Upper sill door head assembly equipment for elevator

An assembly equipment and the technology of the gate head, which is applied in the field of elevators, can solve the problems that the gap between the track and the roller is too large or too small, which affects the service life and safety performance of the upper gate head, and achieves the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

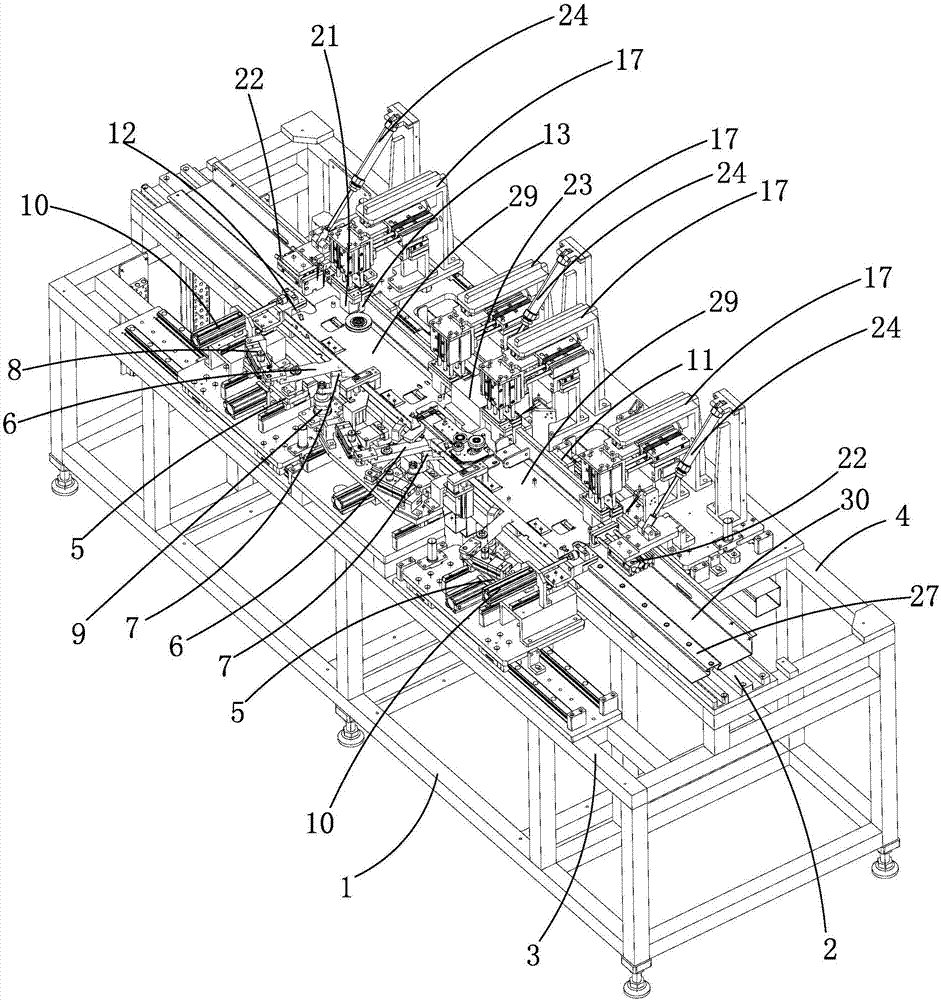

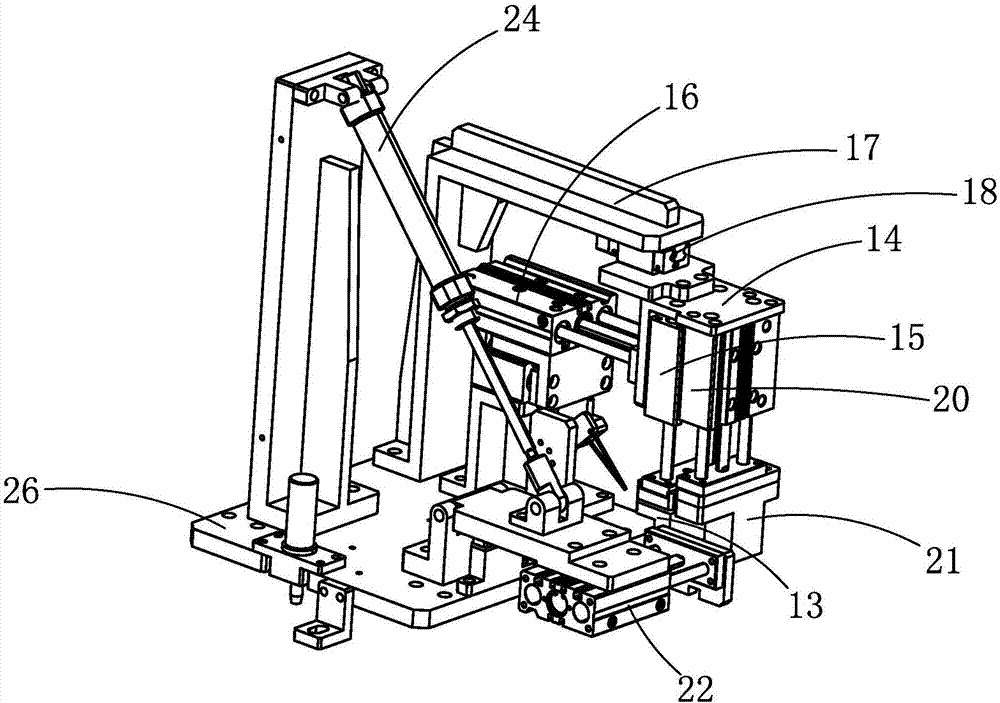

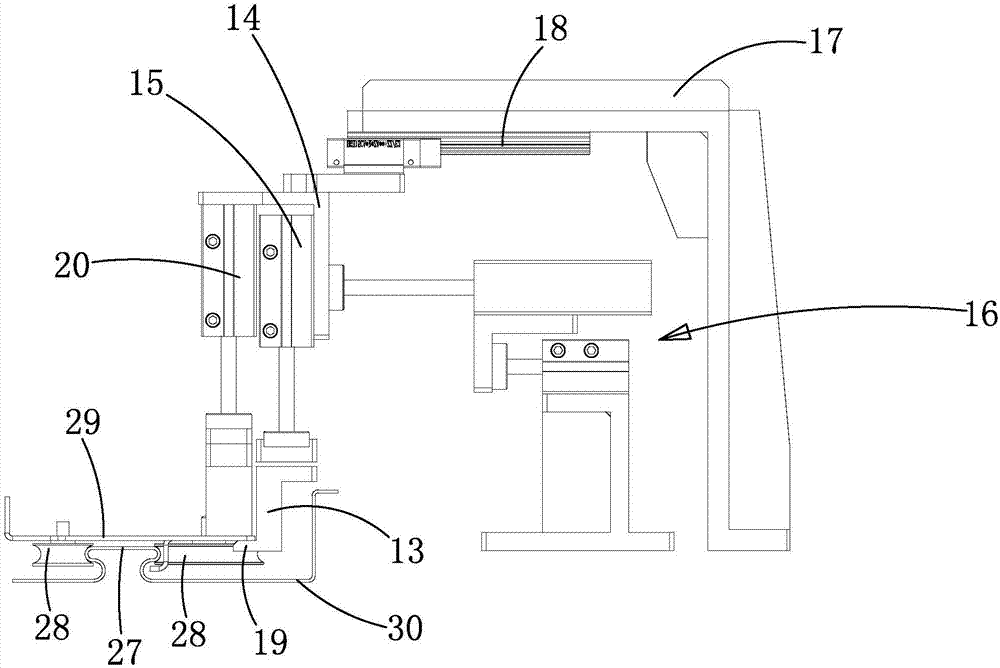

[0021] Such as figure 1 The shown assembly equipment for the upper gate head of an elevator is composed of a frame 1 and an installation platform 2 located on the top surface of the frame 1. The edge 4 is provided with a first positioning structure, a second positioning structure and a third positioning structure for respectively positioning the upper rocker 30, the door hanging plate 29 and the roller 28, so that the roller 28 is positioned between the track 27 of the upper rocker 30. On the installation station with equal height and 0.2mm-0.5mm longitudinal gap reserved.

[0022] When in use, the first positioning structure is used to fix the upper sill 30, the second positioning structure is used to fix the door hanging plate 29, and the third positioning structure is used to fix the roller 28, so that the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com