Single-track transport machine for mountain internal combustion engine

An internal combustion engine and single track technology, applied in the direction of transportation and packaging, conveyors, containers to prevent mechanical damage, etc., can solve the problems of high cost of transportation roads, reduced transportation quality, bumps and collisions of crops in transportation boxes, etc., to improve transportation efficiency and Transport quality, improve service life, reduce the effect of poor operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

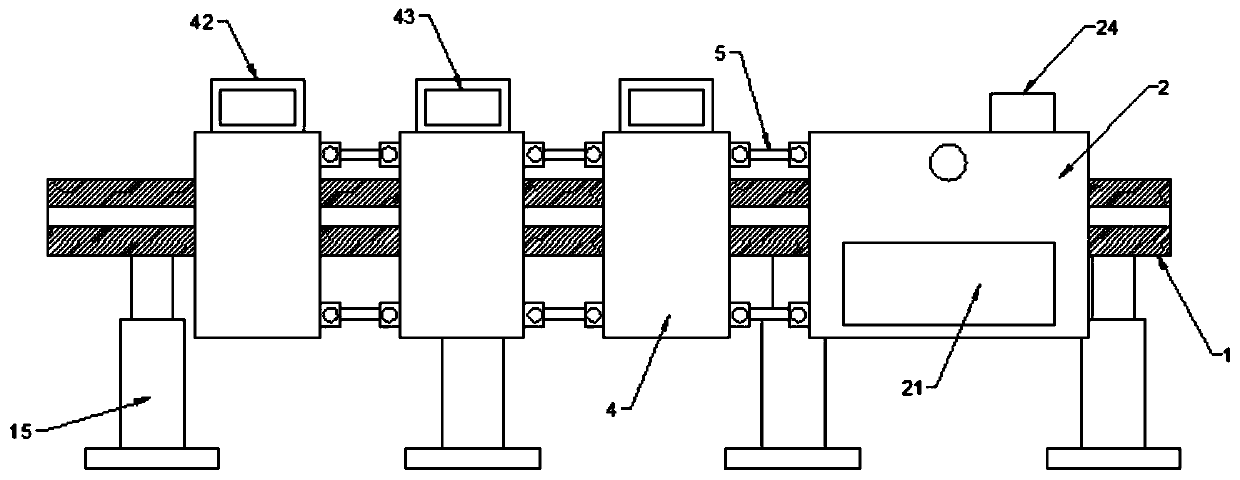

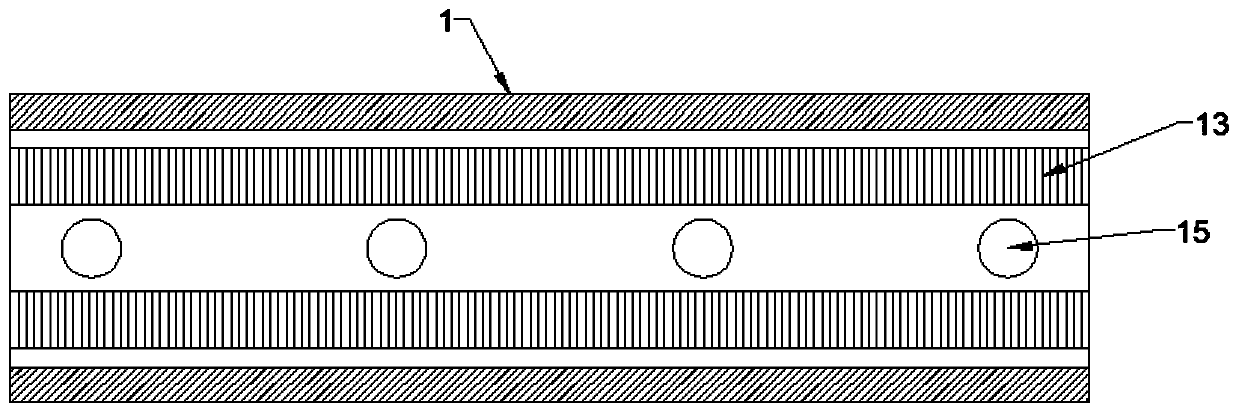

[0025] see Figure 1~5 , in an embodiment of the present invention, a mountainous internal combustion engine single-track transporter includes a transport track 1, a transport nose 2, an internal combustion engine 3 and a storage box 42, and the transport track 1 is supported and installed on a mountain area by a height-adjustable movable support frame device. Among them, the carriage on the transport track 1 is provided with a transport nose 2 and a plurality of transport slides 4, the transport nose 2 is connected to a plurality of transport slides 4 through a connecting piece 5, and the transport nose 2 is provided with a The drive mechanism that drives the transport head 2 to move forward on the transport track 1, the transport head 2 is equipped with a console 24 for controlling the opening and closing of the drive mechanism, and the transport slide 4 is provided with a storage box 42 for loading items The transport head 2 and the transport slide 4 are slidingly clamped o...

Embodiment 2

[0032] The difference between this embodiment and embodiment 1 is:

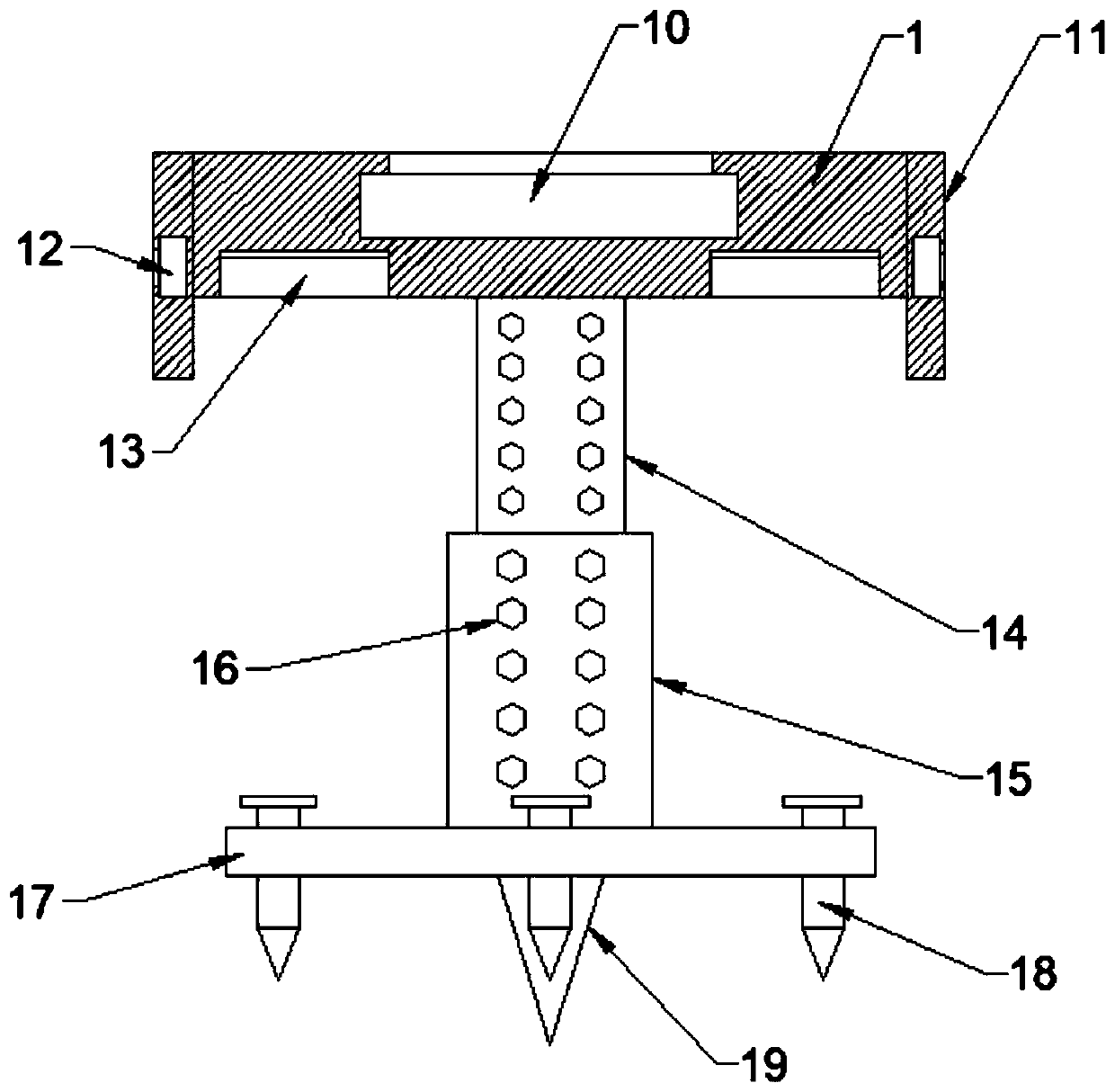

[0033] The movable support device includes an adjusting rod 14, a support tube 15 and a chassis 17, the adjusting rod 14 is slided and sleeved in the supporting tube 15, and a plurality of holes for screw fixing are provided on the adjusting rod 14 and the supporting tube 15. Adjust the screw hole 16, the bottom of the support tube 15 is fixed with a circular chassis 17, and the upper circumference of the chassis 17 is provided with a plurality of pointed downward chassis fixing pins 18, the center of the bottom surface of the support tube 15 Place is fixed with the support main pin 19 that point is downward.

[0034] The connector 5 includes a plurality of side-by-side fixed connecting bracket plates 51 fixed on the transport head 2 and the transport slide 4 and the transport slide 4 and the adjacent transport slide 4, and the connecting bracket plates 51 rotate The support plate rotating shaft 52 is fixed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com