Four-axis wire drawing machine

A wire machine and shaft pulling technology, which is applied in the direction of grinding frame, grinding machine parts, grinding machines, etc., can solve the problems that the lines cannot be connected, reduce labor intensity and labor cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

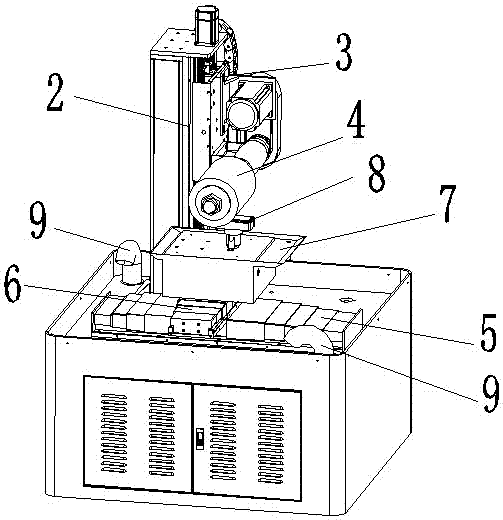

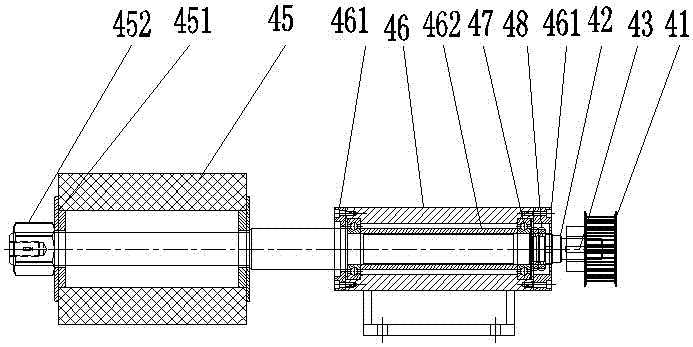

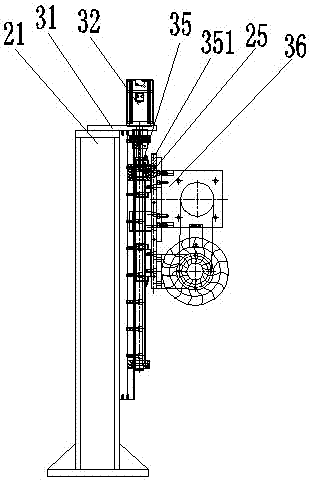

[0023] In this example, refer to Figure 1 to Figure 10 As shown, a four-axis wire drawing machine of the present invention includes a frame 1, a column mechanism 2 is arranged on the top surface of the frame 1, a Z-axis elevating mechanism 3 is arranged on one side of the column mechanism 2, and a Z-axis elevating mechanism 3 One side of the wire drawing wheel mechanism 4 is provided with; The wire drawing wheel mechanism 4 includes a synchronous pulley 41, which is connected with the synchronous pulley 41 and is provided with a main shaft 42, and the center of one end of the main shaft 42 is provided with a flat key 43, and the other side of the main shaft 42 One end is provided with a wire drawing wheel 45, and a machine head 46 is arranged between the synchronous pulley 41 and the wire drawing wheel 45. The front and rear ends of the machine head 46 are respectively provided with flanges 461, and a spacer 462 is arranged in the machine head 46, and the spacer 462 The front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com