Splashing prevention plate perforating device

A punching device and anti-splash technology, which is applied in woodworking safety devices, wood processing equipment, fixed drilling machines, etc., can solve problems such as operator injury and waste debris splashing, and achieve the effect of improving service life and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

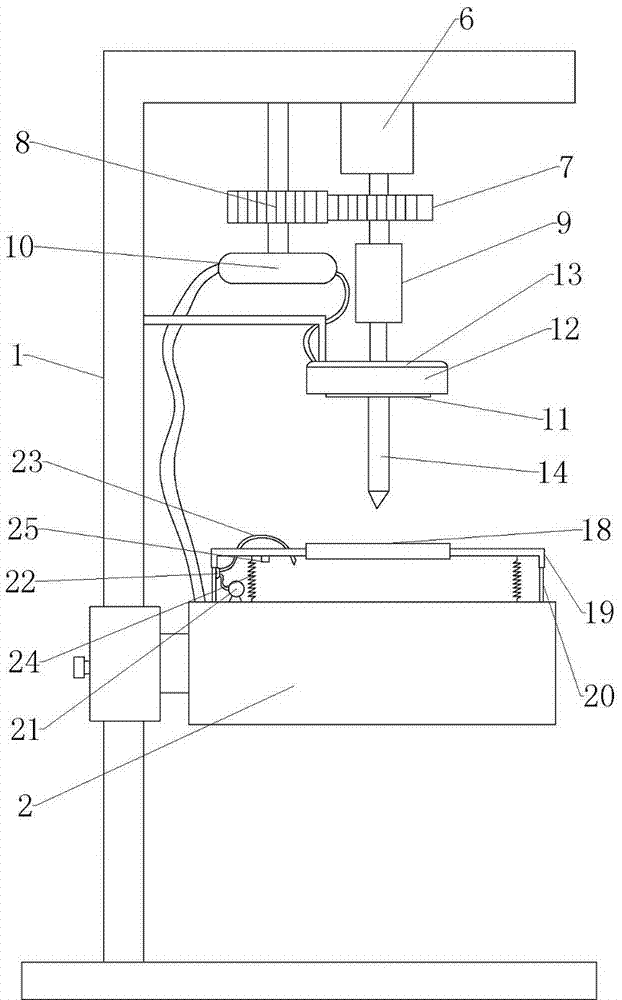

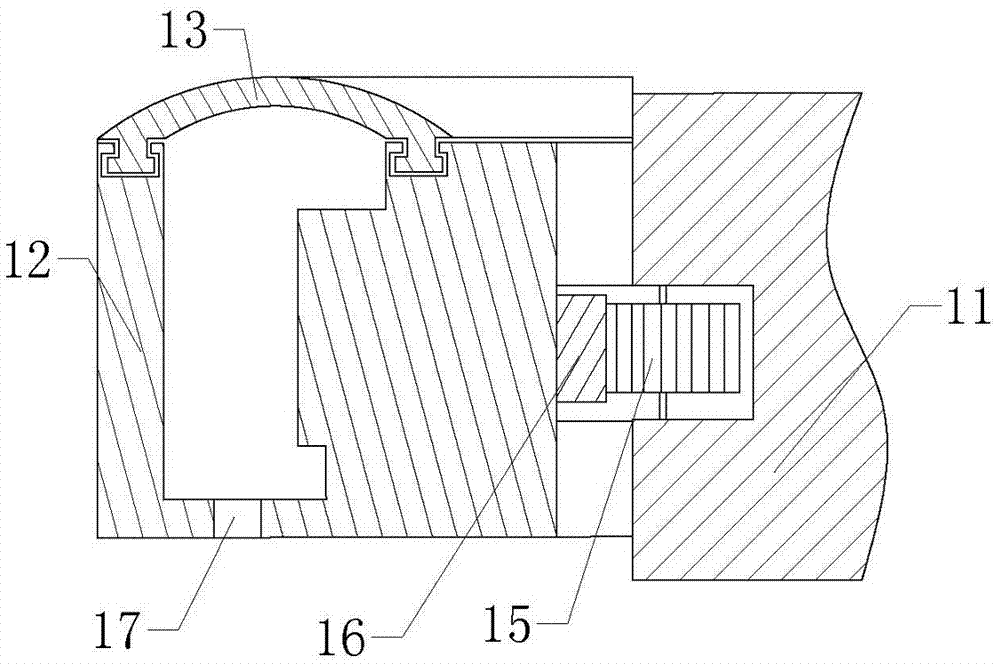

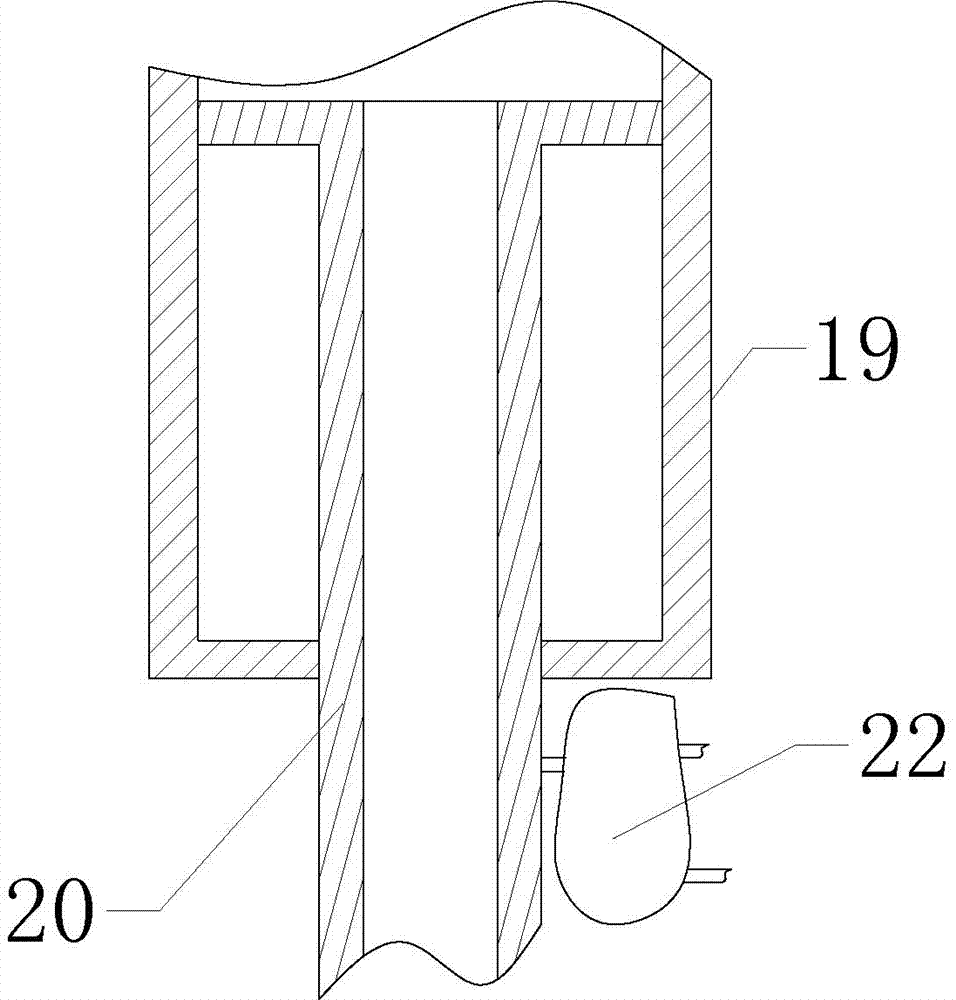

[0019] The reference signs in the drawings of the description include: frame 1, console 2, roller 3, cavity 4, water tank 5, motor 6, first gear 7, second gear 8, cylinder 9, sealing shell 10, turntable 11 , shaft sleeve 12, cover 13, drill bit 14, third gear 15, internal gear 16, water curtain hole 17, annular groove 18, outer tube 19, inner tube 20, air pump 21, air bag 22, air outlet pipe 23, spring 24 , switch 25.

[0020] Example basic reference Figure 1~Figure 4 Shown: an anti-splash plate punching device, including a frame 1, on which a console 2 is connected by bolts, and four rollers 3 are installed on the operation surface of the console 2, and the middle part of the console 2 Have a cavity 4, there are water tanks 5 on the left and right sides of the console 2, the water tanks 5 are connected, a motor 6 is installed on the frame 1 above the console 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com