Lead framework used for battery module, lead framework assembly and battery module

A technology of lead frame and battery module, applied in the direction of battery components, battery circuit devices, batteries, etc., can solve the problems of insufficient power, difficulties in electric vehicles, high battery cost, etc., and achieve reasonable layout, large installation space, and improved space The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

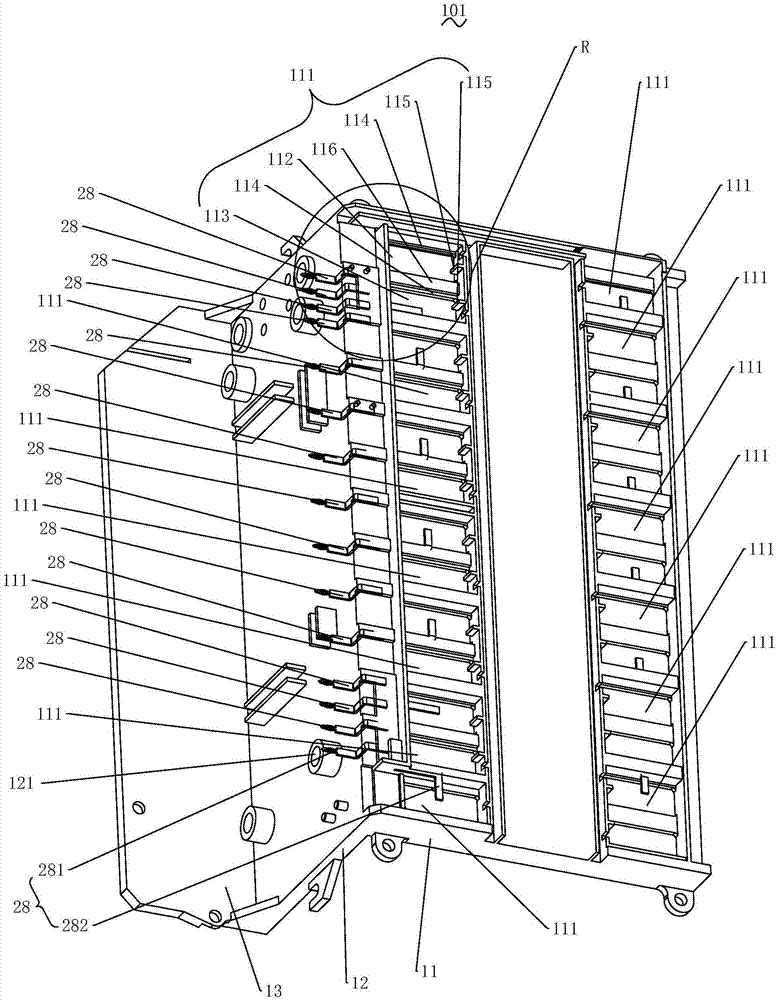

[0055] See figure 1 , Which is a schematic structural diagram of a lead frame 101 for a battery module provided by the present invention. The lead frame 101 for the battery module includes a frame body 11, a setting portion 12 and a plurality of connection terminals 28. The frame body 11 is used to install the following connecting piece 20.

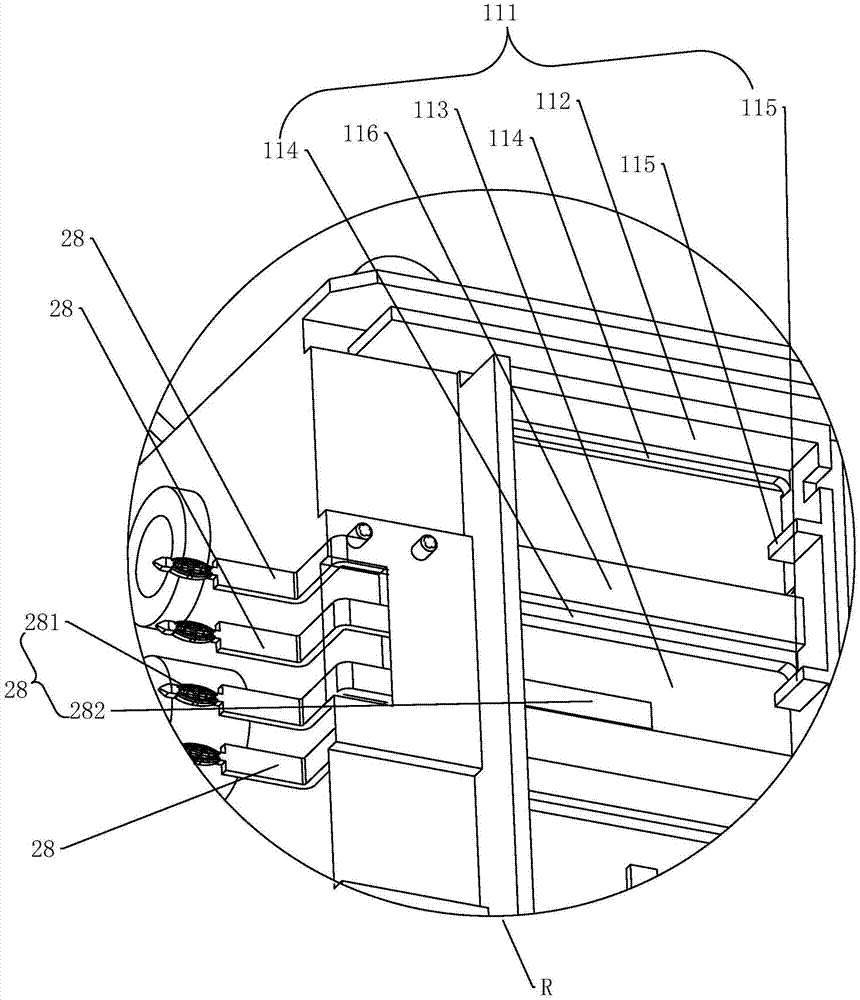

[0056] Please refer to figure 2 , The frame body 11 has a mounting portion 111. The mounting portion 111 is used for mounting the following connecting piece 20. The overall shape and size of the frame body 11 are selected according to the installation environment. In this embodiment, in order to adapt to a relatively narrow installation environment, the frame body 11 is arranged in a rectangular parallelepiped plate shape. The mounting portion 111 only needs to be able to mount the connecting member 20 described below.

[0057] In this embodiment, in order to facilitate installation and removal, the installation portion 111 is provided wi...

Embodiment 2

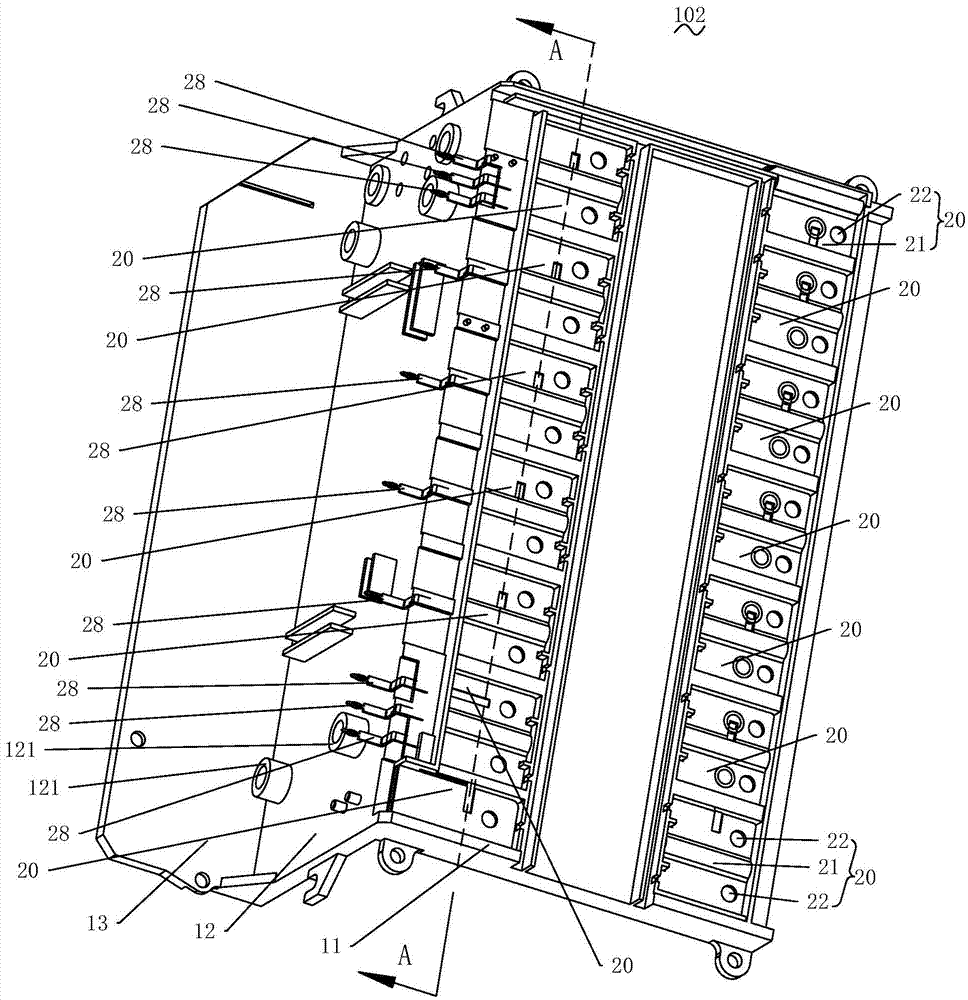

[0070] Please refer to Figure 3 to Figure 7 The present invention also provides a schematic structural diagram of the lead frame assembly 102. The lead frame assembly 102 includes the lead frame 101 for the battery module and the connector 20 described above. The connector 20 is provided on the mounting portion 111 of the frame body 11 of the lead frame 101 for the battery module.

[0071] In this embodiment, the connecting member 20 is accommodated in the accommodating portion 112 of the mounting portion 111 and is arranged on a step 114 on the inner side wall of the accommodating portion 112. The number and specific shape of the connecting members 20 are selected according to the connection requirements. In this embodiment, the number and specific shape of the connecting members 20 only need to meet the requirements for connecting with the electrodes of the battery described below. Specifically, the number of the connecting members 20 in the second embodiment matches the num...

Embodiment 3

[0076] Please refer to Figure 8 to Figure 10 The difference between this embodiment of the lead frame assembly 102 and the foregoing embodiments is that: in order to facilitate the realization of corresponding electrical performance, the lead frame assembly 102 further includes a circuit board 30 and electronic components 66. The electronic component 66 is electrically connected to the circuit board 30. The electronic component 66 may be a relay.

[0077] The circuit board 30 may also be referred to as a PCB (Printed Circuit Board, printed circuit board). The connecting member 20 further includes a connecting portion 22. The connecting portion 22 is used to connect with the following battery module. The connecting portion 22 and the battery module only need to be electrically connected, such as contact. In this embodiment, in order to obtain a stable connection performance, the connecting portion 22 is a through hole. After the electrode of the battery module extends into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com