Pressure Sensor

A pressure sensor, pressure technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of reduced sensor accuracy, change in output characteristics, no records, etc., to achieve improved accuracy, improved temperature responsiveness, and reduced deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

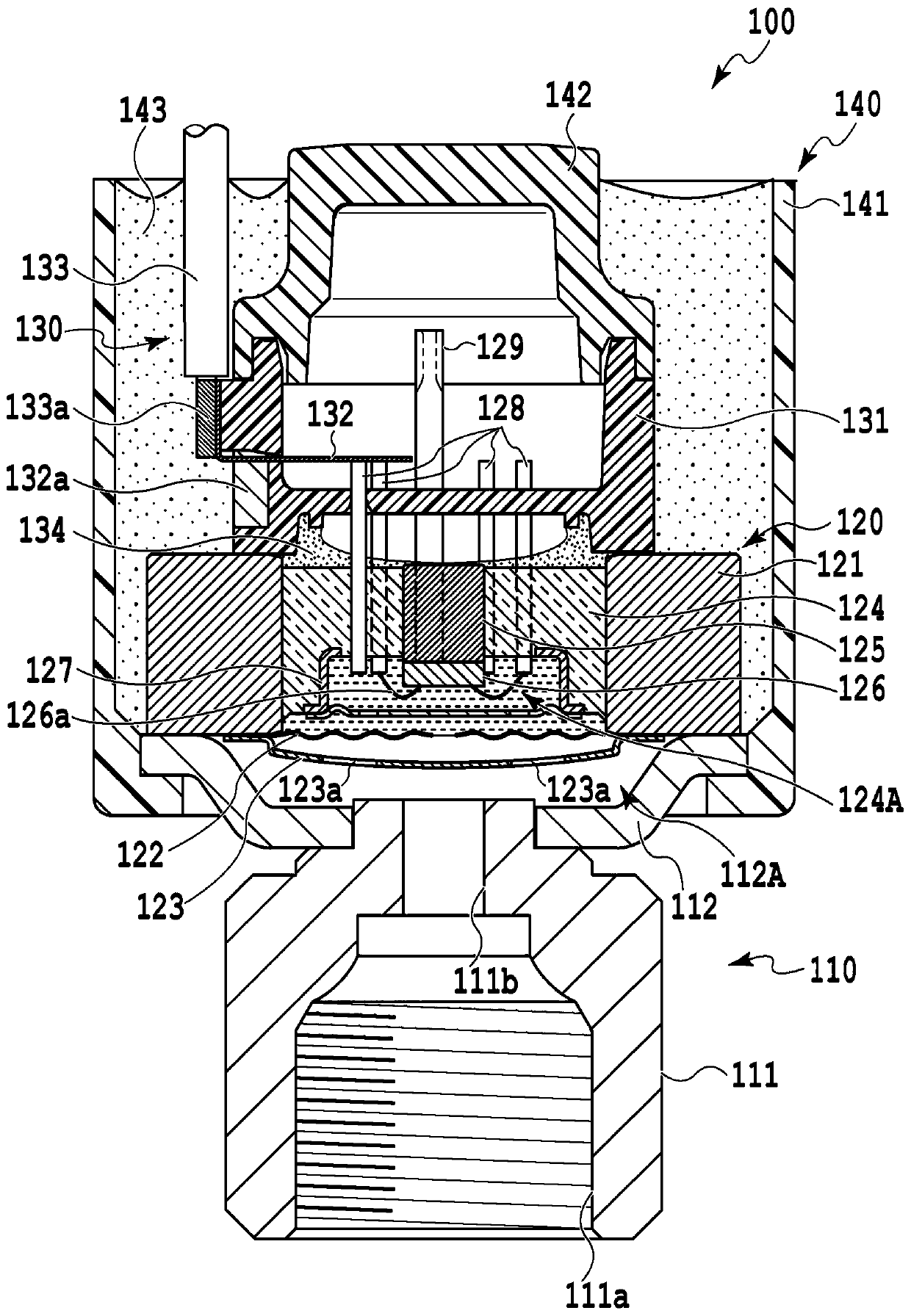

[0037] figure 1 It is a longitudinal sectional view showing a liquid-sealed pressure sensor 100 as an example of the pressure sensor of the present invention.

[0038] figure 1 Among them, the liquid-sealed pressure sensor 100 includes: a fluid introduction part 110 for supplying a fluid to be pressure detected to a pressure chamber 112A described later; a pressure detection part 120 for detecting the pressure of the fluid in the pressure chamber 112A; The signal sending part 130 of the pressure signal detected by the pressure detecting part 120 ; and the outer surface member 140 covering the fluid introducing part 110 , the pressure detecting part 120 and the signal sending part 130 .

[0039] The fluid introduction part 110 includes: a metal joint member 111 connected to a pipe that guides a fluid to be pressure detected; Shaped metal bottom plate 112.

[0040] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com