Insulation puncturing wire clamp and method for connecting cable by employing same

A technology of insulation puncture and clamping method, which is applied in the direction of needle tip/slotted plate contact, clamping/spring connection, connection, etc. used to penetrate insulation wire/cable core wire, which can solve the problem of difficult operation and cutting wire Cable conductors, high operator requirements, etc., to achieve the effect of a wide range of wire diameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

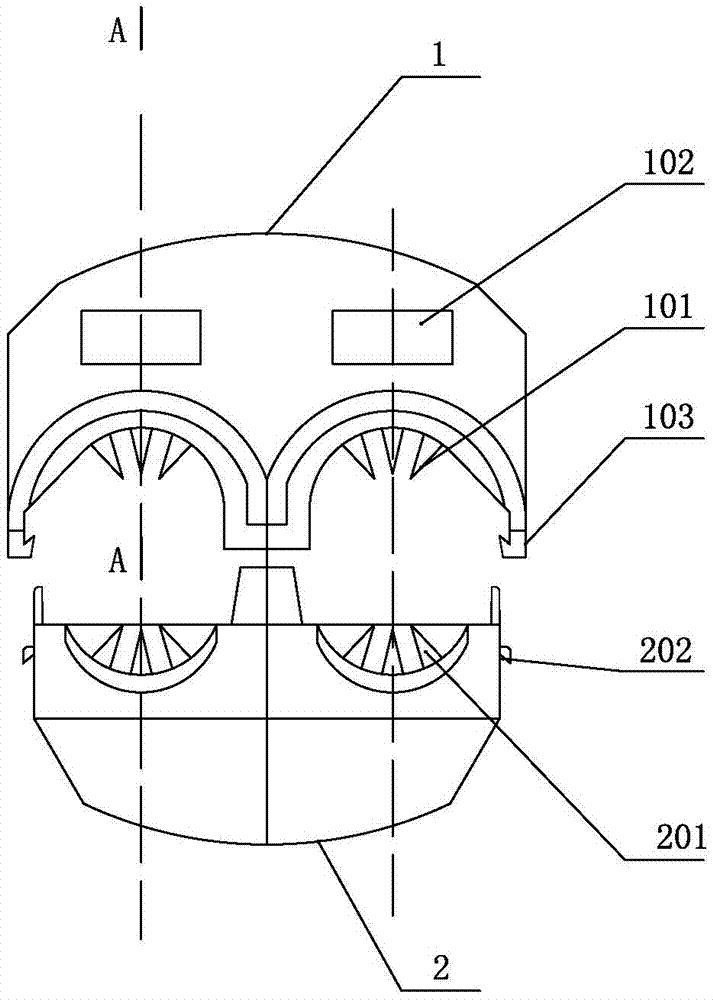

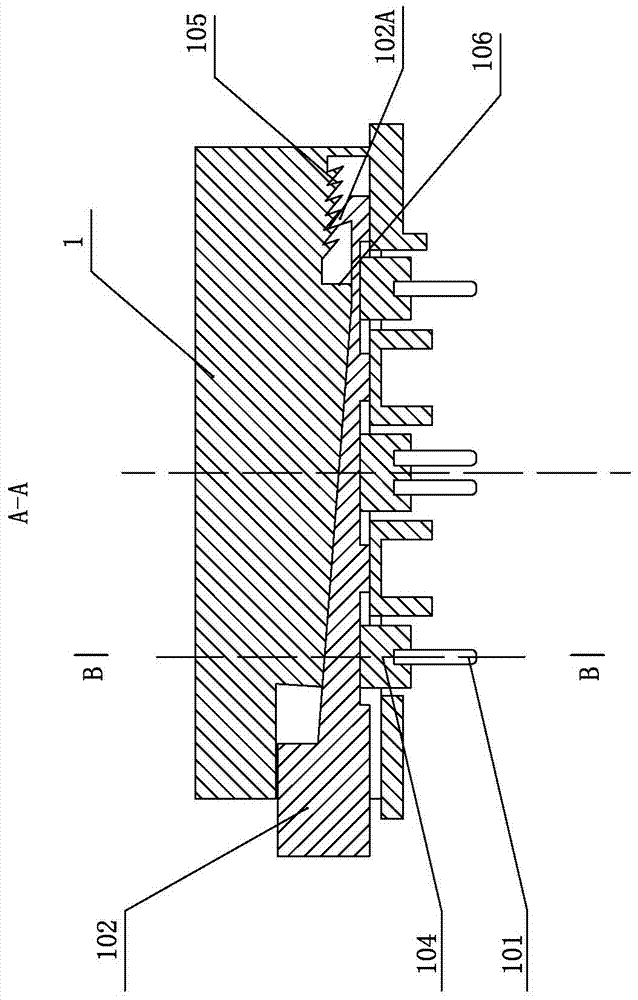

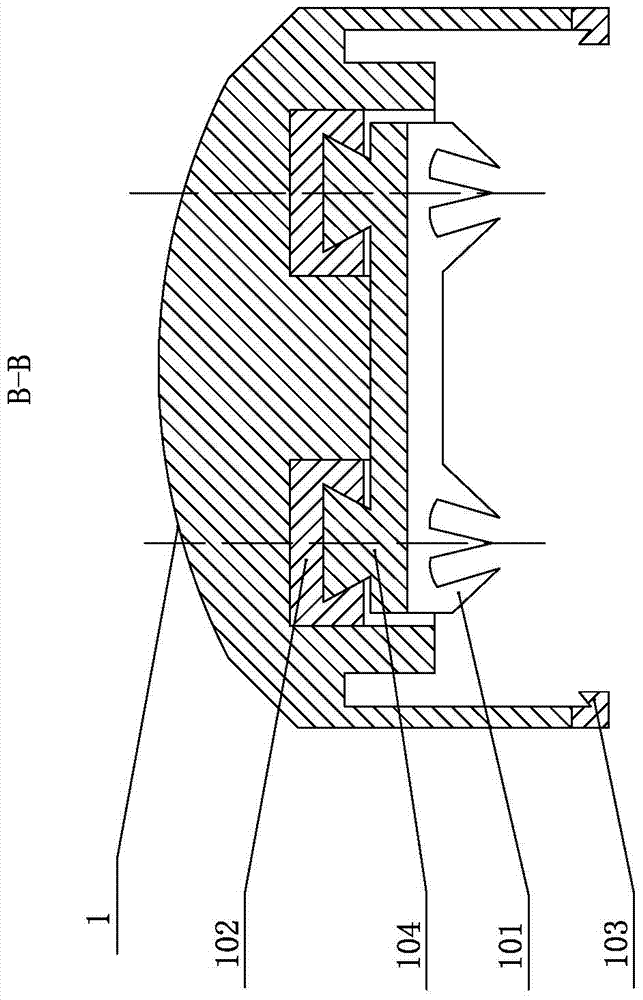

[0020] like figure 1 — image 3 As shown, it is the insulating piercing wire clip of the present invention, which includes an upper casing 1 and a lower casing 2 that are matched and docked. There is an upper piercing blade 101 that runs through the two upper half grooves and an elastic pad that matches the shape of the lower side of the upper casing 1 and facilitates the passage of the upper piercing blade 101; the upper side of the lower casing 2 is provided with a lower half corresponding to the upper half groove. Groove, the position corresponding to the upper puncture blade 101 in the lower casing is fixedly provided with the lower puncture blade 201 and matches with the shape of the upper side of the lower casing 2 and facilitates the lower puncture blade to pass through the elastic pad; the upper casing 2 and the lower casing 3 cooperate The outer sides of the butt joint are equipped with elastic buckles; the elastic buckles include elastic hooks 103 arranged on the lo...

Embodiment 2

[0024] like Figure 4 As shown, the clamping method for connecting insulated cables by using the above-mentioned insulation puncture clamp includes the following steps: 1) filling the arc-shaped half grooves of the upper casing 1 and the lower casing 2 with waterproof silicone and elastic pads respectively, Then put the main cable and the branch cable into the lower half groove of the lower casing 2 respectively and align the cables with the lower piercing blade 201 in the lower half groove, and then match the upper casing 1 with the lower casing 2 Docking and pre-tightening through the elastic buckle. At this time, the wedge-shaped extrusion block 102 in the upper housing is at the initial position, that is, the barb is at the inner step;

[0025]2) Clamp the upper housing 1 with the special clamping tool 3, push the wedge-shaped extrusion block 102 to slide inside the upper housing 1, and at the same time, the wedge-shaped extrusion block 102 pushes the upper puncture blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com