Latex vamps, shoes and preparation method thereof

A shoe upper and latex technology, applied in the field of latex shoe uppers, shoes and their preparation, can solve the problems of not being durable, the feeling of contact needs to be strengthened, the feet sweating, etc., and achieve mildew and antibacterial comfort, long service life, Strong sweat absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of latex shoe upper comprises the following steps:

[0033] (1) Prepare foam latex layer:

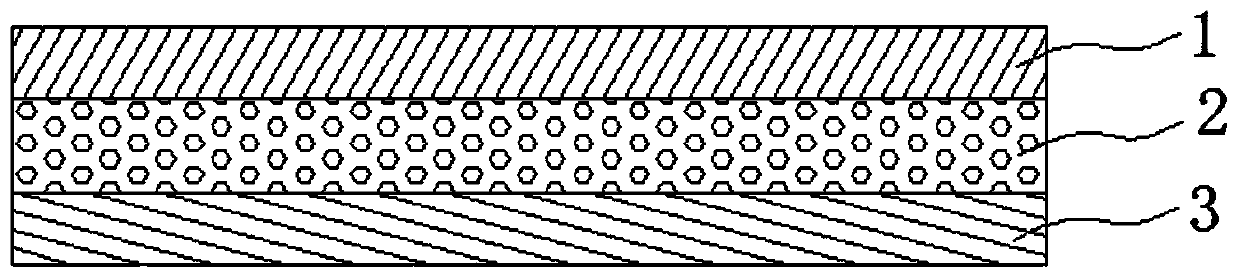

[0034] Put 60-75% of natural latex, 20-35% of styrene-butadiene rubber and 3-8% of additives into the mixing equipment in proportion to mix, stir well, and put the well-stirred latex mixture into the foaming equipment Foaming in the medium, then pour the foamed latex mixture onto the conveyor belt, and adjust the thickness of the latex mixture, then transport it to the oven for drying, add sulfur and vulcanize, and obtain the preset thickness after the second adjustment of the thickness Sheet foam latex layer;

[0035] (2) Upper molding:

[0036] The foamed latex layer is placed between the outer fabric layer and the inner fabric layer, and the foamed latex layer, the outer fabric layer and the inner fabric layer are hot-pressed and connected together by a hot pressing device to form a latex shoe upper.

[0037] Wherein, the drying temperature may prefer...

Embodiment 1

[0040] Embodiment 1 of the present invention provides a kind of latex vamp, comprises outer fabric layer, foamed latex layer and inner fabric layer, and described foamed latex layer is formed by foaming of following raw material: natural latex 65%; SBR 32%; Auxiliary 3%.

[0041] The preparation method of latex shoe upper comprises the following steps:

[0042] (1) Prepare the foamed latex layer: 65% of natural latex, 32% of styrene-butadiene rubber and 3% of additives are put into the stirring equipment in proportion to mix, stir evenly, put the well-stirred latex mixture into Foaming is carried out in the foaming equipment, and then the foamed latex mixture is poured onto the conveyor belt, and the thickness of the latex mixture is adjusted, and then it is transported to the oven for drying, vulcanized with sulfur, and after the second thickness adjustment, the obtained Sheet-shaped foam latex layer with preset thickness;

[0043] (2) Vamp forming: the foam latex layer is ...

Embodiment 2

[0047] Embodiment 2 of the present invention provides a kind of latex vamp, comprises outer fabric layer, foamed latex layer and inner fabric layer, and described foamed latex layer is formed by foaming of following raw materials: natural latex 67.5%; SBR 27.5%; auxiliary agent 5%.

[0048] The preparation method of latex shoe upper comprises the following steps:

[0049] (1) Prepare the foamed latex layer: 67.5% of natural latex, 27.5% of styrene-butadiene rubber and 5% of additives are put into the mixing equipment in proportion to mix, stir evenly, and put the well-stirred latex mixture into the Foaming is carried out in the foaming equipment, and then the foamed latex mixture is poured onto the conveyor belt, and the thickness of the latex mixture is adjusted, and then it is transported to the oven for drying, and after sulfuration and vulcanization, the thickness is adjusted twice to obtain the desired Set the thickness of the lamellar foam latex layer;

[0050] (2) Vam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com