Large-egg-turning-angle hatching machine

A technology of turning eggs and angles, which is applied in the field of poultry egg hatching. It can solve the problems of low efficiency of air circulation system, inability to turn eggs at large angles, leeward wind and narrow air path, etc., so as to improve work efficiency, increase hatching rate, and promote embryonic development. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

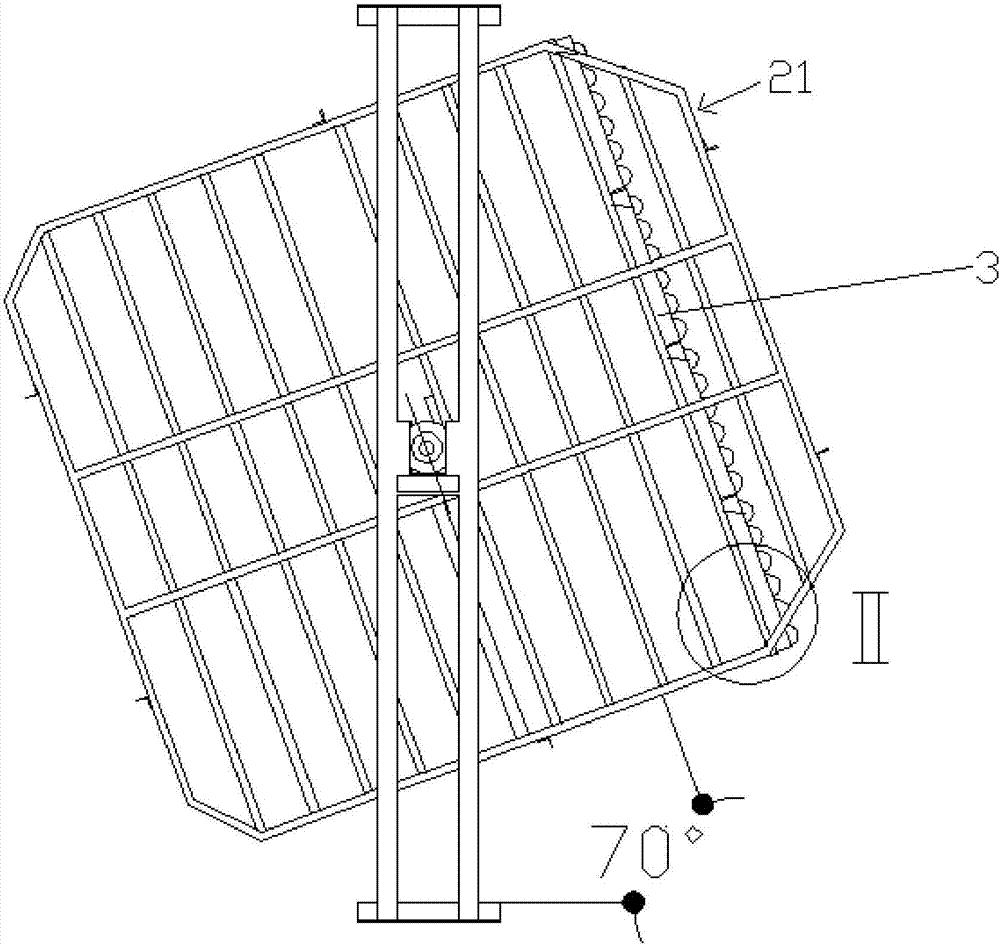

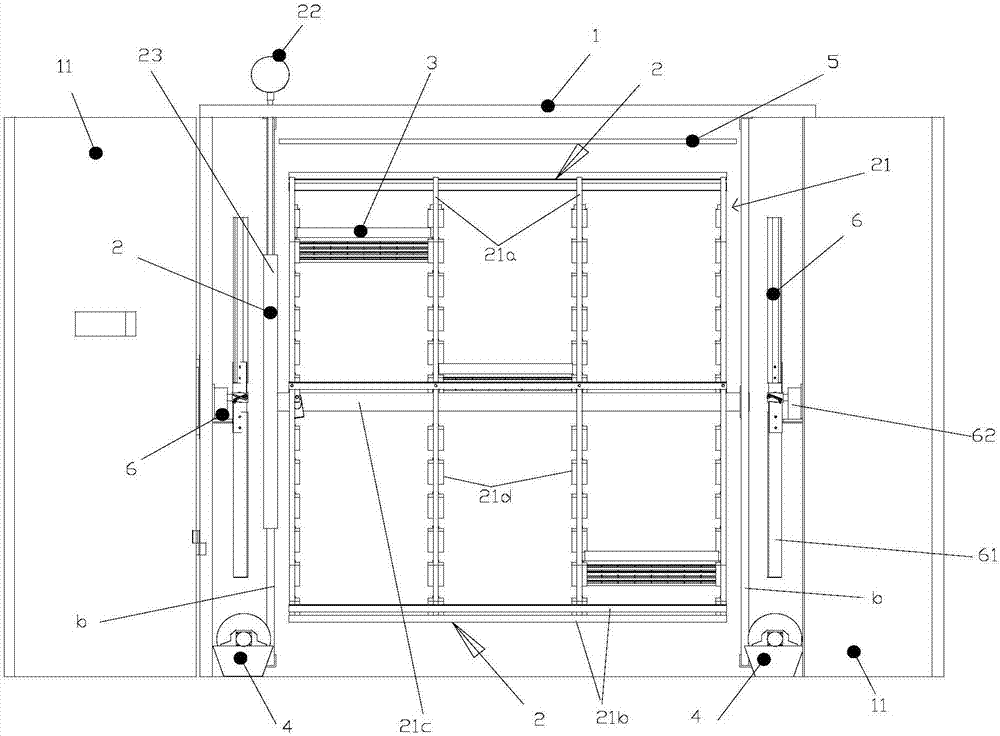

[0042] Such as figure 1 , 2 , 3, the incubator of embodiment one includes incubator 1, octagonal automatic egg turning device 2, egg tray 3 ( figure 1 Middle 3 refers to an egg tray, figure 1 The middle egg rack is in a state inclined to the inboard of the incubator 1, so figure 1 The angle of view of the middle egg tray 3 is equivalent to being inclined upward), the humidity adjustment system 4, the temperature adjustment system (not shown), the water spray system 5, the air circulation system 6 and the master controller (not shown).

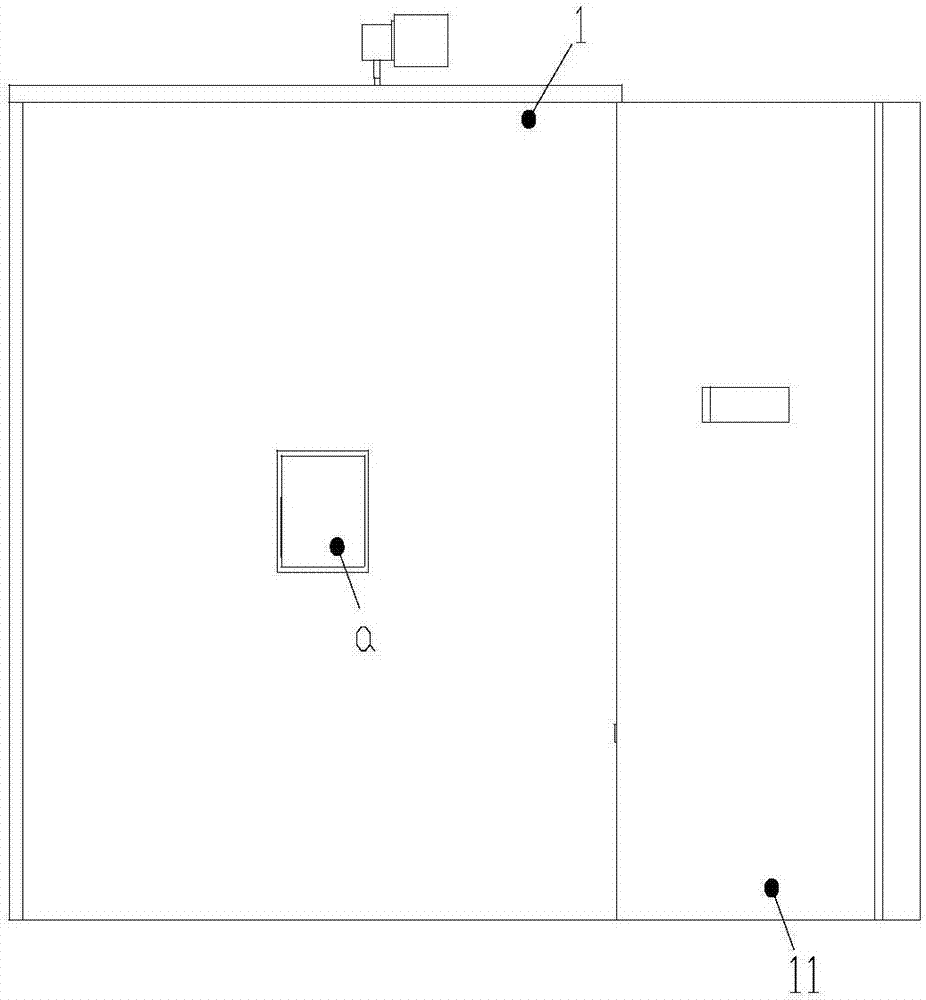

[0043] The incubator 1 front is provided with chamber door 11, and this chamber door 11 is a side-by-side door, and damper is all arranged in the middle part of both sidewalls, and several air outlets are also arranged on the top, and exhaust fan (not drawn) is installed in the air outlet place. A one-way air valve is installed at the air door, and the air valve adopts an air door cover a.

[0044] Such as Figure 5 As shown, the damper co...

Embodiment 2

[0066] Embodiment 2 is different from Embodiment 1 in that two octagonal automatic egg-turning devices are arranged horizontally side by side in the incubator of the incubator of embodiment 2, and the egg rack of the octagonal automatic egg-turning device is composed of three oppositely arranged The octagonal iron frame is connected. Embodiment 2 The door on the front of the incubator of the incubator is two single doors arranged at intervals, and the control box of the incubator is installed on the box wall between the two single doors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com