Two-section-type righting electric pole correction device

A correction device, a two-stage technology, applied in building types, buildings, towers, etc., can solve the problems of short strokes of safety hydraulic jacks, inconvenient daily life of residents, affecting power transmission, etc., to avoid safety accidents and avoid correction accuracy. Low, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

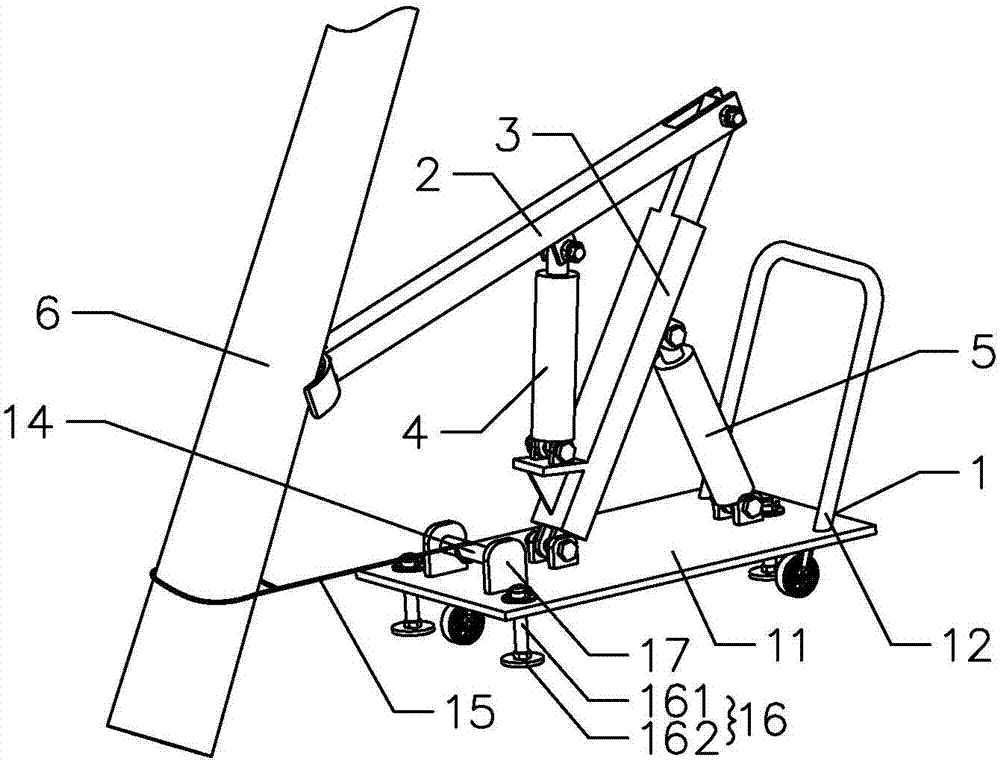

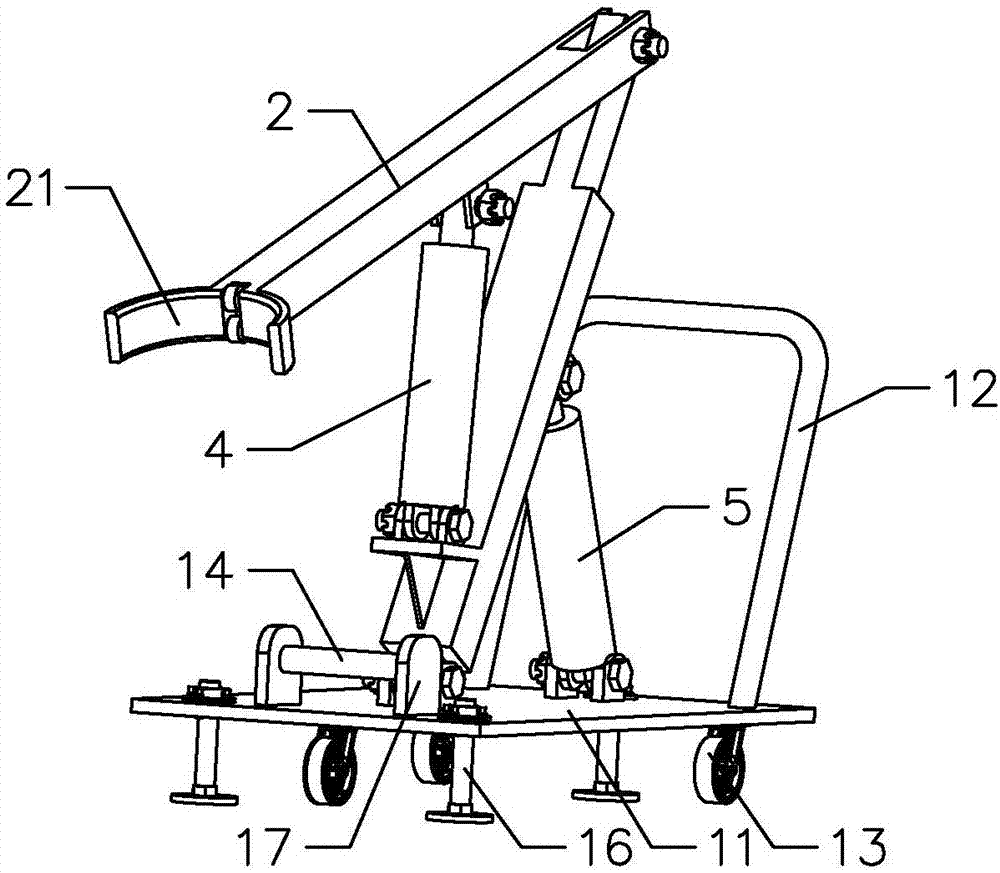

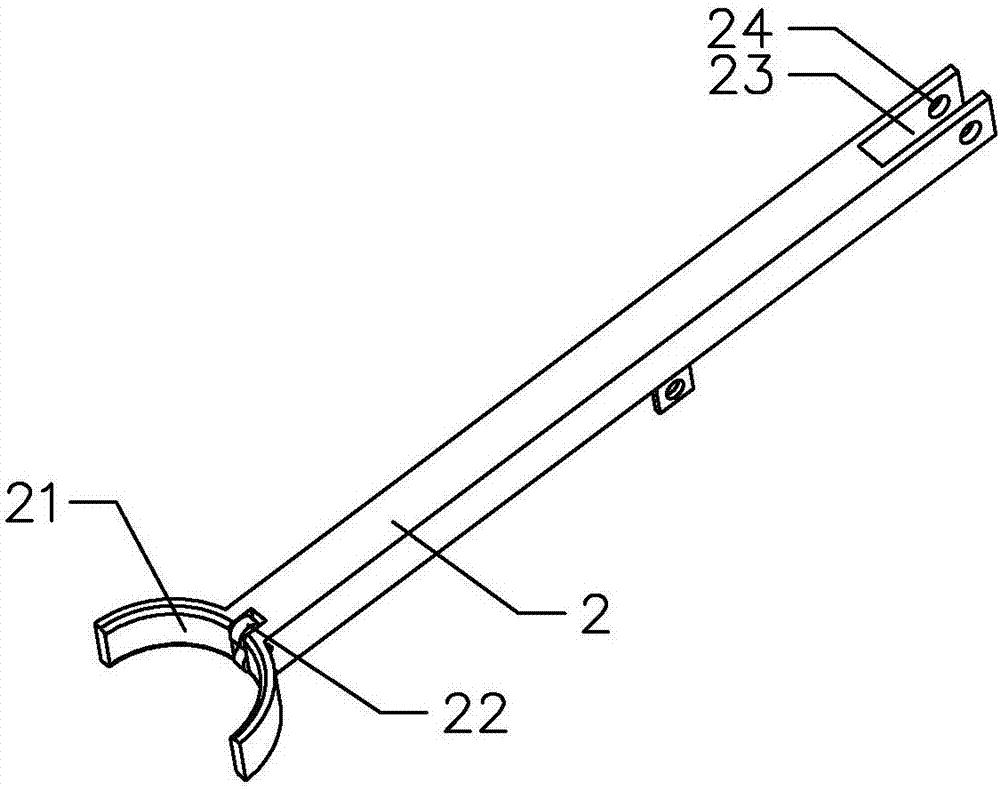

[0035] Such as Figures 1 to 5 As shown, the present invention provides a two-stage righting pole correction device, comprising a workbench 1, a first righting arm 2, a first jack 4 for pushing the first righting arm 2, a second righting arm 3 and a push The second jack 5 of the second righting arm 3, the bottom of the second righting arm 3 is fixed on the workbench 1, the top of the second righting arm 3 is rotationally connected with one end of the first righting arm 2, and the first righting arm 2 The other end of the pole 6 conflicts.

[0036]In this embodiment, the first jack 4 is operated to push the first righting arm 2 to realize the first section of righting of the electric pole 6, and the second jack 5 is operated to push the second righting arm 3, and the second righting arm 3 Promote the first righting arm 2 to realize the second stage righting of the electric pole 6, by setting the first righting arm and the second righting arm, and the first righting arm and the...

Embodiment 2

[0048] The difference between this embodiment and the first embodiment lies in that the shapes of the first righting arm and the second righting arm are different.

[0049] In this embodiment, both the first righting arm and the second righting arm are in the shape of a circular tube. The structures and beneficial effects of other parts not described are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0051] The difference between this embodiment and the first and second embodiments is that the first righting arm is different.

[0052] In this embodiment, the first righting arm includes a fixed section and a telescopic section inserted in the fixed section. The telescopic section can be stretched and retracted in the fixed section to change the overall length of the first righting arm, further increasing the work of the electric pole correction device. The stroke further improves the scope of application of the pole correction device. The structures and beneficial effects of other parts not described are the same as those of Embodiments 1 and 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com