Direct heating energy-saving heat pump water heater

A heat pump water heater, energy-saving technology, applied in fluid heaters, heat exchange equipment, high-efficiency regulation technology, etc. Improve performance, ensure stability, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

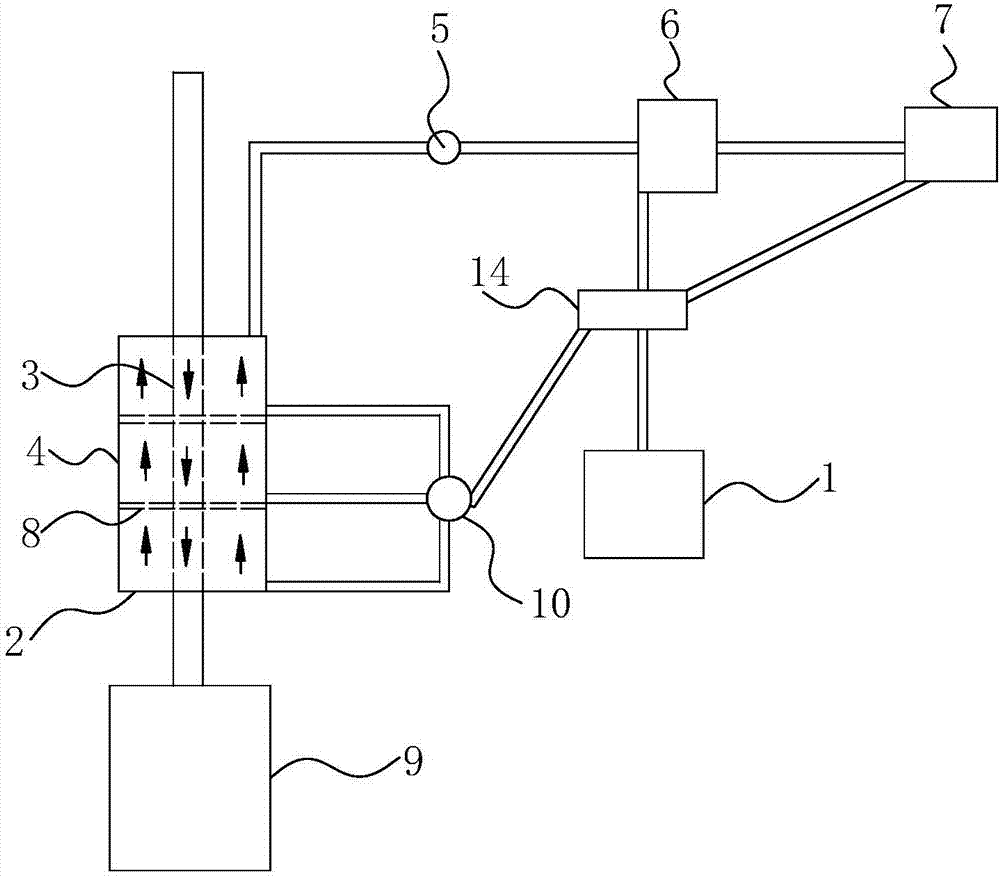

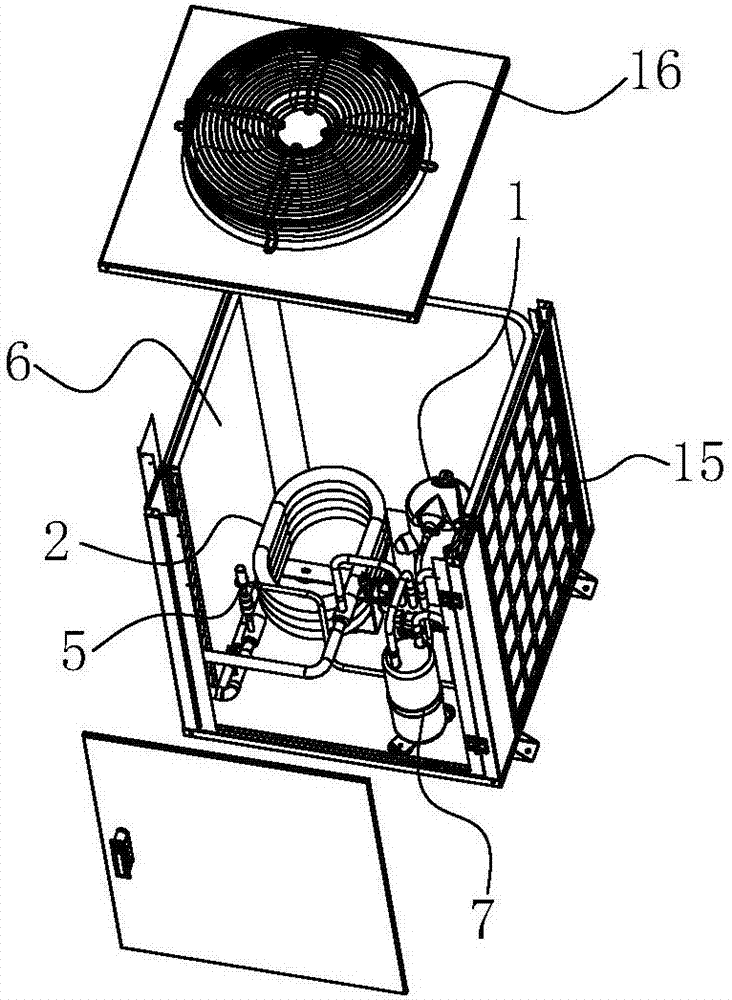

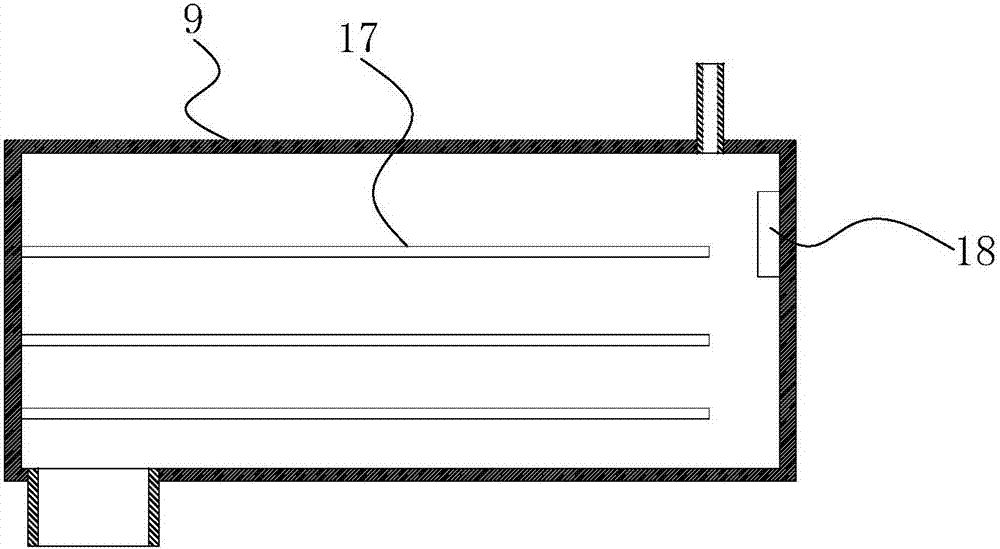

[0025] combine Figure 1-6 The shown direct heating energy-saving heat pump water heater includes a compressor 1 . The outlet of the compressor 1 is connected to the outer pipe 4 of the casing heat exchanger 2, the end of the outer pipe 4 of the casing heat exchanger 2 is connected to the electronic expansion valve 5, the heat exchange medium flows in the outer pipe 4, and the electronic expansion valve 5 The expansion valve 5 is connected to the evaporator 6 , the evaporator 6 is connected to the gas-liquid separator 7 , and the gas-liquid separator 7 is connected to the inlet of the compressor 1 .

[0026] The outer tube 4 of the casing heat exchanger 2 is evenly divided into multiple sections along the flow direction of the heat exchange medium, and the heat exchange medium may be nitrogen, ammonia or other gases that play the same role. The outlet of the compressor 1 is respectively connected to each section of the outer pipe 4 through a diverter valve 10, and a one-way v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap