Double-layer automatic conveying device for tire tube and green tire

An automatic conveying device and conveying device technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of high labor intensity for operators, skewed placement of tire tubes, and damage to the ring mouth, so as to improve automation And the degree of intelligence, reduce labor intensity, improve the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

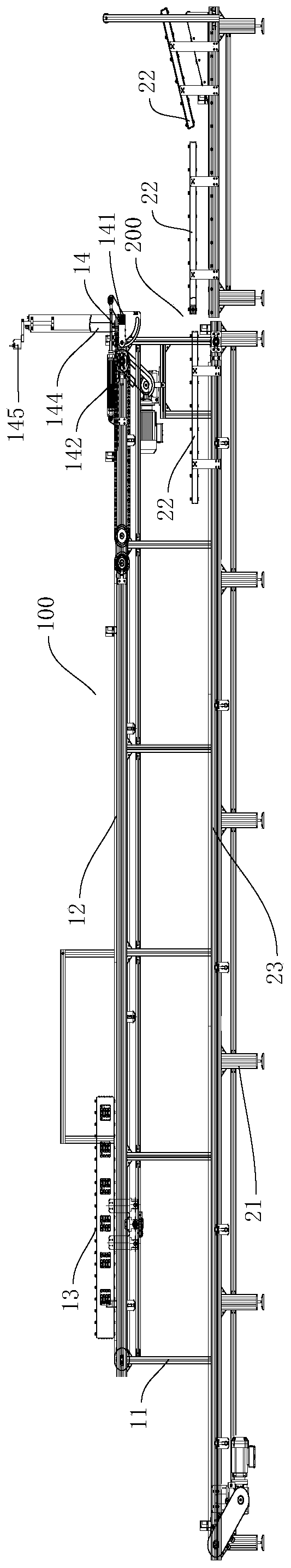

[0031] Such as figure 1As shown, a double-layer automatic conveying device for a tire tube and a green tire includes a first conveying device 100 for accepting a tire tube formed by a first-stage forming machine and transporting the tire tube to the operation place of a second-stage forming machine and for Undertake the tire blank formed by the second-stage forming machine and reversely transport the tire blank to the second conveying device 200 at the operation place of the first-stage forming machine,

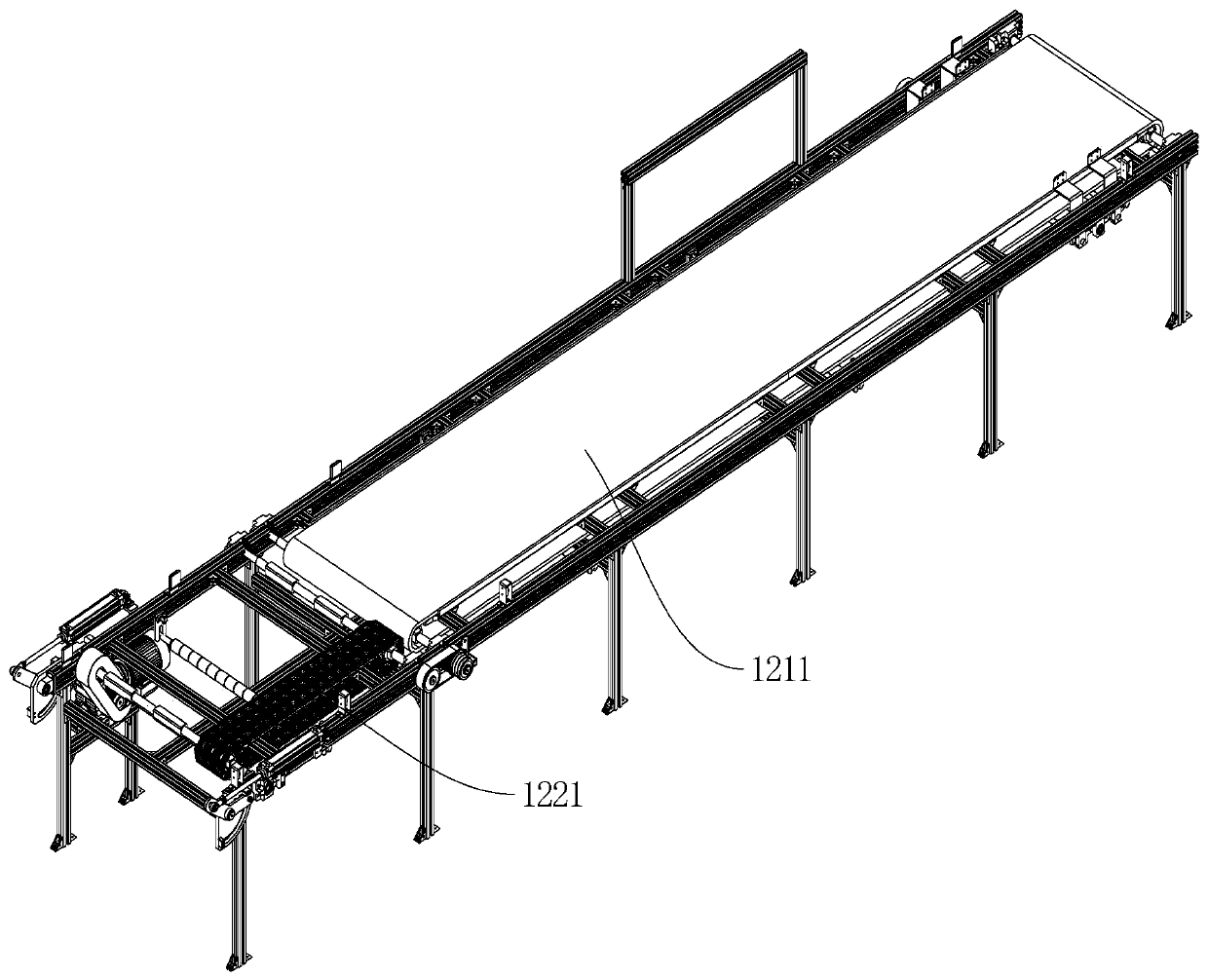

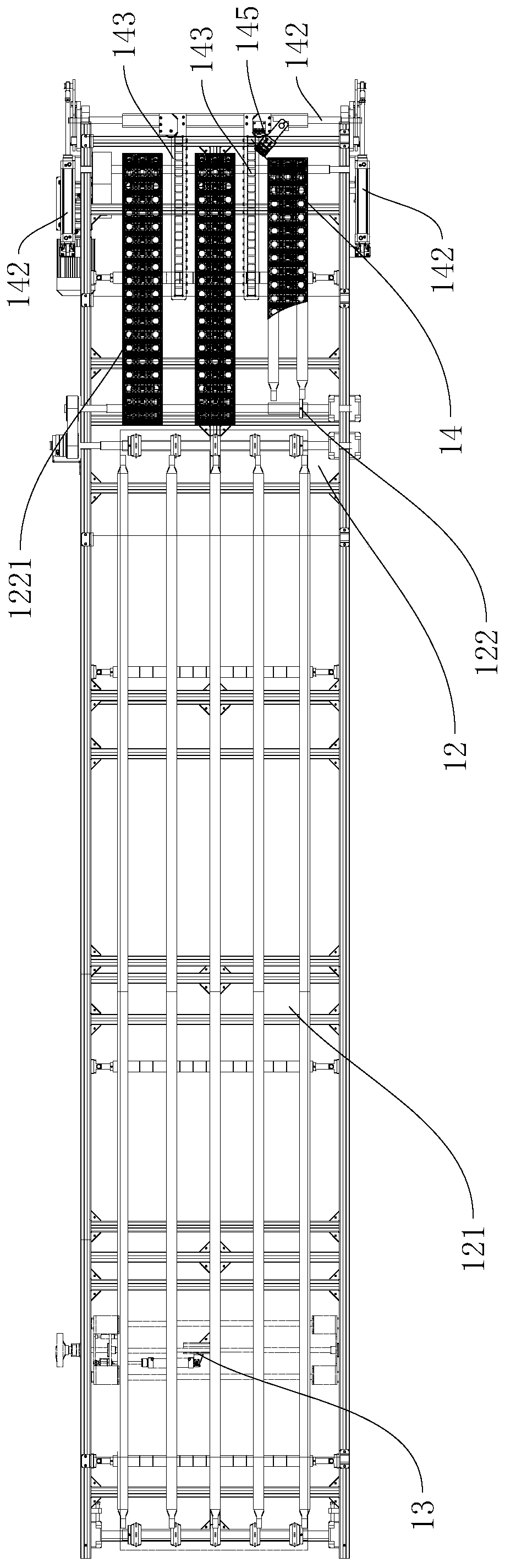

[0032] to combine figure 2 , image 3 As shown, the first conveying device 100 includes a first frame 11, a carcass conveying device 12 arranged on the first frame 11, a centering device 13 and an overturning device 14,

[0033] The tire tube conveying device 12 is used to accept a tire tube formed by a forming machine and deliver the tire tube to the turning device 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com