Coaxial positioning jig for folded edge pipeline

A coaxial positioning and pipeline technology, which is applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problem of poor coaxiality and verticality between the pipeline 11 and the flange 12, and the nozzle cannot be round and cannot reach Product standards and other issues to achieve the effect of increasing torque, ensuring verticality, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with specific embodiments.

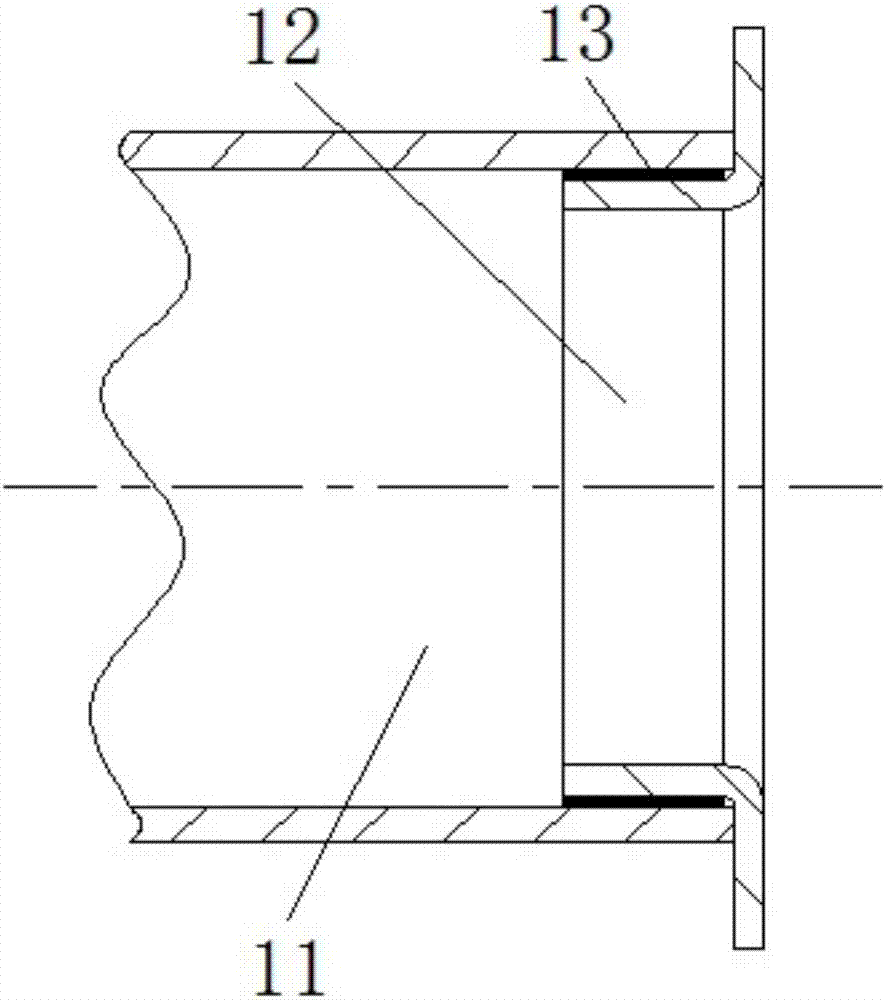

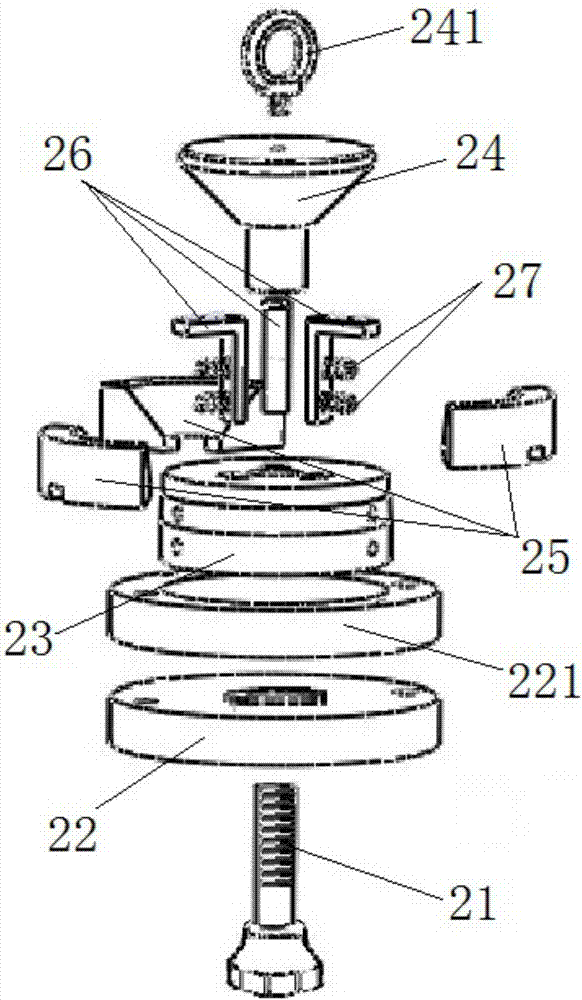

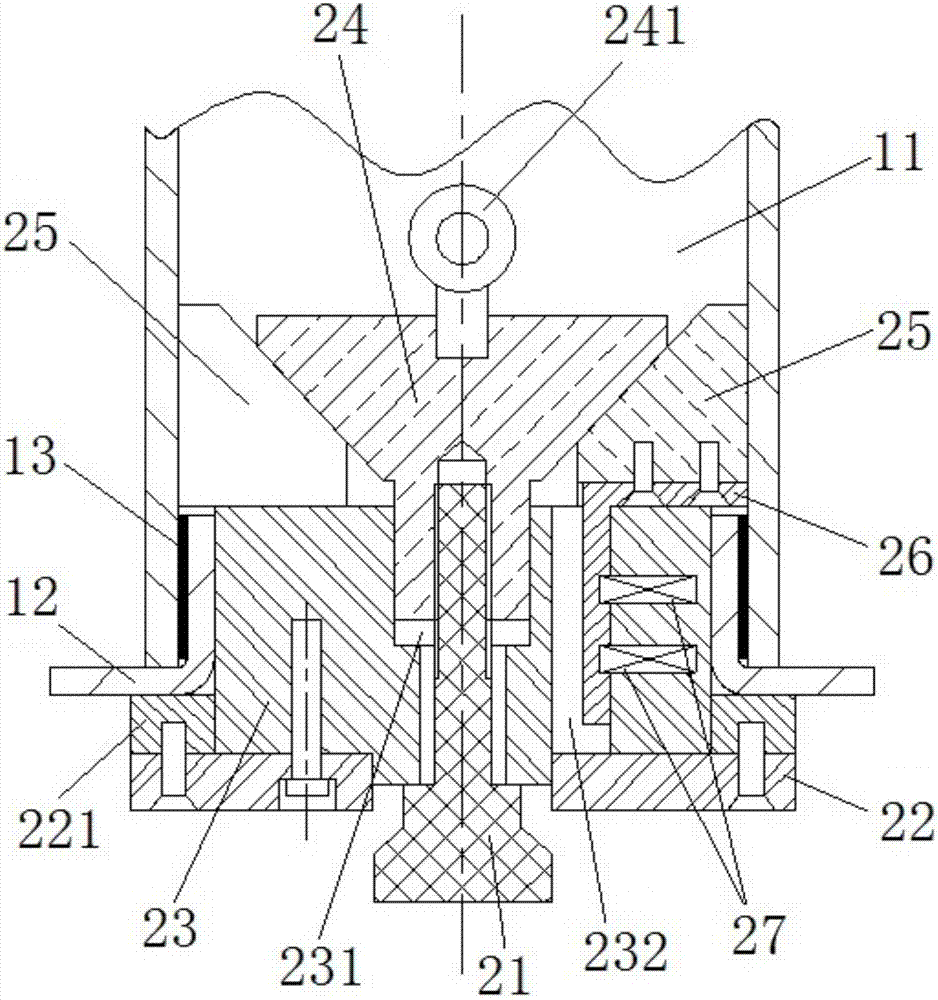

[0042] Such as Figure 1 to Figure 3 As shown, the present invention is a coaxial positioning jig for flanging pipes, which includes an expansion body 24 with a cone and a cylinder and an adjusting bolt 21 inserted from the rear of the cylinder. The expansion body 24 and the adjustment bolt 21 are sleeved There is a sleeve 23, the sleeve 23 is provided with a cavity 231 for the cylinder to penetrate and a number of square holes 233 uniformly distributed around the cavity 231, and the expansion body 24 and the sleeve 23 are clamped with a corresponding number of square holes 233 Expansion blocks 25, each expansion block 25 has a conical surface that matches the cone, and a right-angle movable frame 26 is fixedly connected to the expansion block 25. One side of the movable frame 26 is fixed with the expansion block 25, and the other side penetrates the square hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com