Chemical experiment distilling apparatus

A distillation device and a technology for chemical experiments, applied in the field of chemical experiments, can solve problems such as unfavorable physical and mental health of students, pollute the teaching environment, unsafe operation, etc., and achieve the effects of uniform heating, avoiding pollution and shortening distillation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

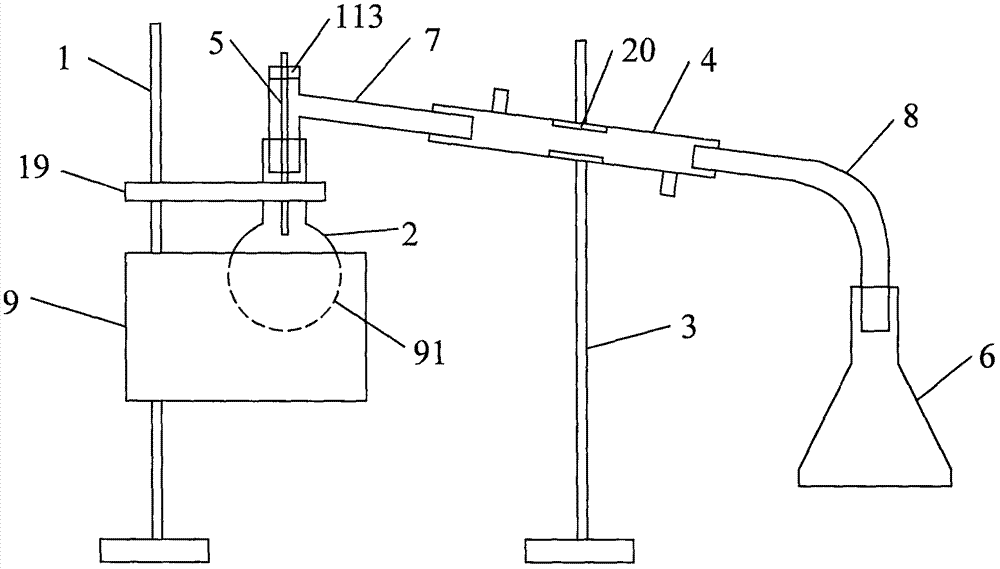

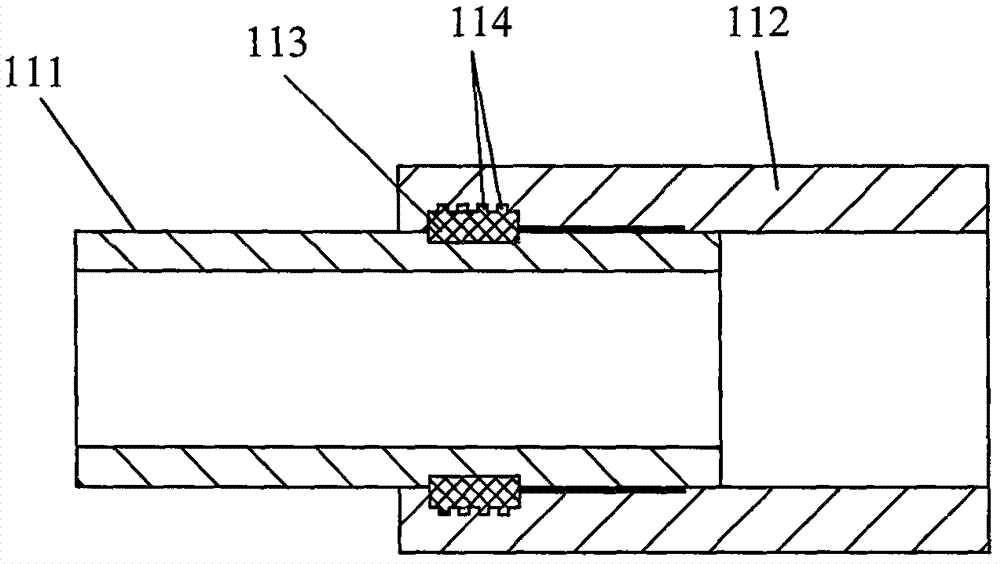

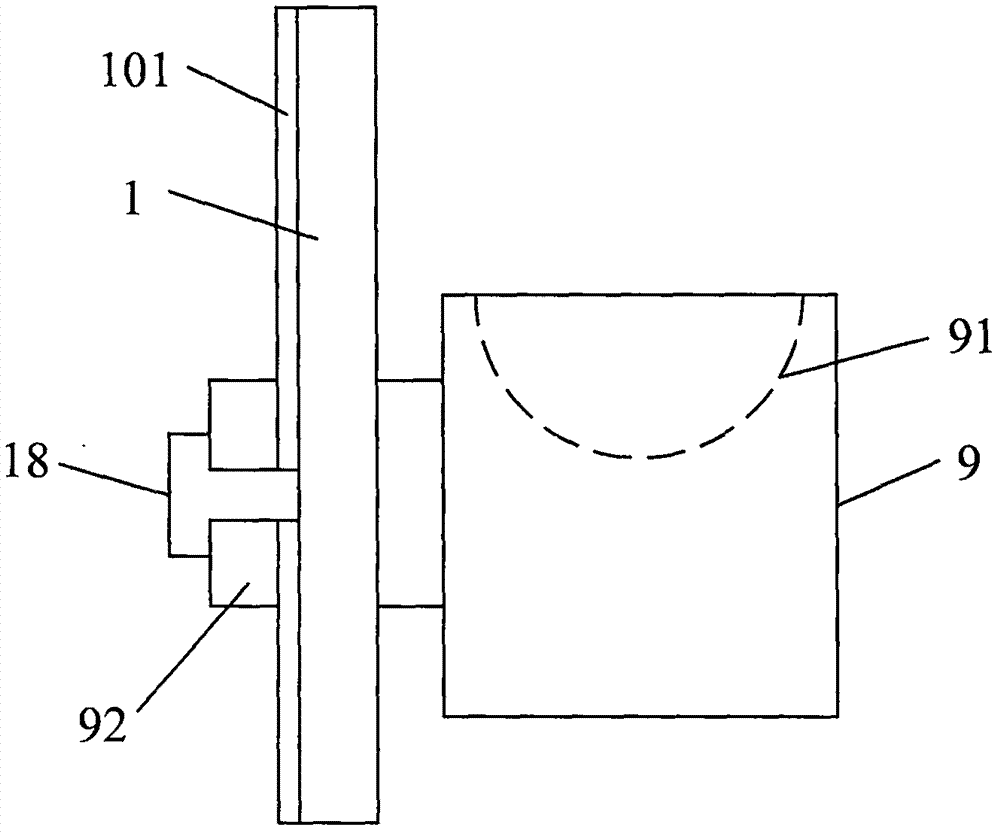

[0053] Such as figure 1 As shown, the application provides a kind of chemical experiment distillation device, comprises the flask 2 that is installed on the first support 1, the condensation tube 4 that is installed on the second support 3, thermometer 5, contact bottle 6, flask 2 and condensation The gas delivery pipe 7 connected with the pipe 4, the liquid delivery pipe 8 connected with the condensation pipe 4 and the liquid contact bottle 6, and the heater 9 installed on the first support 1 and directly below the flask 2, in the heater 9 There is a heating chamber 91 with an opening facing the flask 2, and an electric heating wire arranged on the inner peripheral side of the heating chamber 91, so the electric heating wire is fixedly installed in the insulating housing of the heater 9, and the heating chamber 91 is connected to the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com