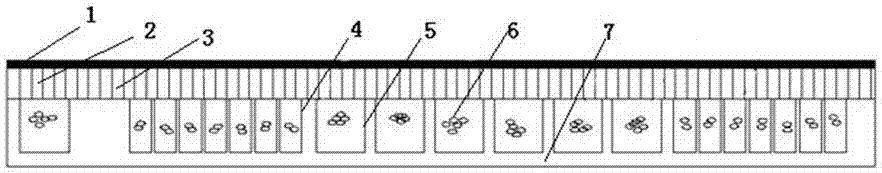

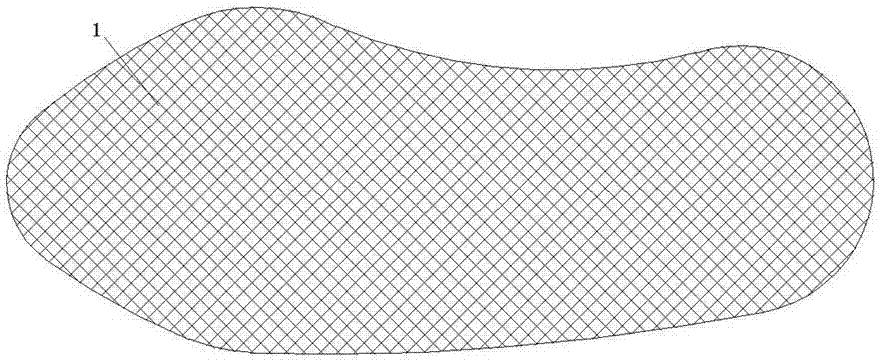

Foot blister resistant shoe pad for high strength load bearing march and preparation method of foot blister resistant shoe pad

A high-strength, insole technology, used in insoles, footwear, applications, etc., can solve problems such as poor durability and comfort, damage to image, and unsightly sanitary napkins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

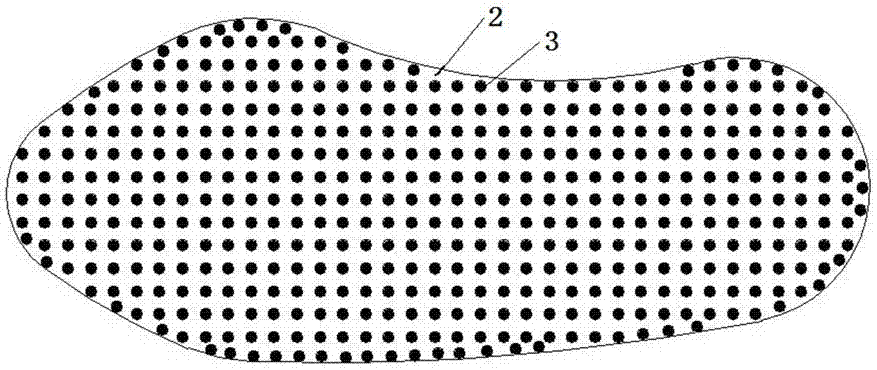

Image

Examples

Embodiment 1

[0034] 1) Add 100 g of EVA with a vinyl acetate content of 10 wt%, 5 g of azodicarbonamide and 0.1 g of dicumyl peroxide into a high-speed mixer, mix at room temperature for 3 min, and mix the mixture by banburying The mixed material was obtained by kneading with a machine, the kneading temperature was 100 ℃, and the kneading time was 30 min;

[0035] 2) Put the mixed material prepared in step 1) into the tablet machine to process into the required insole body embryo, put the body embryo into the molding mold for hot-press foam molding, the molding temperature is 160 ℃, and the molding pressure is 20 MPa , the molding time is 20 min, and after cooling and shaping, the required EVA foam material of the breathable and sweat-permeable layer of the insole and the cushioning and water-absorbing layer with blind holes is obtained;

[0036] The blind holes are molded on the water-absorbing layer by hot-pressing molds. The blind holes include large blind holes and small blind holes. ...

Embodiment 2

[0046] 1) Add 100 g of EVA with a vinyl acetate content of 22 wt%, 20 g of 4,4'-oxobisbenzenesulfonyl hydrazide and 0.5 g of bis-tert-butylperoxydicumylbenzene into a high-speed mixer, and Mix at room temperature for 10 minutes, and use an internal mixer to mix the mixture to obtain a mixed material. The mixing temperature is 140 ° C, and the mixing time is 10 minutes;

[0047] 2) Put the mixed material prepared in step 1) into the tablet machine to process into the required insole body embryo, put the body embryo into the molding mold for hot-press foam molding, the molding temperature is 180 ℃, and the molding pressure is 15 MPa , the molding time is 10 min, and after cooling and shaping, the required EVA foam material of the breathable and sweat-permeable layer of the insole and the cushioning and water-absorbing layer with blind holes is obtained;

[0048] The blind holes are molded on the water-absorbing layer by hot-pressing molds. The blind holes include large blind hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com