Wear sensing device having a housing

A technology of sensing device and wear sensor, which is applied in transportation and packaging, vehicle trackless testing, construction, etc., can solve problems such as premature breakage, unallowable circuit protection, and inappropriateness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

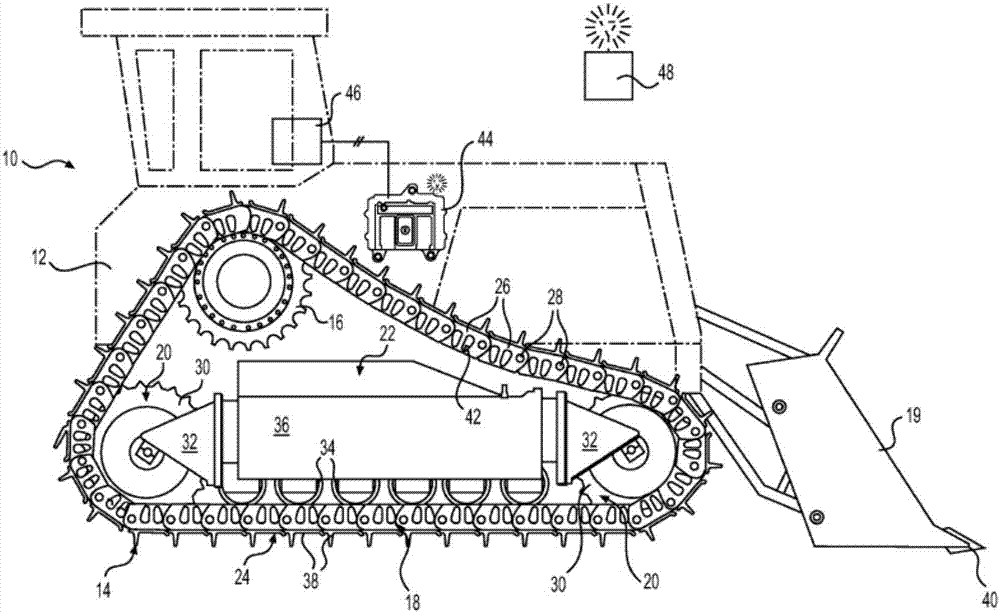

[0015] figure 1 An exemplary tracked machine 10 is shown consistent with the disclosed embodiments. Tracked machine 10 may embody any machine that is driven, propelled, positioned, and / or steered by operation of a "continuous" tracked traction device. Such machines may include, for example, track tractors, skid steer loaders, bulldozers, excavators, backhoes, track loaders, front shovels, wire rope shovels, or any other type of track steerable machine. Machine 10 may include a frame 12 and a pair of track assemblies 14 (only one shown) secured to frame 12 on opposite sides of machine 10 . Track assembly 14 may include a drive sprocket 16 coupled to a drive mechanism (not shown), and a chain assembly 18 operatively coupled to the drive mechanism via drive sprocket 16 and configured for propelling machine 10 . Machine 10 may also include work implement 19 .

[0016] The drive mechanism may include one or more components configured to generate a torque output. For example, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com