Full-automatic 13-tank glass cleaning and immersion plating production line

A glass cleaning and production line technology, applied in the direction of cleaning flexible objects, cleaning methods and utensils, cleaning methods using liquids, etc. The effect of hiding dirt and precise location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

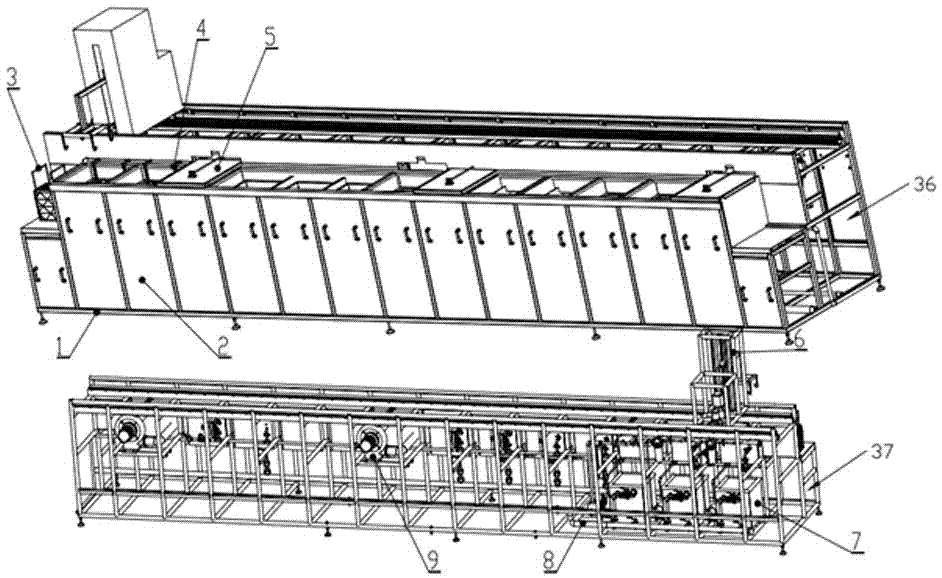

[0023] see Figure 1-3 , a fully automatic 13-slot glass cleaning and immersion plating production line, including a processing part 36 and an assembly part 37; , the top of the workpiece 36 is fixedly connected to the hanging basket 3, and the outside of the workpiece 36 is provided with an outer sealing plate 2, and the outer sealing plate 2 is fixedly connected to the main frame 1 by welding.

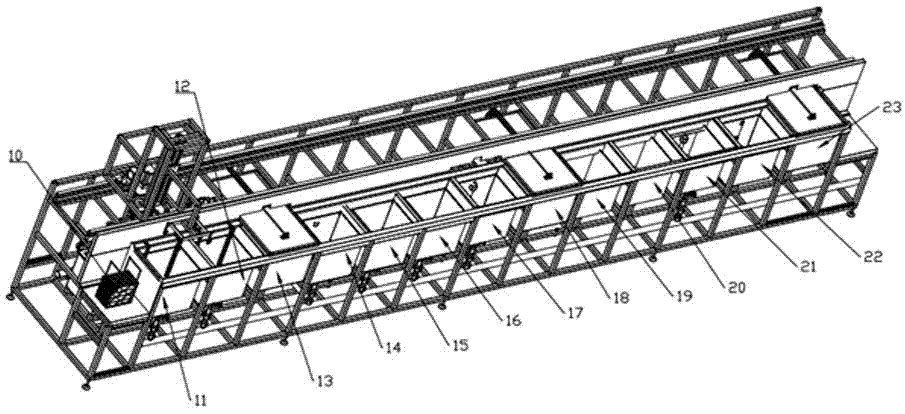

[0024] The workpiece 36 is sequentially provided with a first groove 11, a second groove 12, a third groove 13, a fourth groove 14, a fifth groove 15, a sixth groove 16, a seventh groove 17, an eighth groove 18, a The ninth groove 19 , the tenth groove 29 , the eleventh groove 21 , the twelfth groove 22 and the thirteenth groove 23 .

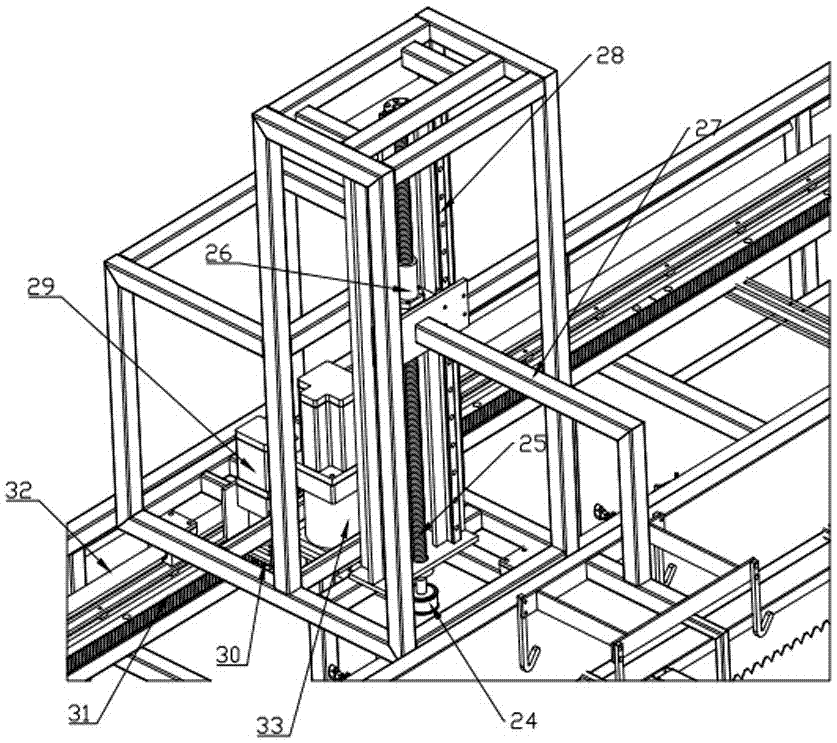

[0025] The manipulator 6 is fixedly connected to the top of the assembly part 37, and the liquid storage tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com