Reinforcements for plate heat exchangers and plate heat exchangers

一种板式换热器、加强件的技术,应用在间接换热器、换热器类型、换热器外壳等方向,能够解决变形或开裂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

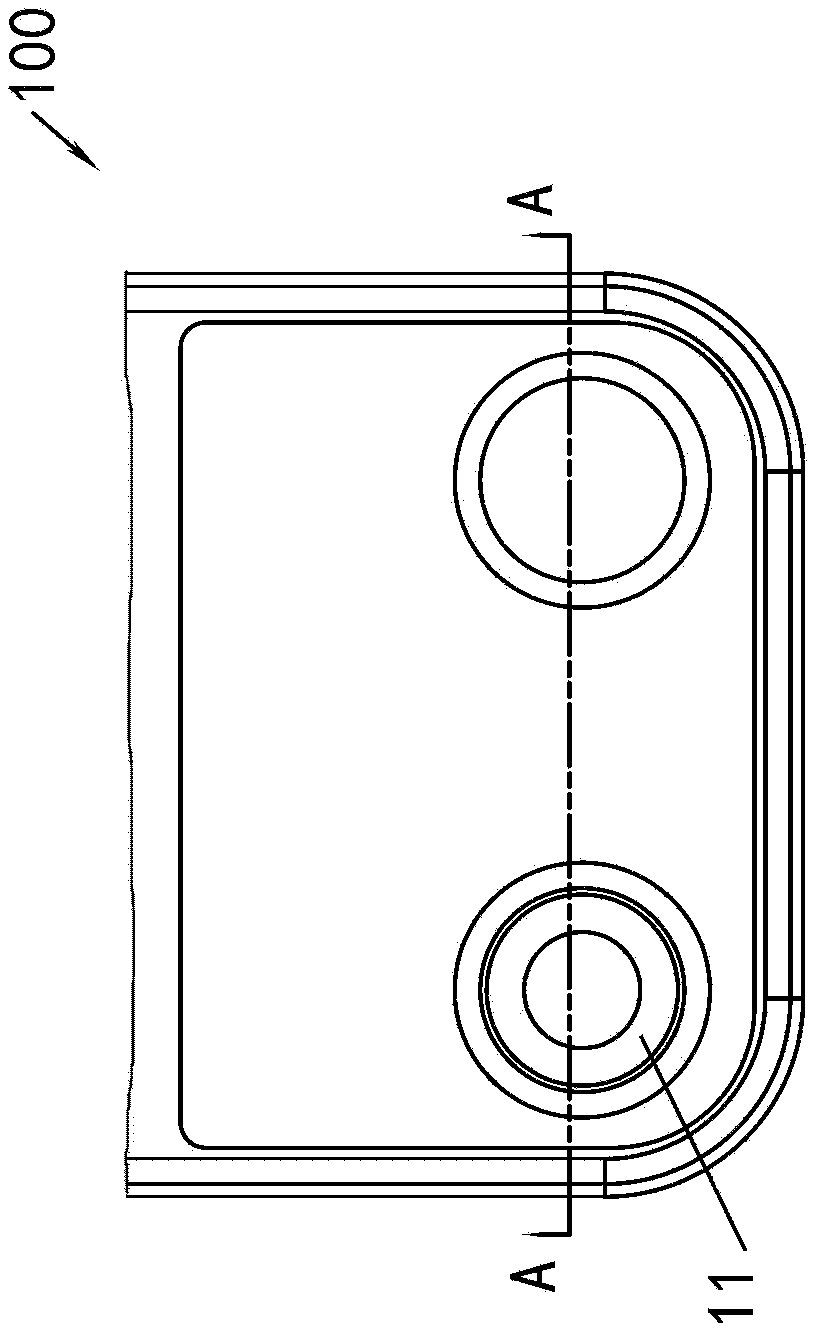

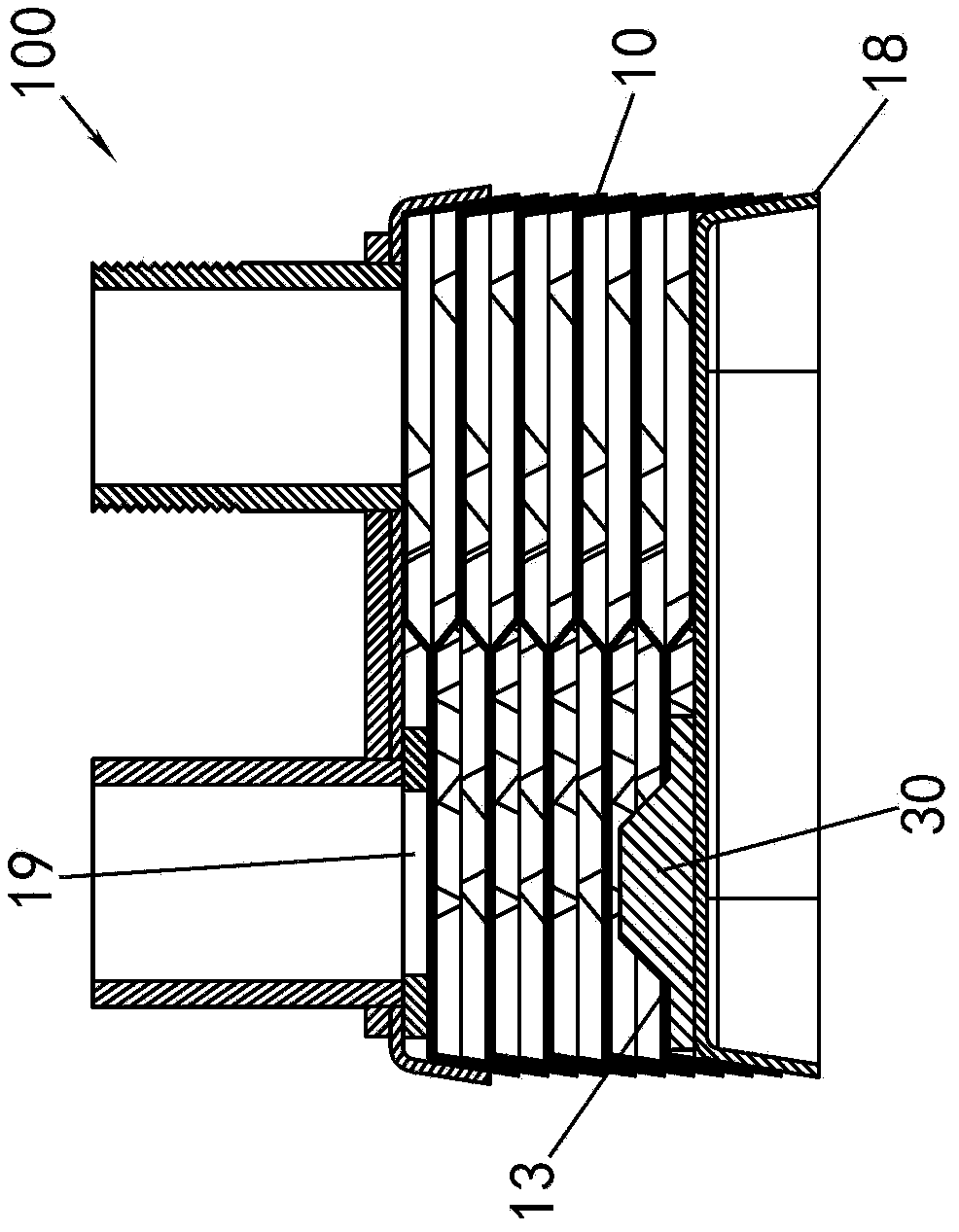

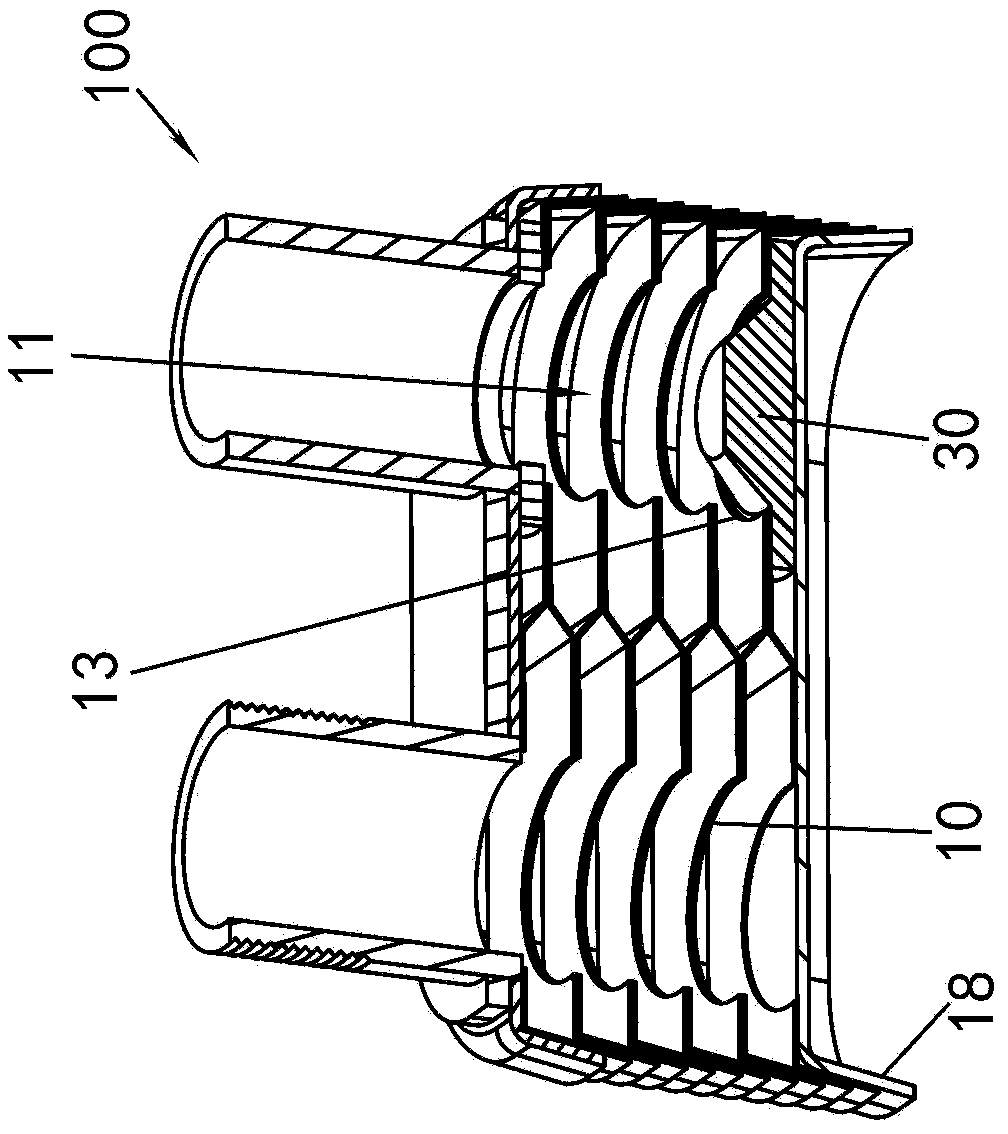

[0070] Such as Figures 1 to 39 As shown, the plate heat exchanger 100 according to the embodiment of the present invention includes: a plurality of heat exchange plates 10; a heat exchange space formed between adjacent heat exchange plates 10 in the plurality of heat exchange plates 10; forming The heat exchanger channel 11 in the heat exchange plate 10, the heat exchanger channel 11 is used for the heat exchange medium to flow into or out of the heat exchanger 100, and the openings 13 of a plurality of heat exchange plates 10 constitute the heat exchanger channel 11; And a reinforcing member 30 for reinforcing the surrounding area of the opening 13 of at least one heat exchange plate 10 . The reinforcing member 30 may have a substantially disc shape and may be formed by sheet metal.

[0071] Such as Figures 1 to 6 And as shown in 19 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com