Wiring structure for low voltage signal double winding transformer partial discharge test

A dual-winding transformer, partial discharge technology, applied in the parts, instruments, measuring electrical variables and other directions of electrical measuring instruments, can solve the problem of low test voltage, affecting the safe and reliable operation of ultra-high voltage transformers of transformers, and overloading of transformer pressurized sides. Equipment capacity and other issues to achieve the effect of reducing requirements and increasing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

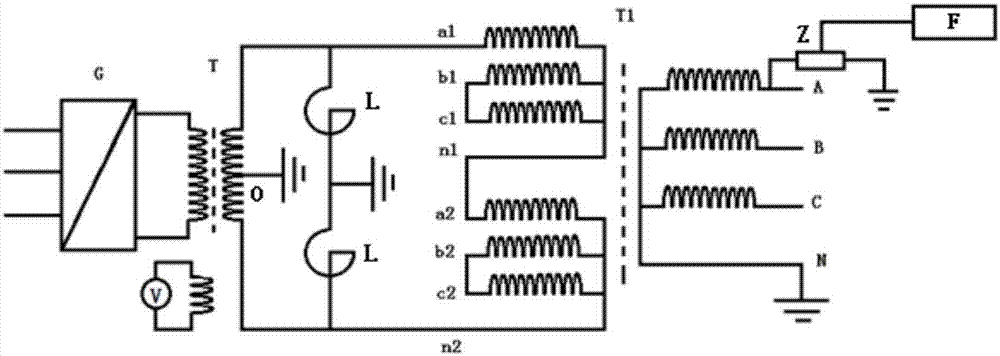

[0019] Referring to the accompanying drawings, a wiring structure for a partial discharge test of a double-winding transformer on the low-voltage side, including a partial discharge-free variable frequency power supply G, a non-partial discharge excitation transformer T, a tested low-voltage side double-winding transformer T1 and a partial discharge detector F;

[0020] The non-partial discharge variable frequency power supply G is connected to the input end of the non-partition discharge excitation transformer T, the output of the non-partition discharge excitation transformer T adopts a symmetrical output, and the output end of the non-partition discharge excitation transformer T has a first terminal and the second terminal, and the middle O of the first terminal and the second terminal is grounded; the first terminal and the second terminal are each connected to a compensation reactor combination, and the tail end of the compensation reactor combination grounding; the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com