Electric AMT gear selecting and shifting mechanism

A gear selection and gear selection technology, which is applied to mechanical equipment, transmission control, and components with teeth, etc., can solve problems such as difficulty in applying gearboxes, difficult processing, and limited output shifting force of the shift lever. , to achieve the effect of reducing the vertical layout space, compact structure layout and prolonging the working stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

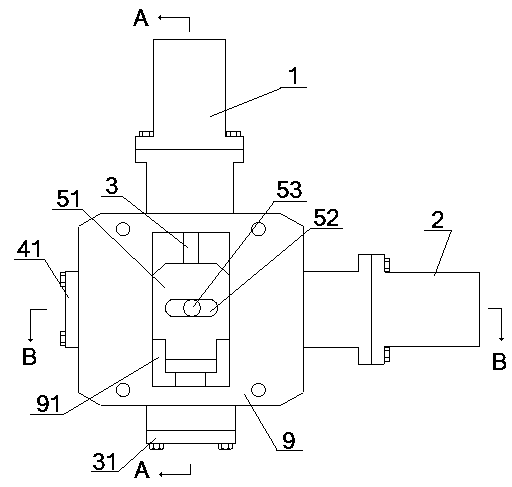

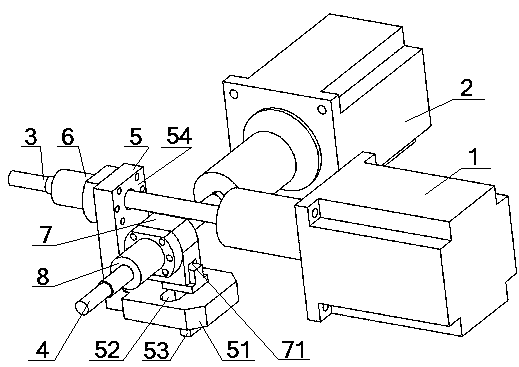

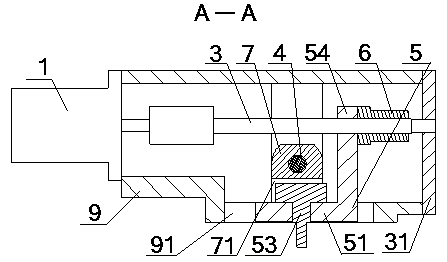

[0044] see Figure 1 to Figure 5 , an electric AMT gear selection mechanism, including a gear selection drive motor 1 and a gear shift drive motor 2 fixed on a housing 9, the output shaft of the gear selection drive motor 1 is connected to a gear selection wire by a gear selection coupling The head end of the rod 3 is driven and matched, the output shaft of the shift drive motor 2 is driven and matched with the head end of the shift screw 4 through the shift coupling, and the gear selection screw 3 and the shift screw 4 are mutually connected. The gear selection screw 3 is vertically arranged, and the gear selection screw 3 is driven and matched with the gear selection dial 53 along the central axis of the gear selection screw 3 through the gear selection slider 5; The gear shift dial 53 is driven and matched along the central axis of the gear shift screw 4; the middle part of the gear selection screw 3 passes through the gear selection slider 5 and is threaded with the gear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com