Anti-torsion crack and abrasion-resistant rubber core of blowout preventer

A blowout preventer and anti-twist technology, which is used in wellbore/well components, earthwork drilling, sealing/packaging, etc. Protection and other issues, to achieve the effect of not easily falling apart and twisting, good stability, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

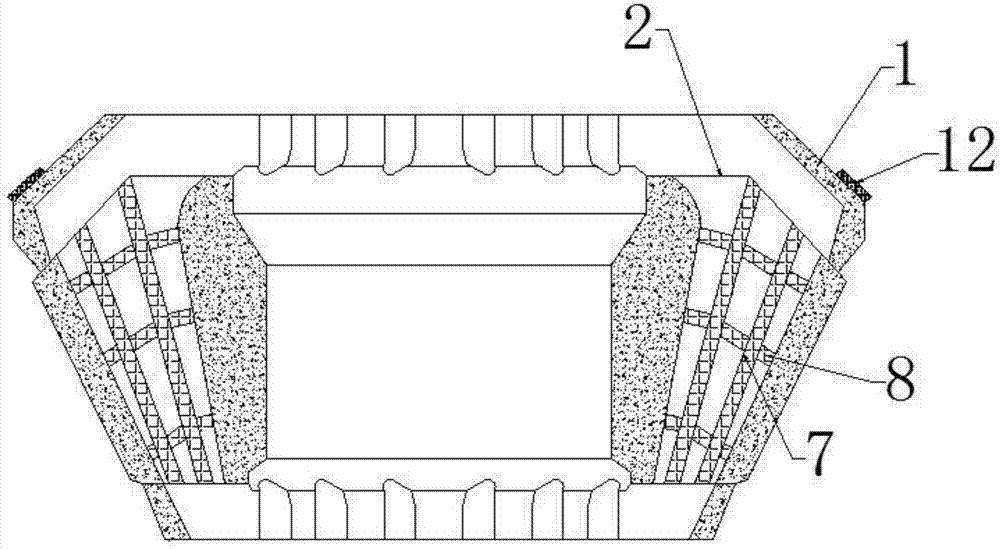

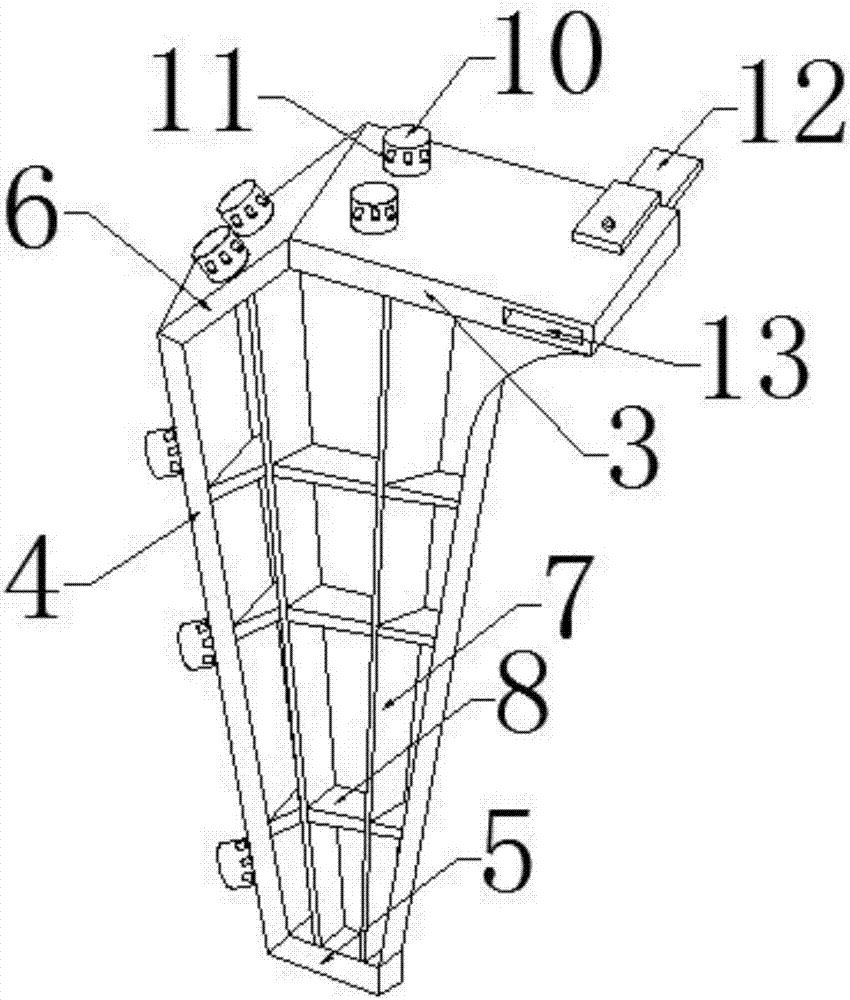

[0031] like Figure 1-7 As shown, an anti-twist and anti-wear BOP rubber core includes a rubber body 1 and a support body 2 evenly distributed in the rubber body 1. The support body 2 includes a top plate 3, a vertical plate 4 and a bottom plate 5, and the vertical plate 4 is arranged between the top plate 3 and the bottom plate 5, and a sloping plate 6 is also connected between the top plate 3 and the vertical plate 4, and a vertical plate is also connected between the top plate 3 and the bottom plate 5, and between the sloping plate 6 and the bottom plate 5 The support plate 7, a horizontal support plate 8 is also provided between the vertical plate 4 and the vertical support plate 7, and between adjacent vertical support plates 7. By replacing the strip-shaped reinforcing rib with a plate-shaped reinforcing plate, the stability of the support body 2 is better, and the horizontal support plate 8 between the top plate 3 and the bottom plate 5, and between the inclined plate 6...

Embodiment 2

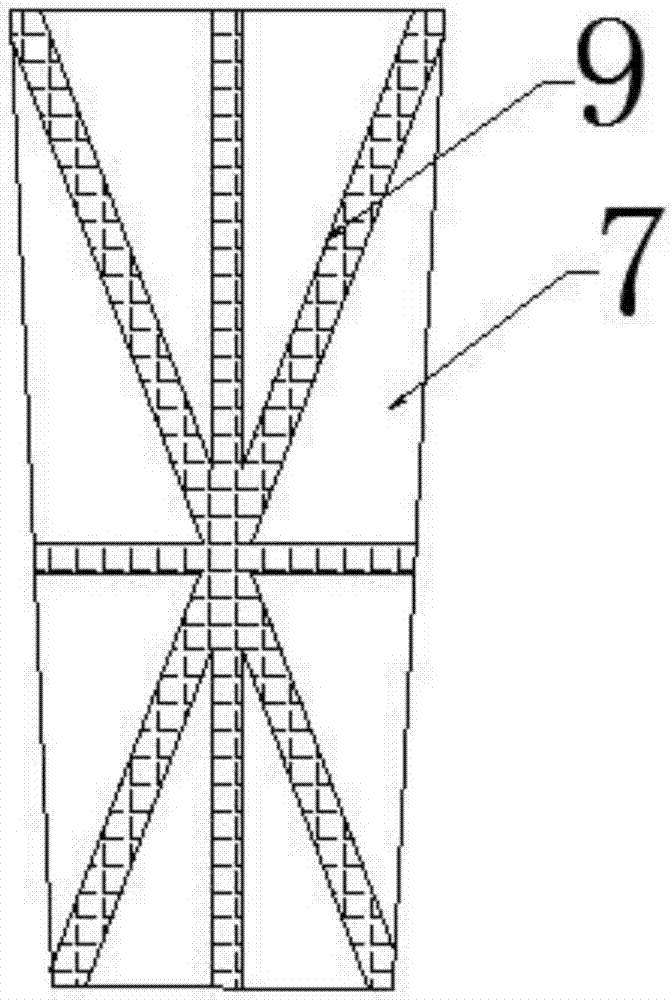

[0033] This embodiment is further defined on the basis of the above embodiments. In order to solve the problem that the rubber core will be twisted due to the oblique force generated when the drill pipe 24 is screwed in and out, the horizontal support plate 8 and the vertical The support plates 7 are provided with rice-shaped reinforcing ribs 9 . The rice font reinforcing rib 9 is arranged on the surface of the horizontal support plate 8 and the vertical support plate 7, and the end of the rice font reinforcing rib 9 is connected with the edge of the horizontal support plate 8 and the vertical support plate 7, and the designed rice font The reinforcing rib 9 can well support and reinforce in eight directions. Compared with the existing single-line reinforcing rib, it has more supporting directions, and can well support the drill pipe 24 during rotation. The oblique force generated when turning in and out is supported, which greatly improves the supporting strength of the suppo...

Embodiment 3

[0036]This embodiment is further defined on the basis of the above embodiments. In order to solve the problem of dislocation between the support body 2 and the rubber body 1, the outer surfaces of the top plate 3, the vertical plate 4, the bottom plate 5 and the inclined plate 6 are A protruding block 10 inserted into the rubber body 1 is provided, and a reinforcing bar 11 inclined to the supporting body 2 is provided on the side wall of the protruding block 10 . After the protrusion 10 is inserted into the rubber body 1, the sliding friction between the support body 2 and the rubber body 1 can be increased, and the phenomenon of detachment of the support body 2 and the rubber body 1 when receiving external stress can be avoided.

[0037] Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com