Tail gas heating compartment square silencer for commercial vehicle

A technology for exhaust gas heating and commercial vehicles, which can be used in mufflers, exhaust devices, machines/engines, etc., to solve problems such as heat loss and achieve good muffling effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

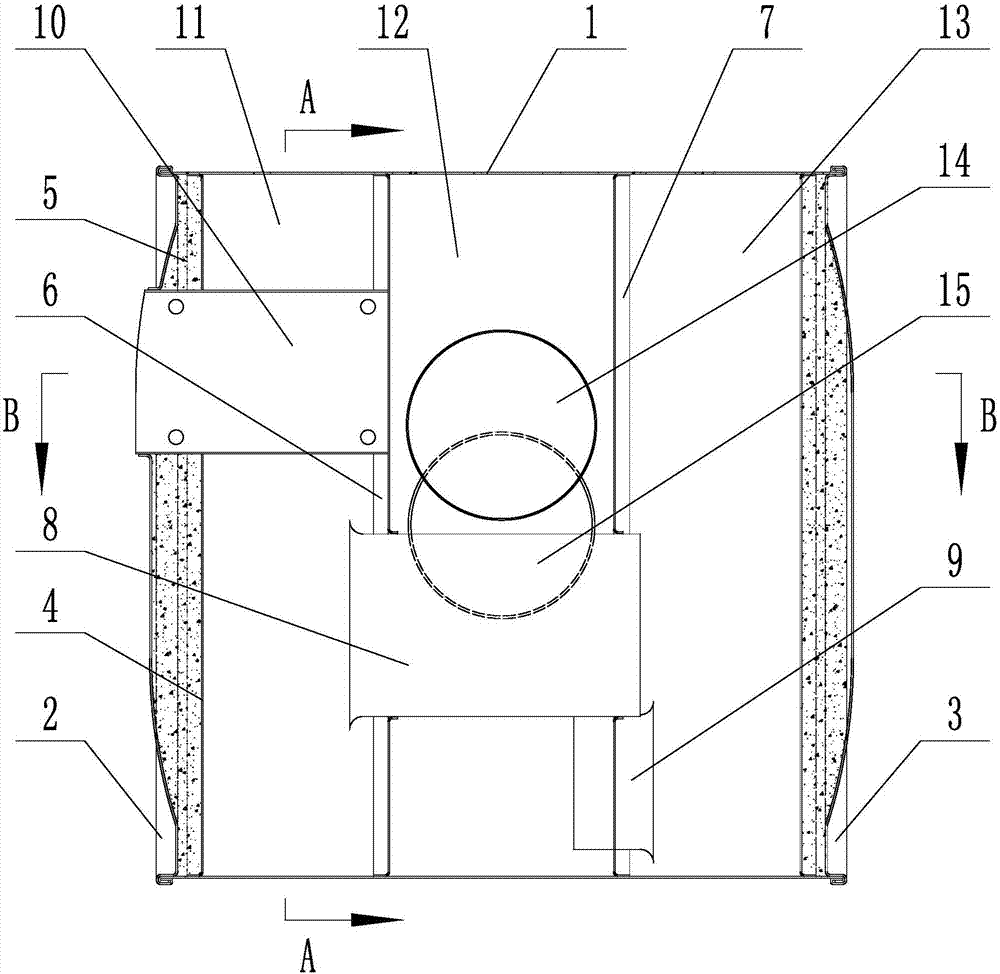

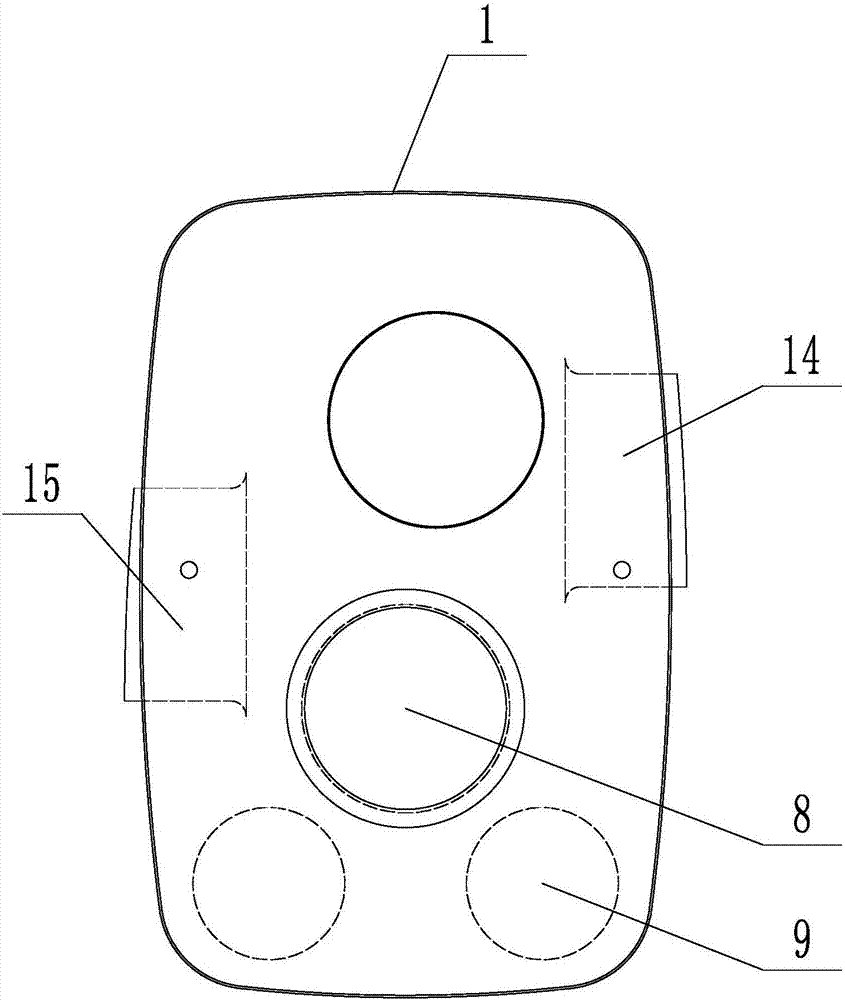

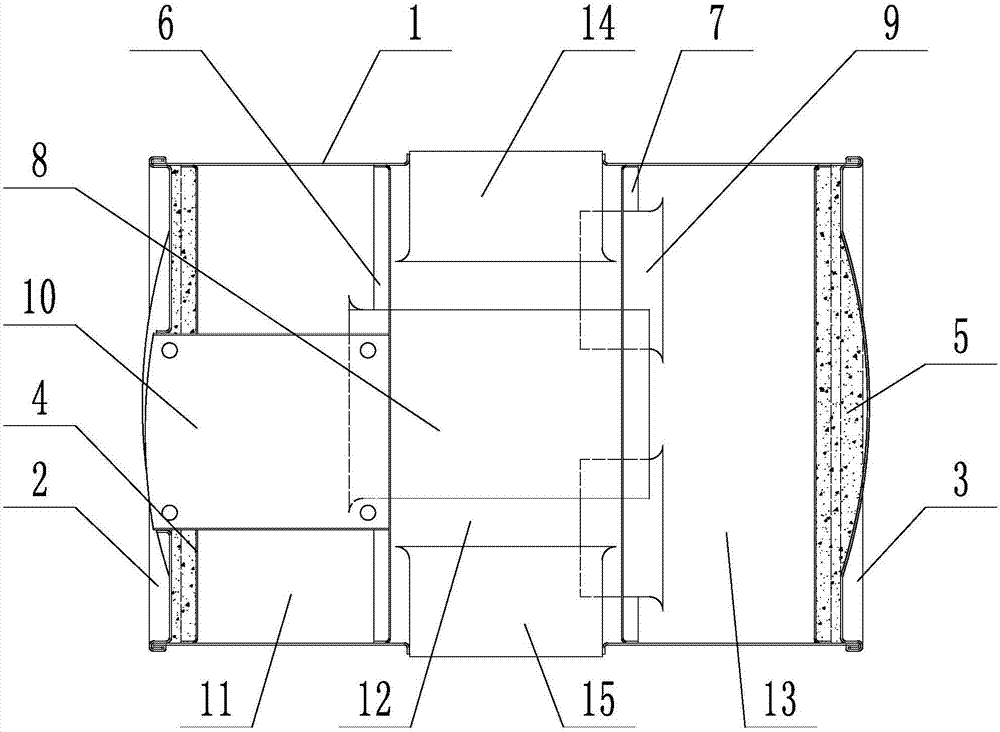

[0011] Such as Figure 1-3 As shown, the technical solution adopted by the present invention is: a commercial vehicle exhaust gas heating compartment side muffler, comprising a housing 1, a front end cover 2 and a rear end cover 3, the head and tail end of the housing 1 are respectively equipped with The front end cover 2 and the rear end cover 3, the inner side of the front end cover 2 and the rear end cover 3 are respectively installed with a group of screen plates 4 inside the housing 1, between the front end cover 2 and the screen plate 4, the rear end cover 3 Glass fibers 5 are filled between them and the net plate 4, a front partition 6 and a rear partition 7 are installed at the midline position inside the housing 1, and a penetrating wall is installed between the front partition 6 and the rear partition 7. The first middle pipe 8, the upper right and lower right of the first middle pipe 8 are located on the rear bulkhead 7, and a group of second middle pipes 9 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com