depth by photolithography and dry etching in a part of the p-GaN layer 5, exposing the n- GaN surface 31; specifically, the number of etched grooves 6 is 47, that is, the number of exposed n-GaN surfaces 31 is 47;

[0057] Step 6) growing a layer of metal material layer 11 on the insulating layer on the surface of the metal barrier layer 8 and the ohmic contact electrode 10 of n-GaN, and bonding the secondary substrate 12 to the metal material layer 11 by electroplating;

[0058] Step 7) The sapphire substrate is removed by a laser lift-off method to obtain a GaN-bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com