LED automobile dipped headlight of multiple reflection structure

A technology of multiple reflections and low beams, applied in the direction of headlights, reflectors, light sources, etc., can solve the problems of high power consumption, low light utilization rate, high luminous efficiency, etc., to prevent visual discomfort, uniform light mixing, The effect of improving the utilization rate of light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

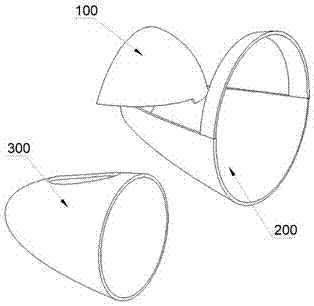

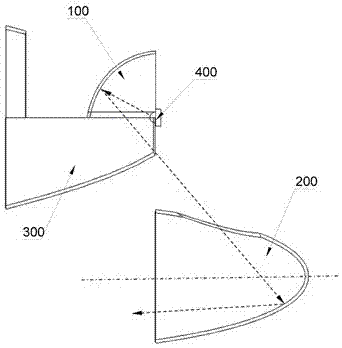

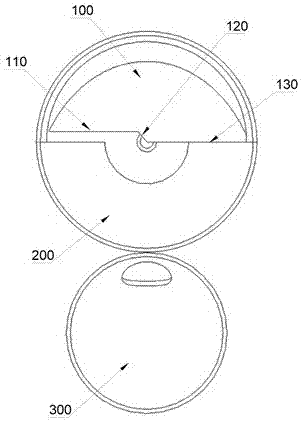

[0032] Such as Figure 1~6 , a kind of multi-reflection structure LED automobile low beam lamp, which includes an LED light source 400 with the normal direction of the light emitting surface facing the projection area, an ellipsoidal reflector 100 located obliquely above the LED light source 400, and a second LED light source located below the LED light source 400 A parabolic reflector 300 and a second parabolic reflector 200 positioned below the first parabolic reflector 300; the ellipsoidal reflector 100 includes an ellipsoidal first focus and an ellipsoidal second focus, and the first parabolic reflector 300 The focal point of the second parabolic reflector 200 overlaps with the first focal point of the ellipsoidal reflector 200; A cut-off structure with a cut-off line spot, the cut-off structure includes a protruding portion 130 at the bottom of the ellipsoidal mirror 100 , a beveled portion 120 adjacent to the protruding portion 130 , and a horizontal portion 110 adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com