Stator of linear motor and linear motor and compressor

A linear motor and straight stator technology, applied in electromechanical devices, electrical components, magnetic circuit shape/style/structure, etc., can solve problems such as magnetic loss, reduce magnetic loss, reduce cost, and reduce magnetic permeability resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

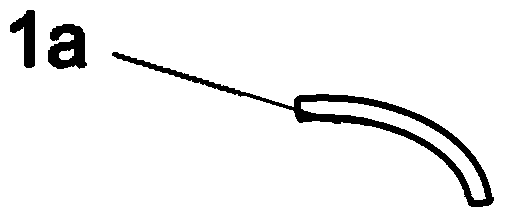

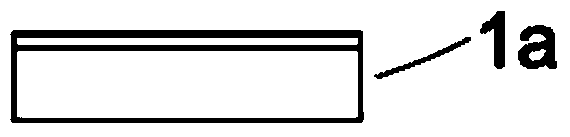

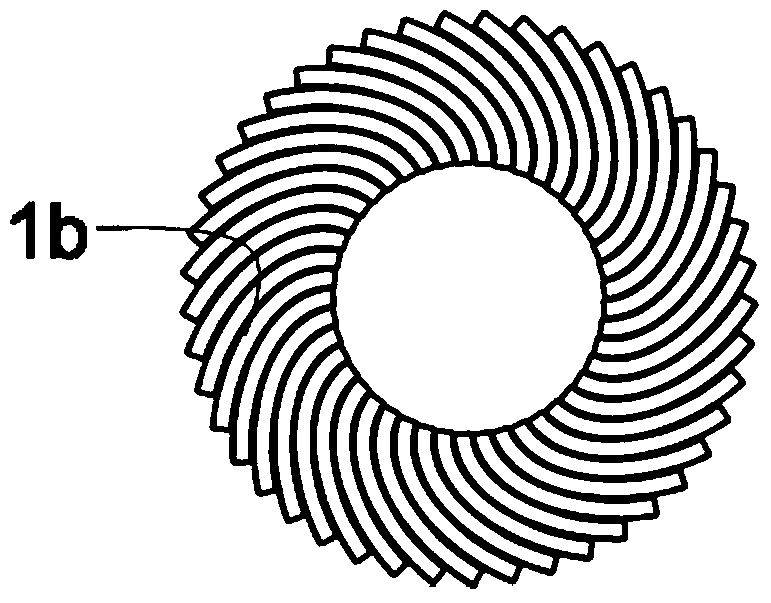

[0064] As shown in Figure 1-3, an inner stator for a linear motor, the inner stator adopts the following Figure 1a-1b The first type of inner stator sheet 1a is processed. The first type of inner stator sheet 1a is stamped from a straight stator sheet into an arc-shaped stator sheet according to a certain radian, and it can also be bent by other methods. Several first-type inner stator pieces 1a are welded into an annular first-type inner stator 1b (such as Figure 2a-2b As shown), the design principle of the arc is that the adjacent first inner stator pieces 1a are tightly fitted, and there is no gap as much as possible;

[0065] Because the outer circle of the inner stator 1b is made up of the side surfaces of a piece of plate, it is not too smooth, so secondary processing can be carried out. On the basis of the first type of inner stator 1b, its outer circumference is further cut to form as Figure 3a-3b The second inner stator 1c of the structure shown.

[0066] The nu...

Embodiment 2

[0070] As shown in Figure 4-6, an inner stator used for a linear compressor motor, wherein the inner stator adopts such as Figure 4a-4b The second type of inner stator sheet 2a after the arc stamping process shown is welded, and the second type of inner stator sheet 2a after the arc stamping process has grooves, so that the third type of stator sheet 2a welded by it Inner stator 2b (such as Figures 5a-5b There is a groove a on the outer periphery of the above), the groove a can be used to place magnets, so that the magnets and the third inner stator 2b form a whole without additional magnet fixing devices. On the basis of the third inner stator 2b, its outer circumference is further cut to form as Figures 6a-6b In the fourth type of inner stator 2c shown, the above-mentioned adjacent second type inner stator pieces 2a are tightly bonded without gaps; the number of second type inner stator pieces 2a is determined by the thickness of each second type inner stator piece 2a A...

Embodiment 3

[0075] A stator for a linear compressor motor, including an inner stator and an outer stator, as shown in FIG. The first type of outer stator 3b mentioned above, the second type of inner stator 1c is arranged in the inner ring of the first type of outer stator 3b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com