Supercritical extraction kettle capable of achieving automatic loading and unloading

An automatic loading and unloading, supercritical technology, applied in the direction of solvent extraction, solid solvent extraction, chemical instruments and methods, etc., can solve the problems affecting the quality and efficiency of extraction, inconvenient loading and unloading of extraction kettles, and unreliable sealing of material cylinders, etc., to achieve The structure is reasonable, the lifting is convenient and fast, and the time is shortened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

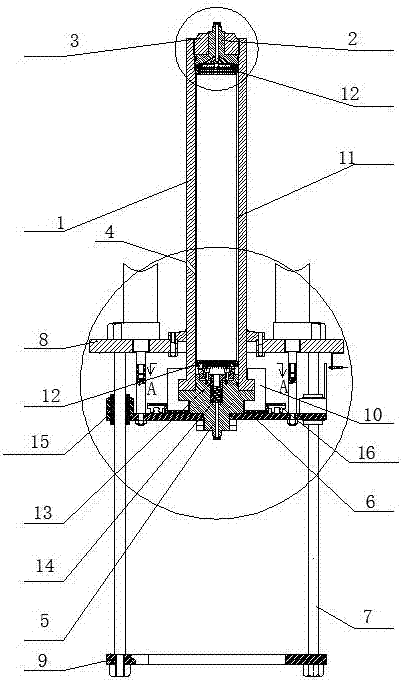

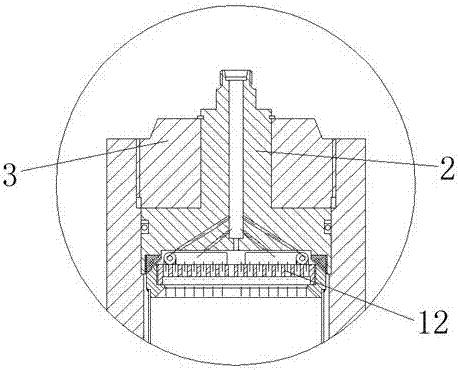

[0028] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

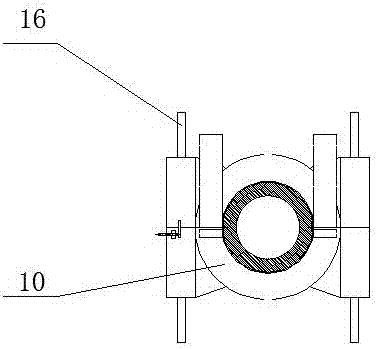

[0029] As shown in the figure, an automatic loading and unloading supercritical extraction kettle of the present invention includes a main body part 1, a material cylinder part, a lifting part and an opening and closing clamp part, wherein the material cylinder part is located in the inner cavity of the main body part 1, and the lifting part is located in Below the main part 1, the opening and closing hoop part is located at the junction of the main part 1 and the lifting part, wherein the main part 1 is a cylindrical cylinder, and the upper opening of the main part 1 is provided with an upper plug 2 and a pressure cap 3 in turn, and the upper The center of the upper end surface of the plug 2 is provided with an outlet hole, and the lower end surface of the upper plug 2 has a plurality of small holes, and each small hole is indepen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com