Adjustable hydraulic gear shaft transmission mechanism

A transmission mechanism and gear shaft technology, applied in engine control, engine components, machine/engine, etc., can solve the problems of increased sealing difficulty, high hydraulic adjustment pressure, and low adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

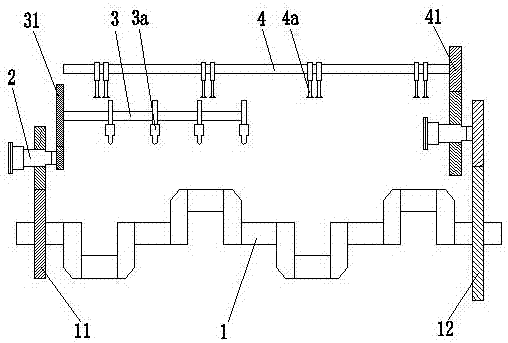

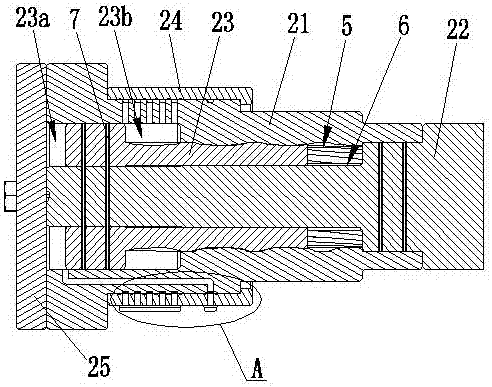

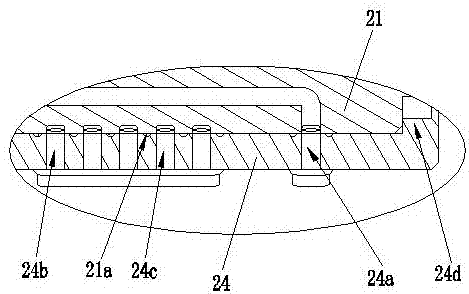

[0026] Such as Figure 1 to Figure 4 The example shown,

[0027] Description of icon numbers: crankshaft 1, free end gear 11, flywheel end gear 12, adjustment mechanism 2, outer shaft 21, high pressure sealing ring 21a, mandrel 22, adjustment shaft 23, left oil chamber 23a, right oil chamber 23b, oil delivery Valve 24, left injection hole 24a, right injection hole 24b, feedback hole 24c, rib 24d, cover plate 25, high pressure oil pump shaft 3, high pressure oil pump 3a, high pressure oil pump shaft gear 31, camshaft 4, air valve 4a, camshaft Gear 41, spiral tooth groove 5, spline tooth groove 6, sealing ring 7, pressure sensor 81, control system 82, oil return valve 83, hydraulic electric control valve 84, main hydraulic valve 85, hydraulic oil pump 86.

[0028] Such as Figure 1 to Figure 4 as shown,

[0029] An adjustable hydraulic gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com