Airborne Ultrasonic Test System for Test Objects

A technology for test objects and test systems, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc. Issues such as ringing effects are not displayed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

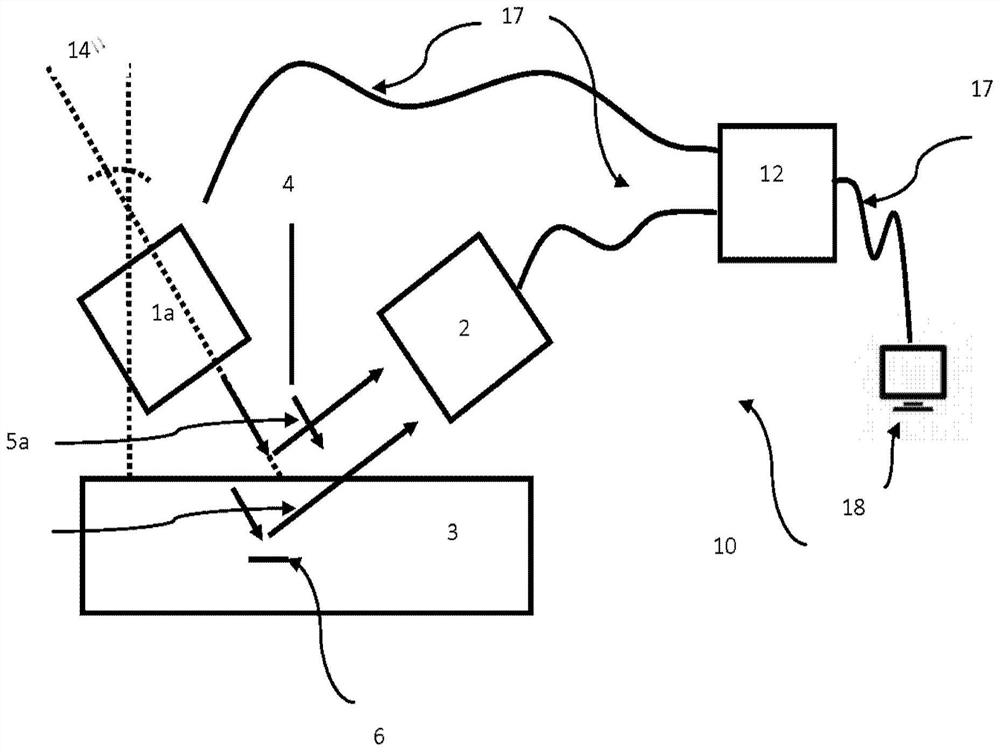

[0064] figure 1 Shown in is a typical inventive device. The onboard ultrasonic waves 5 are emitted from the thermoacoustic generator 1 a into the air or into another sound propagation medium (eg a specific gas 10 that may be present in the test environment). Such specific gases may include, for example, nitrogen or carbon dioxide or gas mixtures, for example, thorlabs Inc ( https: / / www.thorlabs.de ), which is favored due to the fact that the test object 3 will not be exposed to oxygen, which is also enhanced by the fact that the pressure-related change in the refractive index depends on the medium Sensitivity of diaphragmless and non-resonant optical microphones is preferred. The sound propagation medium can also be any liquid (eg, oil, water, blood or others); however, the efficiency of the thermoacoustic generator is more favorable when used in gas. As a result, the sound propagation medium will generally be ordinary ambient air. Sound waves are incident on the test ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com