Support

A front pillar and rear pillar technology, which is applied to the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of poor stability, poor safety, and small external force of the support, and achieve safe and reliable use and low manufacturing cost. , the effect of good support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

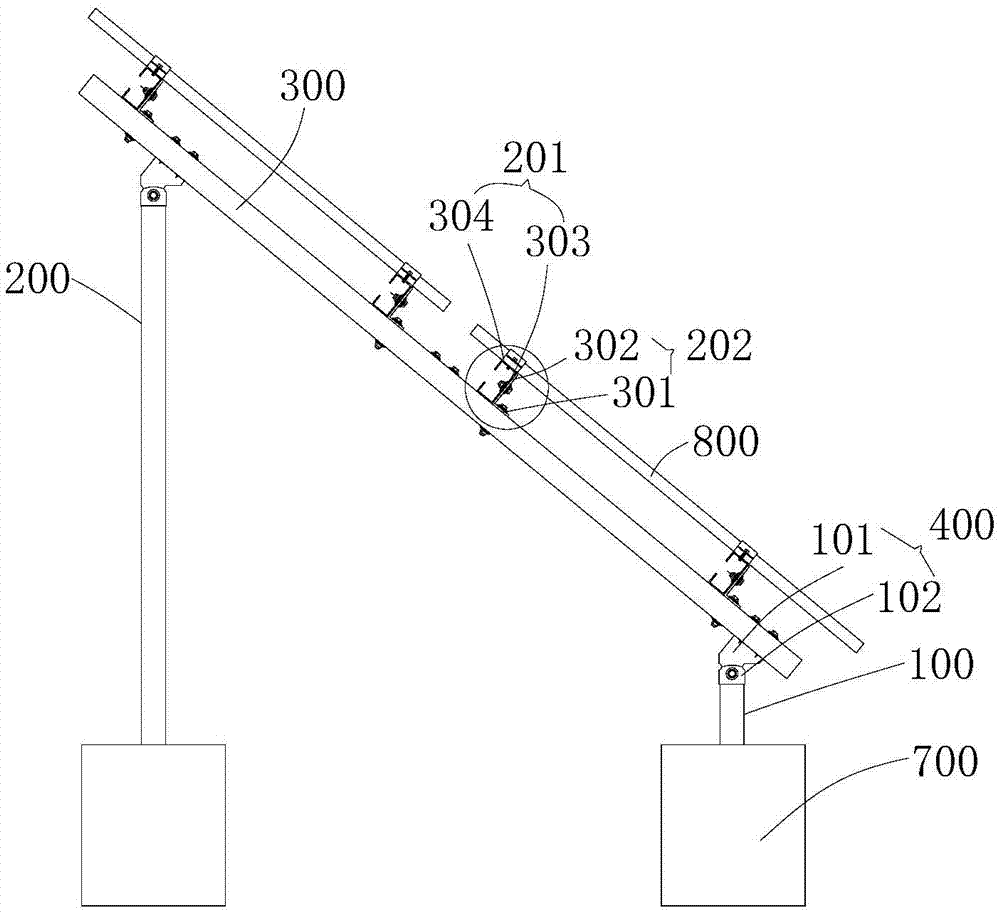

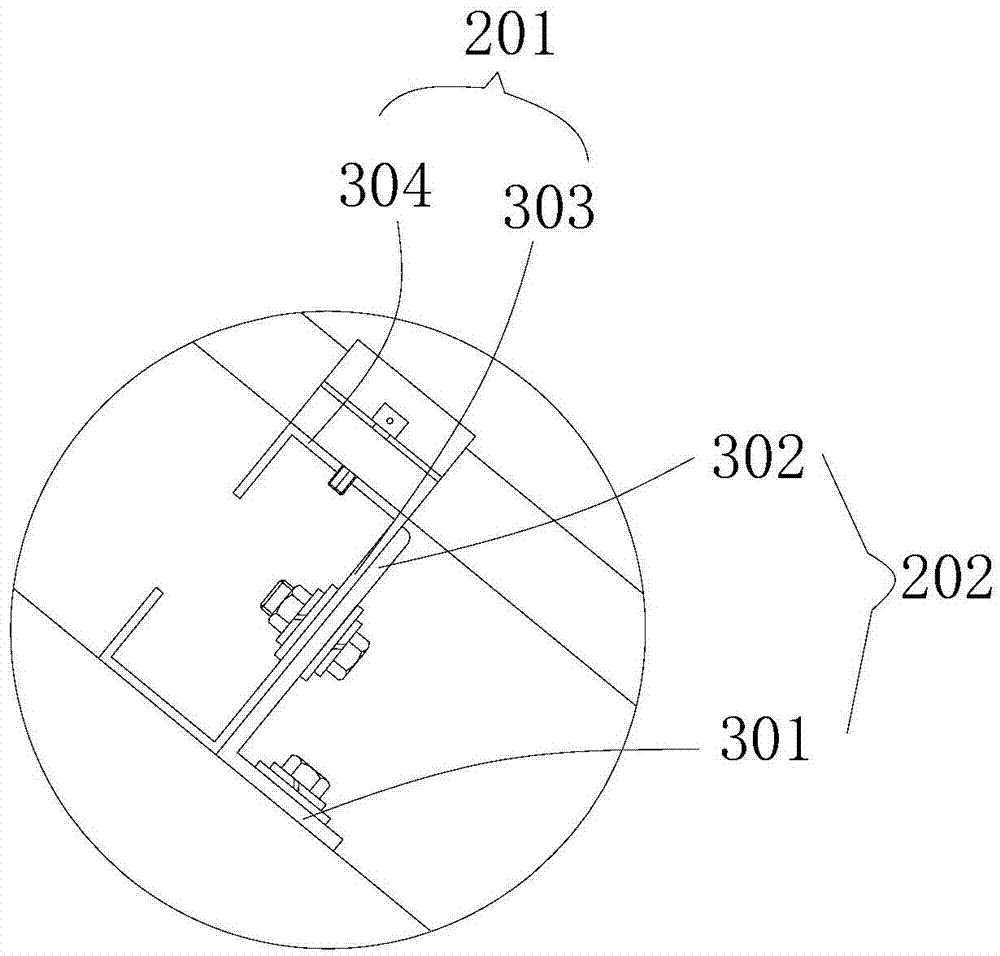

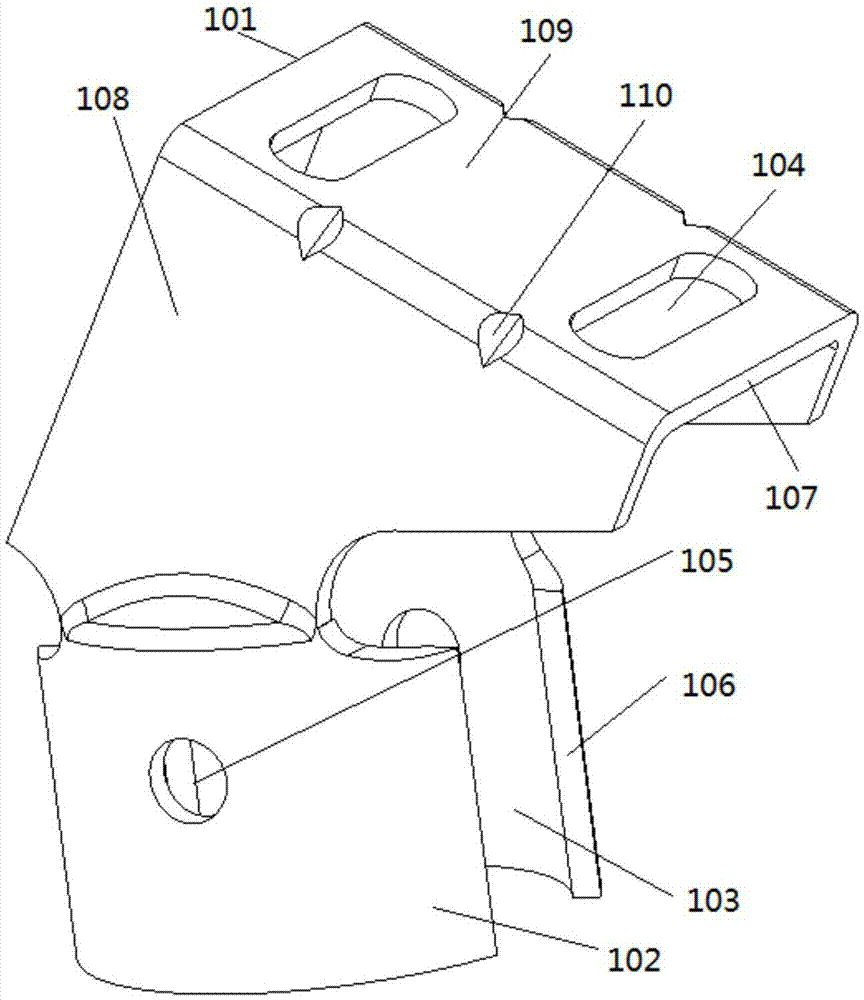

[0041] see Figure 1-3 , the embodiment of the present invention provides a bracket for installing a photovoltaic module 800, including at least one support unit, the support unit includes a front pillar 100, a rear pillar 200, a slanting beam 300, and a plurality of first transfer connectors 400 , the supporting unit is used as the basic unit supporting the photovoltaic module 800, the number of supporting units is set as required, and determined according to the area of the photovoltaic module 800, in order to improve the stability of the photovoltaic module 800 after installation, there are multiple supporting units, multiple The supporting units are arranged at intervals along the length direction of the photovoltaic module 800. Preferably, there are two supporting units. The two supporting units are close to the two ends of the length direction of the photovoltaic module 800. , the photovoltaic module 800 is evenly stressed, and is not easy to fall over.

[0042] Durin...

Embodiment 2

[0054] see Figure 4 , this embodiment also provides a bracket, the transfer connector provided in this embodiment is a further improvement on the basis of the technical solution in the first embodiment, and the disclosed technical solution in the first embodiment is also applicable to this embodiment, In order to avoid repetitive and cumbersome descriptions, the technical solutions already described in Embodiment 1 will not be described again.

[0055] The bracket also includes an oblique strut 500 and a second transfer connector 600, the oblique strut 500 is located between the front strut 100 and the rear strut 200, one end of the oblique strut 500 is hinged to the rear strut 200, the other end of the slanting strut 500 is hinged to the slanting beam 300 through the second adapter. The slanting beam 300 is supported between the front pillar 100 and the rear pillar 200, and can withstand a certain gravity, which further strengthens the firmness of the overall structure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com