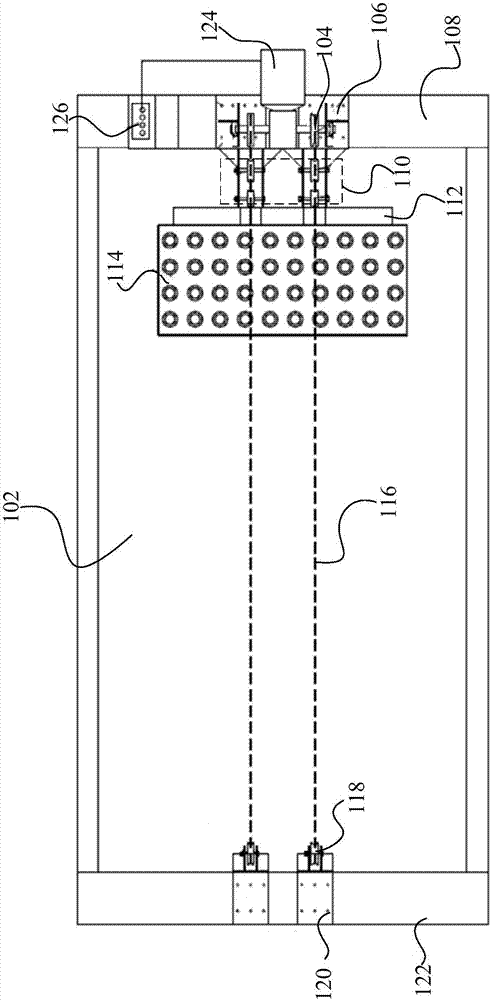

Automatic conveying system

A technology of automatic conveying and driving wheel, which is applied in the fields of botany equipment and methods, soilless cultivation, cultivation, etc., can solve the problems of waste of manpower, chaotic arrangement of cultivation carriers, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

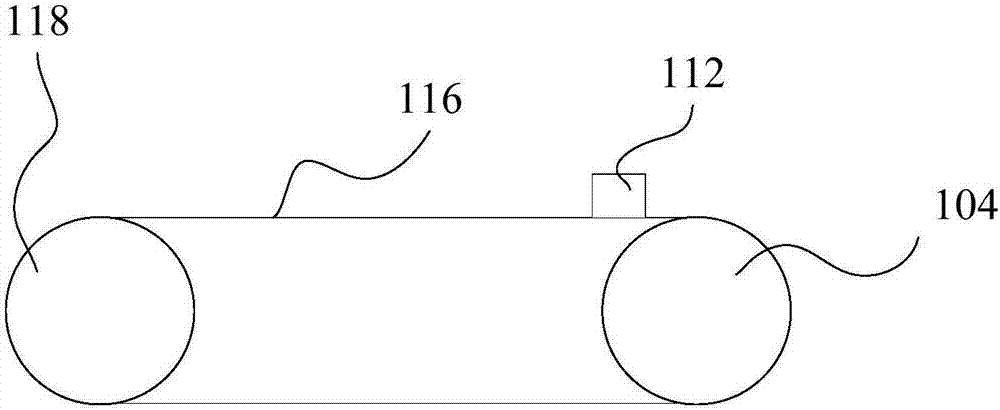

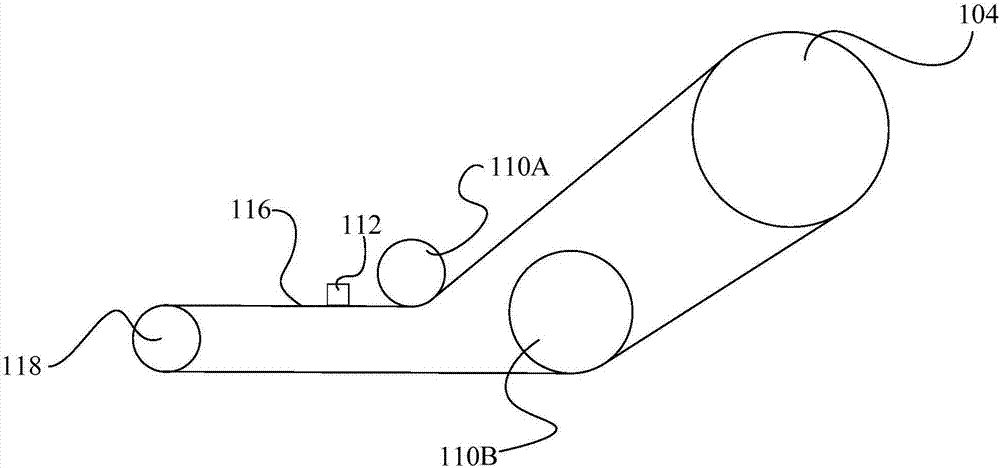

Method used

Image

Examples

specific Embodiment

[0080] Such as Figure 4 As shown, there are multiple cultivation carriers between A and A1. When the plants on the cultivation carrier A in the harvest area M grow to the harvest stage, the cultivation carrier A is harvested from the harvest area M. After the position of the cultivation carrier A is vacated , the drive motor 124 drives the push rod to push the cultivation carrier A1, thereby pushing the cultivation carrier B to the harvest area M. Afterwards, the driving motor 124 is reversed to make the push rod return to the upper seedling position, and the cultivation carrier A2 is put into the upper seedling area N. Harvest the cultivation carrier B. After the cultivation carrier B is vacated, the drive motor 124 drives the push rod to push the cultivation carrier A2, thereby pushing the cultivation carrier C to the harvest area M. Such a cycle realizes the automatic push of the cultivation carrier from the seedling to the harvest.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com