Cigarette packet sampling-inspection method capable of avoiding unloading of trays from conveying line

A technology for conveying lines and cigarette packs, which is applied in transportation, packaging, packaging, and packaging protection. It can solve problems such as damage, affecting the moisture content of pallets, and pallet deformation, so as to reduce investment, reduce production and operation costs, and reduce damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

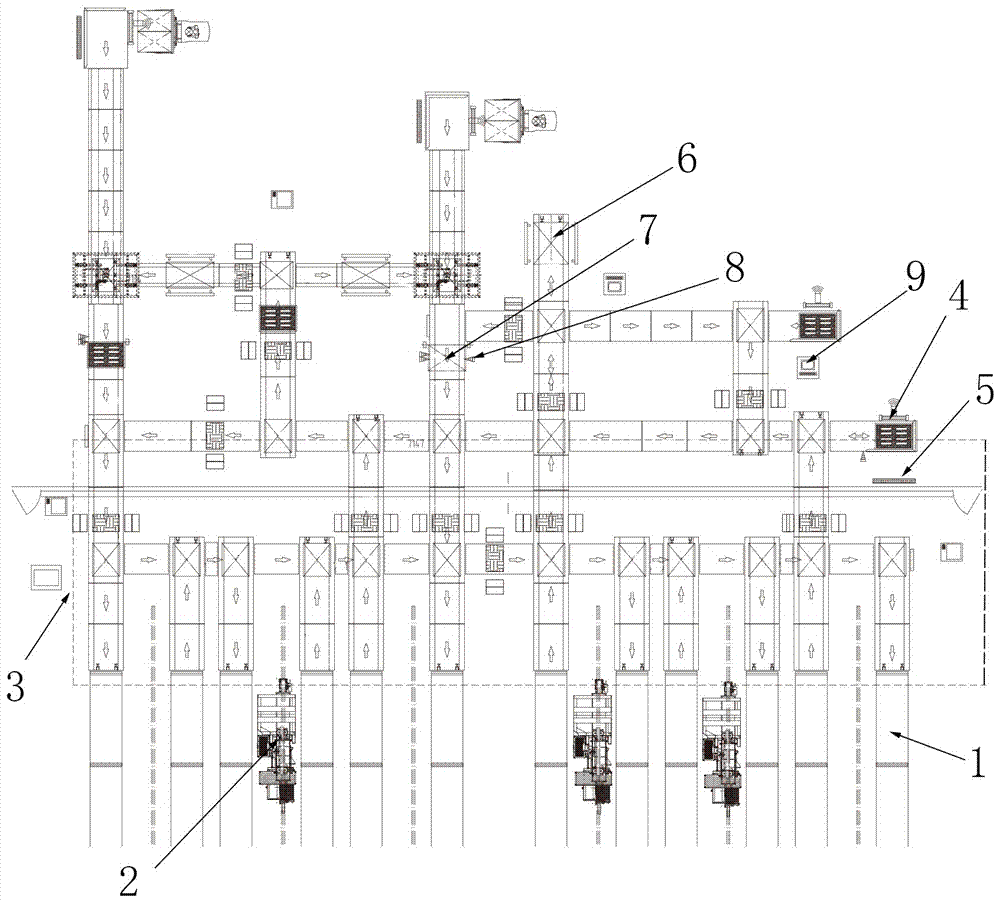

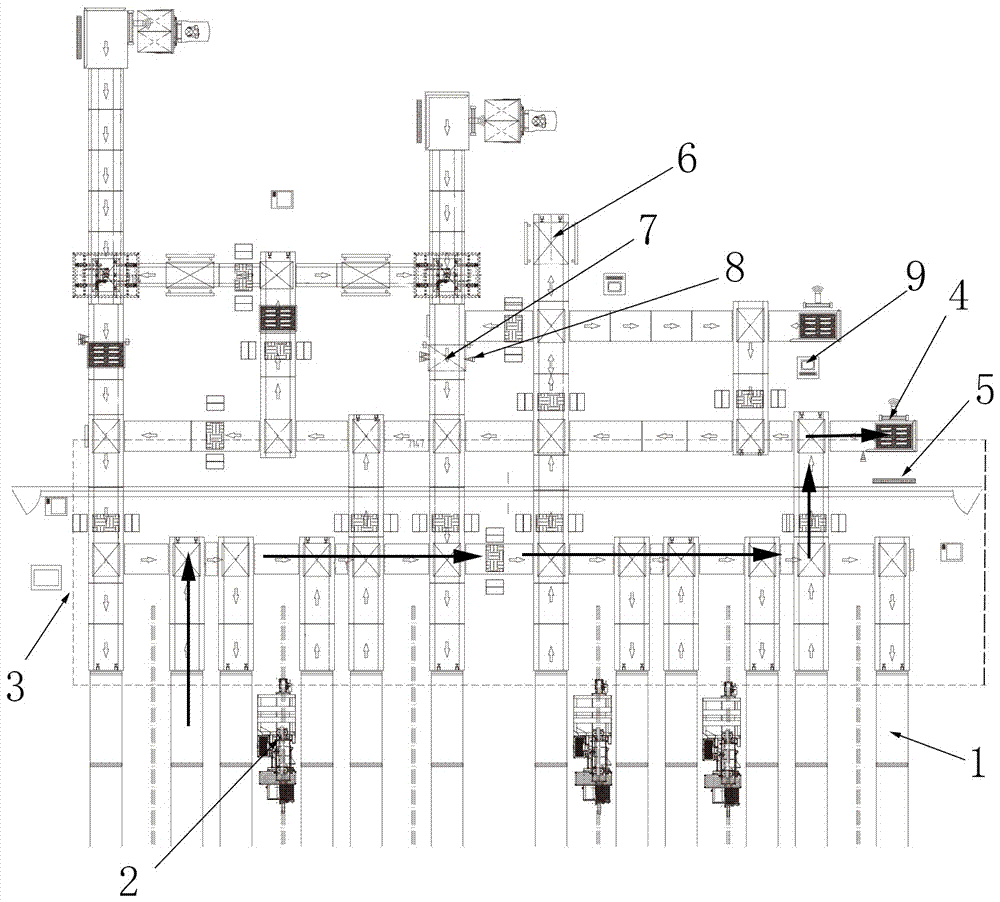

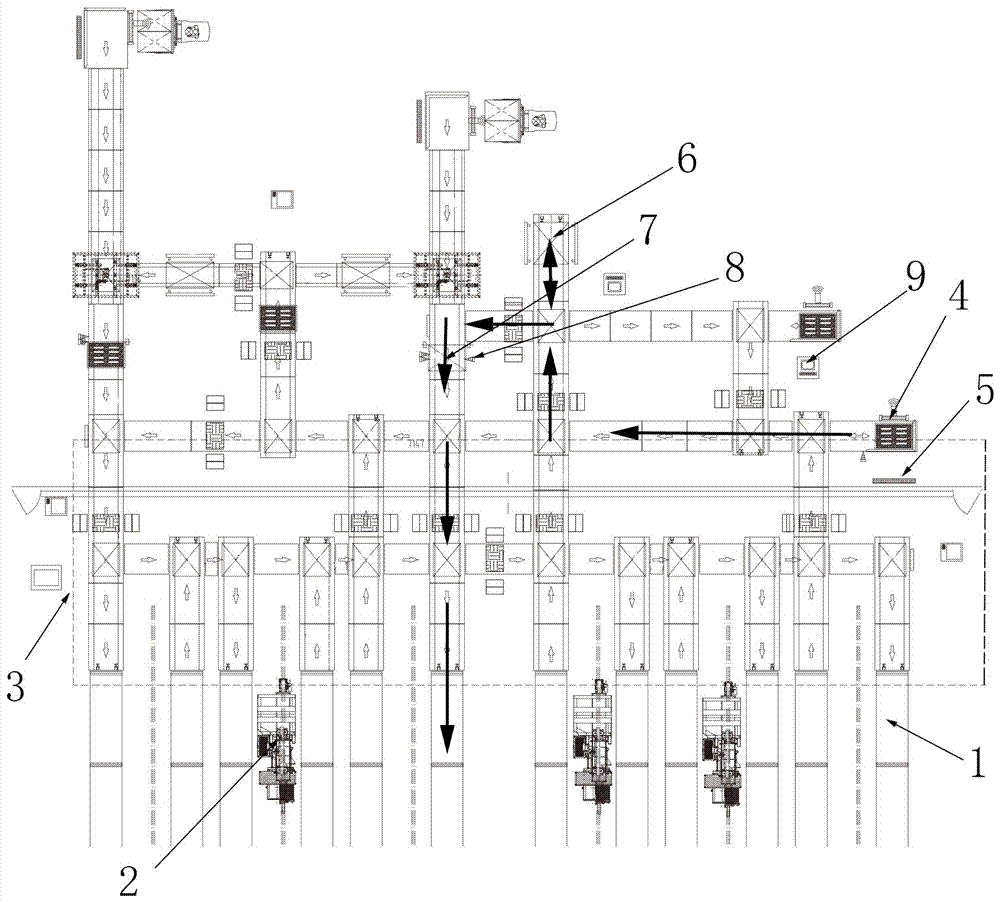

[0018] See attached picture. The cigarette packet sampling inspection system involved in this embodiment includes: an elevated warehouse 1, a stacker 2, an inbound and outbound transportation system 3, a sampling inspection platform 4, an LED display 5, a stacking station 6, a shape inspection station 7, and a code reading station. 8, electronic control system, enterprise's production information management system MES, warehouse management system WMS and WMS operation terminal 9; elevated warehouse 1 is used to store cigarette packs with trays and tray groups; stacker 2 is used to pick and place cigarettes packs and tray groups; inbound and outbound transportation system 3 is used to transfer inbound and outbound cigarette packs and tray groups; sampling inspection platform 4 is the sampling inspection station for cigarette packs to be inspected, and operators can take the cigarette packs to the destination by holding a cart; The LED display screen 5 is used to display the inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com