Light emitting device having asymmetric light shape and manufacturing method thereof

A technology for a light-emitting device and a manufacturing method, which is applied in the directions of electrical components, circuits, semiconductor devices, etc., can solve the problems of increasing the size and space of the CSP light-emitting device, increasing the production cost, and lack of it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

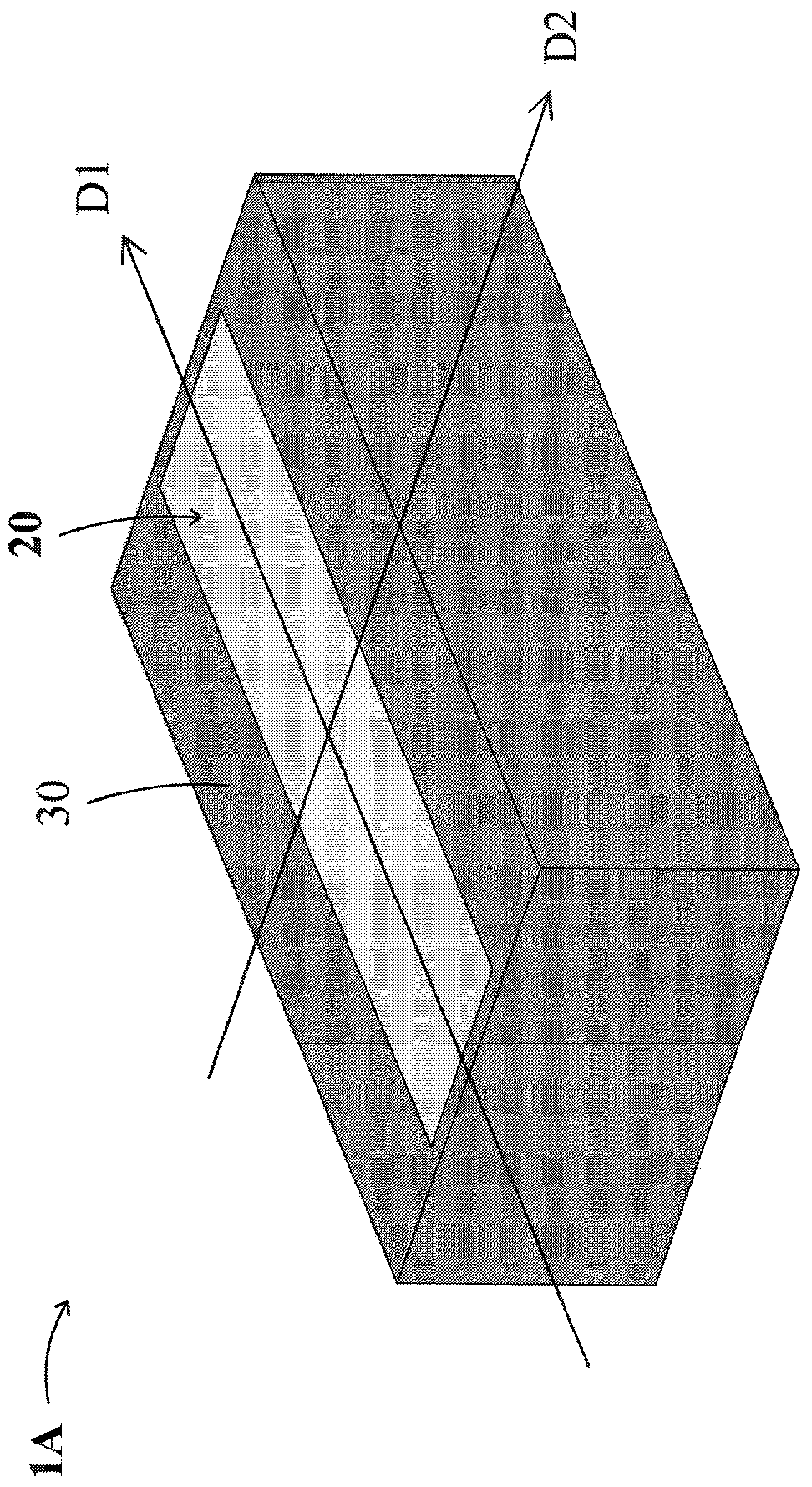

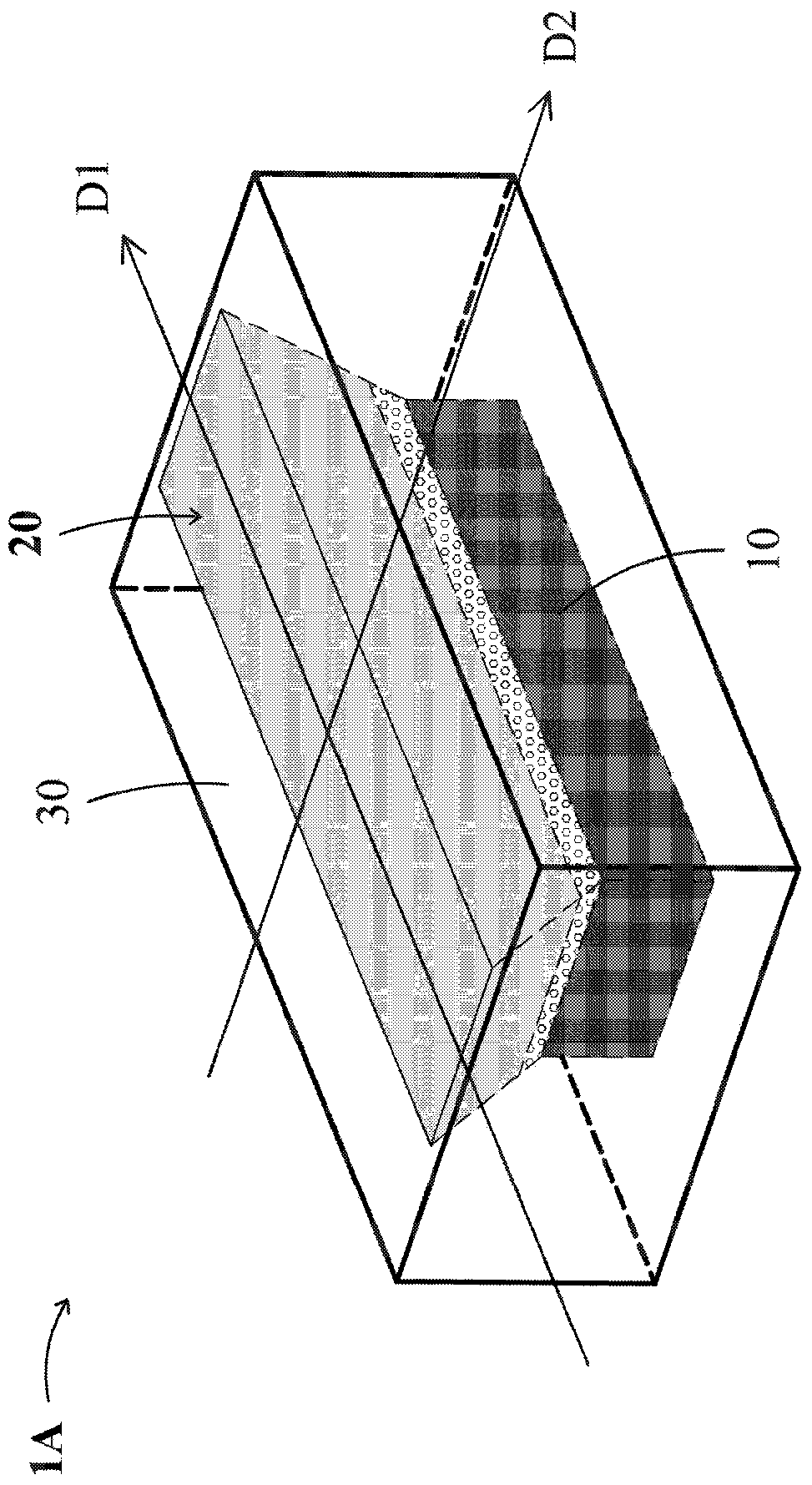

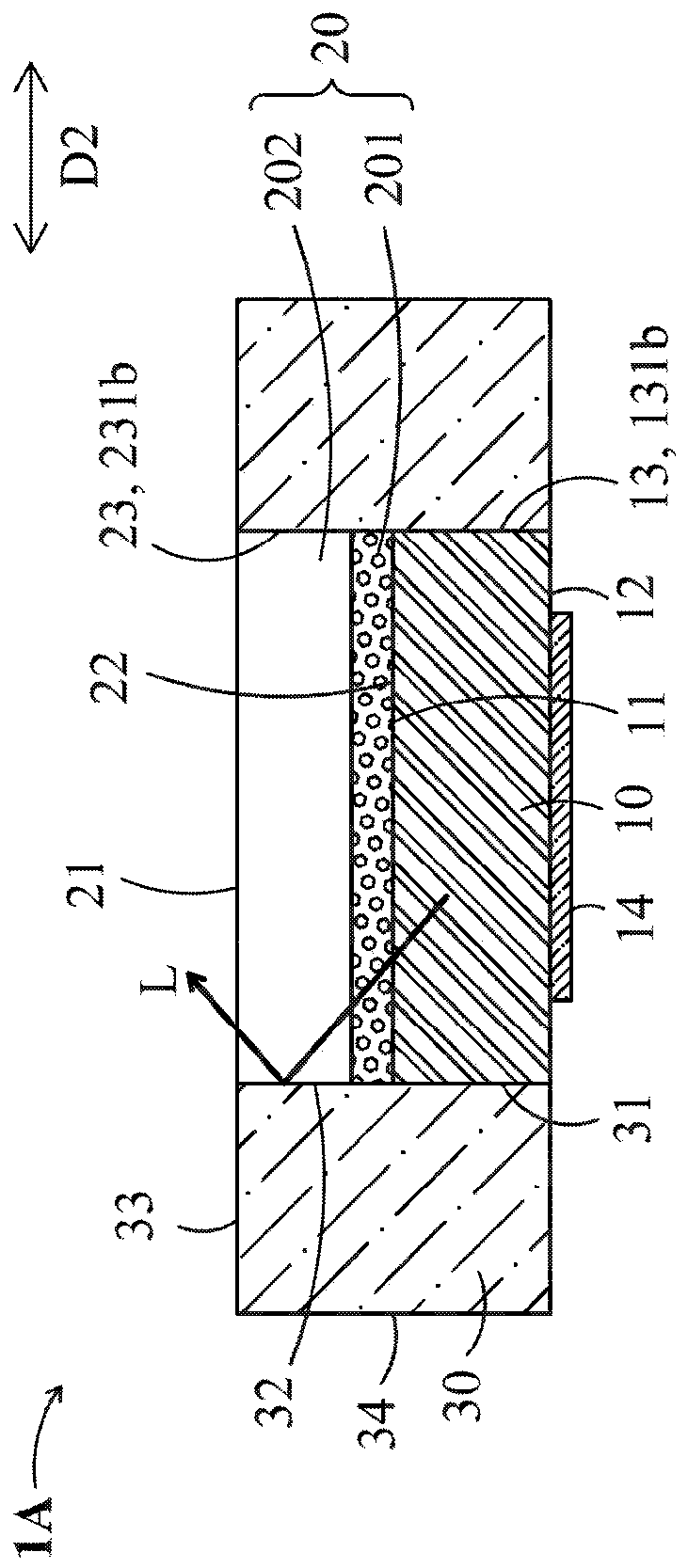

[0066] see Figure 1A to Figure 1D As shown, it is two perspective schematic diagrams and two cross-sectional schematic diagrams of the light emitting device according to the first preferred embodiment of the present invention. When the light emitting device 1A is used, it will occupy a certain area (not shown in the figure), and the area extends in a first horizontal direction D1 and a second horizontal direction D2, and the first horizontal direction D1 and the second horizontal direction D2 are mutually vertical, and each of the first horizontal direction D1 and the second horizontal direction D2 is perpendicular to the thickness direction (not shown) of the light emitting device 1A. The light emitting device 1A may include an LED chip 10 , a fluorescent structure 20 and a reflective structure 30 ; the technical content of these multiple components will be described in sequence as follows.

[0067] The LED chip 10 can be a flip-chip LED chip, and can have an upper surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com