Floatable electrical plug support assembly

A floating bracket and electric plug technology, which is applied in the installation of connecting parts and the device for connecting/disconnecting connecting parts, etc., can solve problems such as reducing the service life of electric plugs, and achieve the effect of improving service life and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

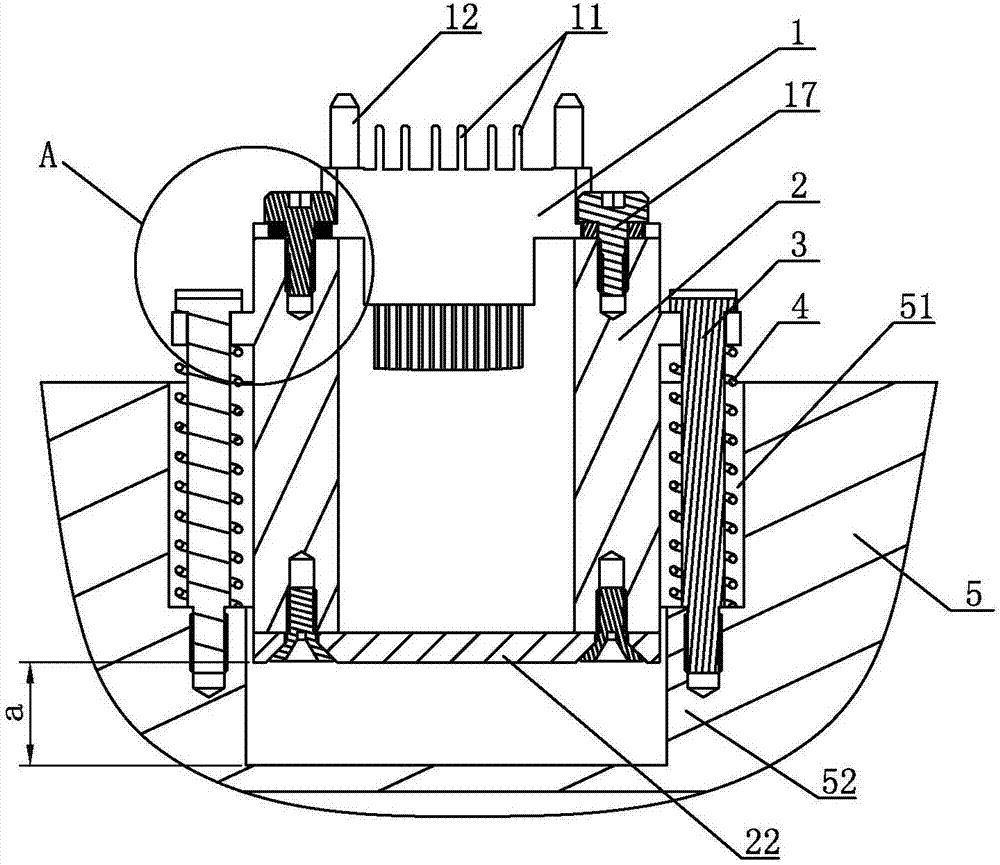

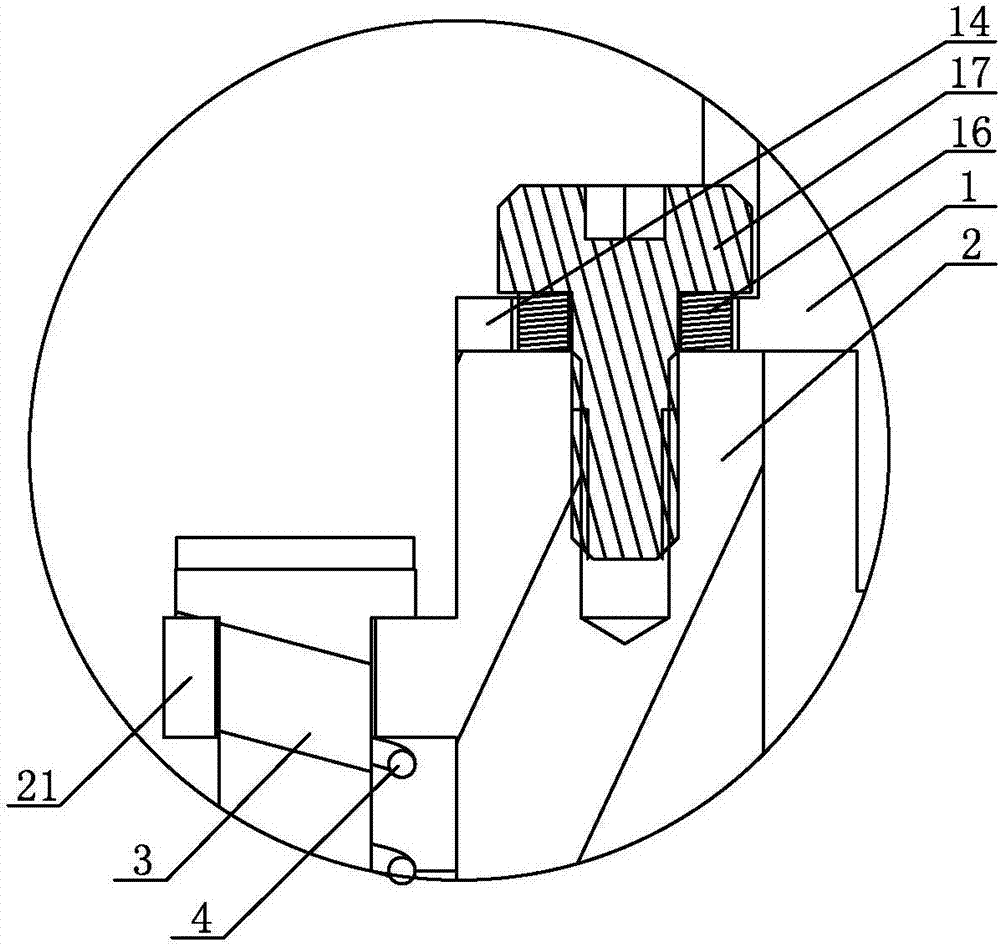

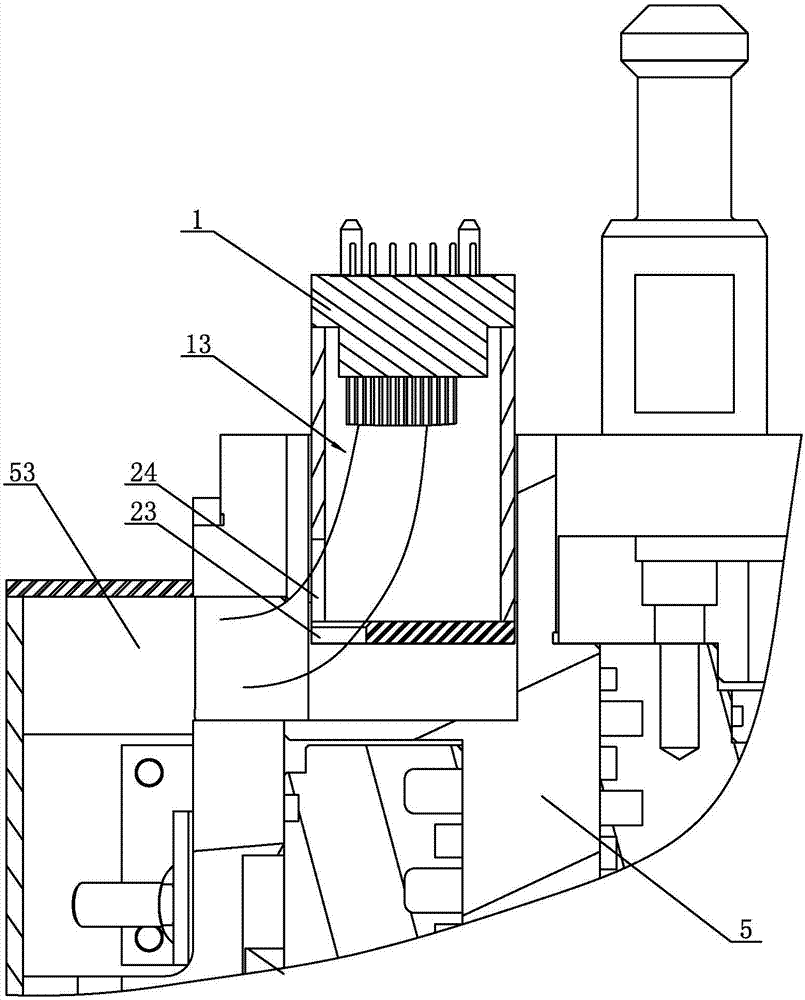

[0027]The floating electrical plug bracket assembly of Embodiment 1, as shown in the figure, the electrical plug includes a suitable sub-plug 1 and a female plug (not shown in the figure), and the sub-plug 1 is provided with several pins 11 and Three guide pins 12, the female plug is provided with several sockets (not shown in the figure) and three pin holes (not shown in the figure) that are compatible with several pins 11 and three guide pins 12, the The bracket assembly includes a floating bracket 2, four guide screws 3 and four springs 4, the floating bracket 2 is floatingly installed on the first machine tool component 5, and the first machine tool component 5 is provided with a concave cavity 51, and the bottom of the floating bracket 2 is arranged on In the concave cavity 51; four guide screws 3 are arranged at intervals along the circumferential direction of the floating support 2, each guide screw 3 passes through the floating support 2 and is threadedly connected with...

Embodiment 2

[0030] The floating electrical plug bracket assembly of Embodiment 2, as shown in the figure, the electrical plug includes a suitable sub-plug 1 and a female plug (not shown in the figure), and the sub-plug 1 is provided with several pins 11 and Three guide pins 12, the female plug is provided with several sockets (not shown in the figure) and three pin holes (not shown in the figure) that are compatible with several pins 11 and three guide pins 12, the The bracket assembly includes a floating bracket 2, four guide screws 3 and four springs 4, the floating bracket 2 is floatingly installed on the first machine tool component 5, and the first machine tool component 5 is provided with a concave cavity 51, and the bottom of the floating bracket 2 is arranged on In the concave cavity 51; four guide screws 3 are arranged at intervals along the circumferential direction of the floating support 2, each guide screw 3 passes through the floating support 2 and is threadedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com