Experimental device for simulating pseudo-vibration fault of rotating machinery

A technology for rotating machinery and experimental devices, used in measurement devices, vibration testing, and testing of machine/structural components, etc., can solve problems affecting equipment troubleshooting efficiency, accurate diagnosis, and excessive equipment maintenance, and achieve accurate identification and rapidity. processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

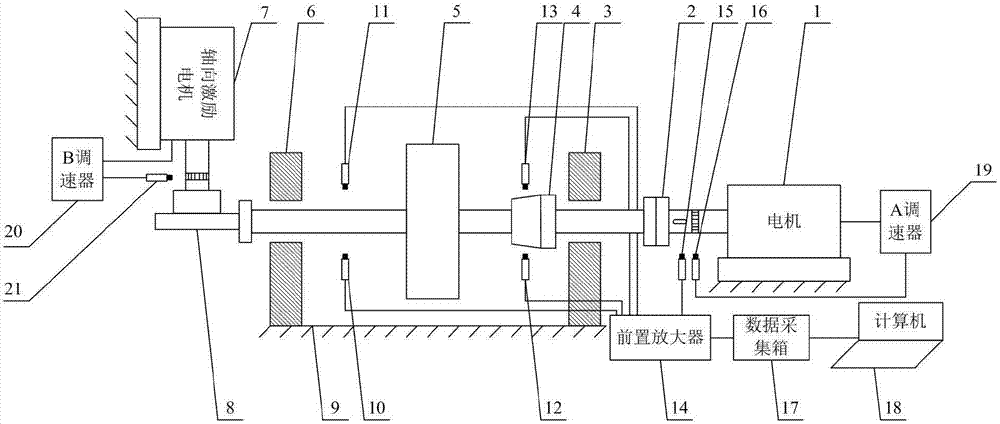

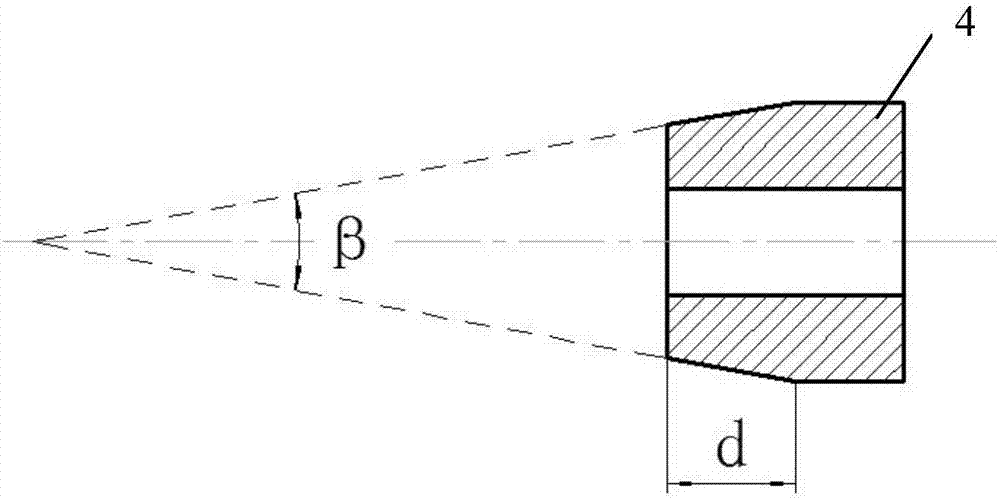

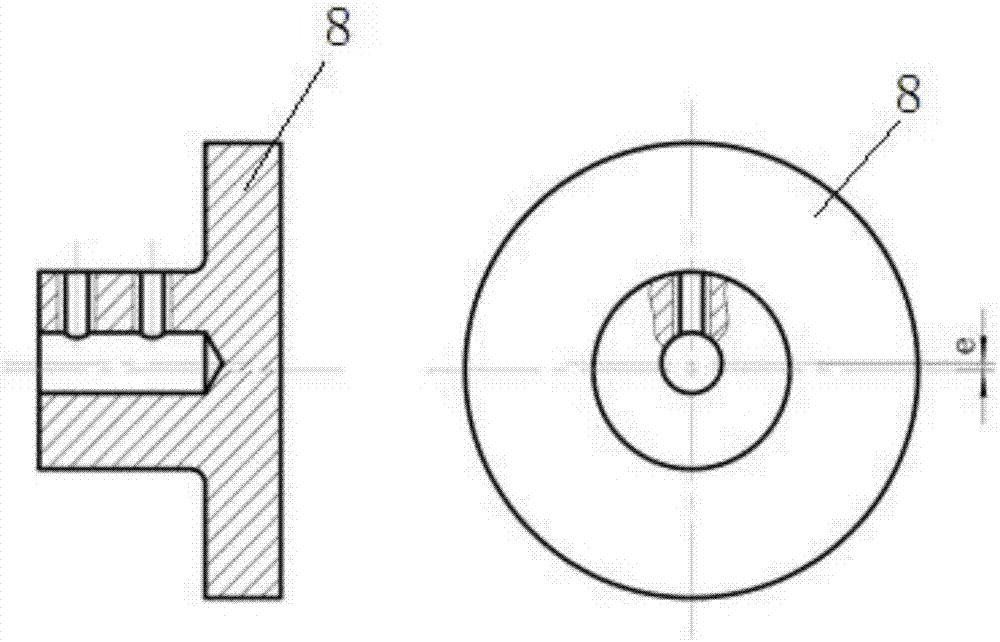

[0019] refer to figure 1 , an experimental device for simulating pseudo-vibration faults of rotating machinery, including a rotor 5, the rotor 5 is supported by a coupling end bearing 3 and a free end bearing 6, the input end of the rotor 5 passes through the flexible coupling 2 and the output shaft of the motor 1 Coaxial connection, a shaft sleeve 4 with surface defects is installed on the rotor 5 close to the bearing 3 at the coupling end, the free side end surface of the rotor 5 keeps in contact with the outer circle of the eccentric wheel 8, and the eccentric wheel 8 is installed on the axial excitation motor 7, the output shaft of the axial excitation motor 7 is perpendicular to the axis of the rotor 5, and the coupling end bearing 3, the free end bearing 6, the motor 1 and the axial excitation motor 7 are all fixed on the base 9 superior;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com