Medicine bottle filling assembly with production counting function

A production capacity and medicine bottle technology, applied in packaging, threaded bottle caps, bottle filling, etc., can solve the problems of low efficiency and unsuitable for large-scale automatic assembly and production, and achieve the effect of high efficiency, compact structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

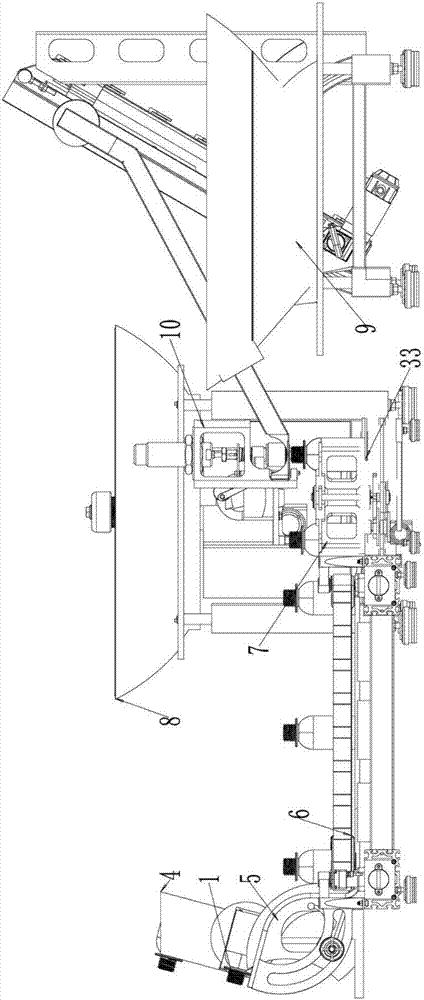

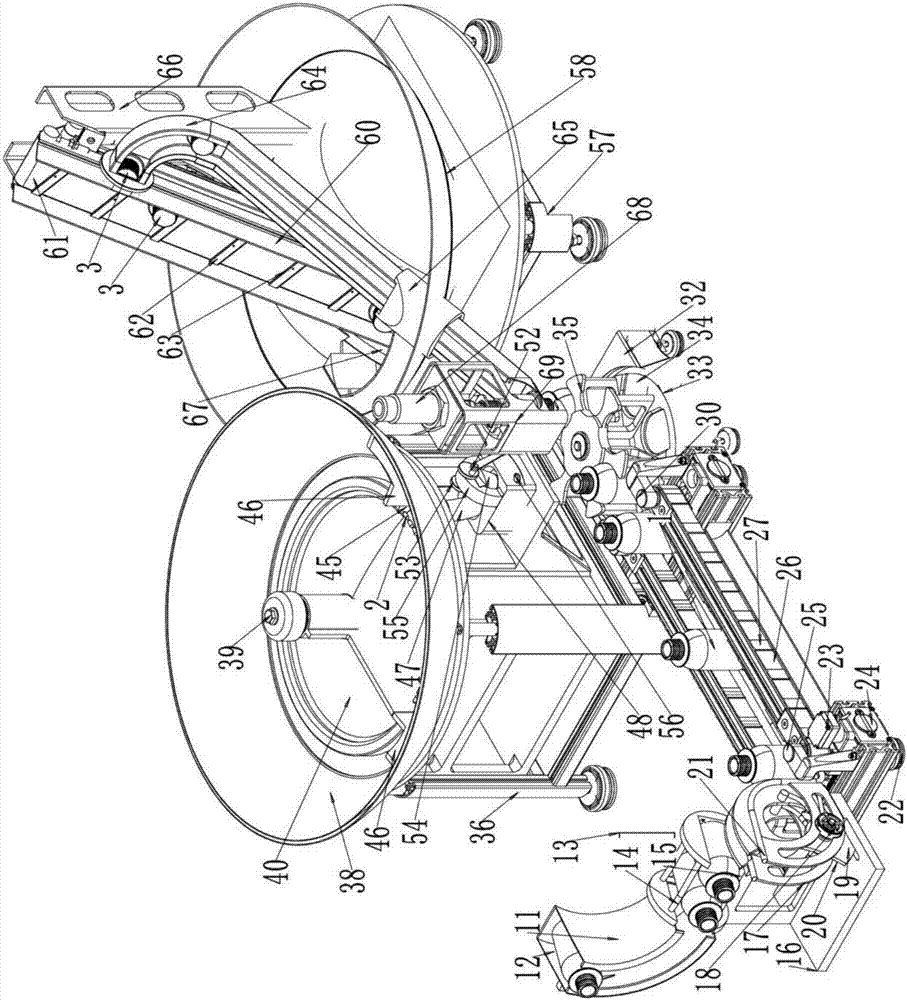

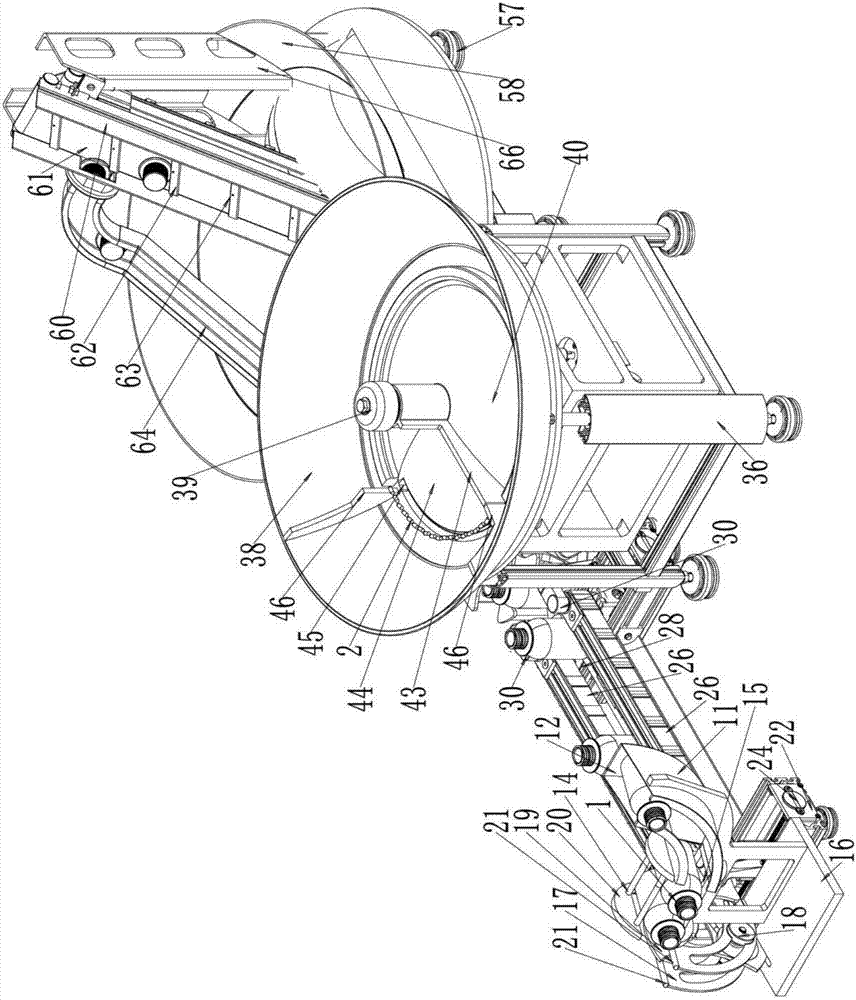

[0033] Such as Figure 1-15 As shown, the medicine bottle filling assembly with the production volume counting function of this embodiment includes a feeding device 4, an overturning device 5, a conveying device 6, an indexing device 7, a feeding device 8, a cap feeding device 9, a sealing device Cover device 10, discharge synchronous suspension turntable 85 and discharge conveying device 86;

[0034] The indexing device 7 includes four stations connected in sequence: the filling station for clamping the vertically placed bottle body 1, the filling station for filling the bottle body 1 with the capsule 2, and the filling station for the filled capsule 2. The bottle body 1 carries out the capping station for installing the bottle cap 3 and the discharging station for transferring the bottle body 1 after the bottle cap 3 is installed;

[0035] The feeding device 4 transfers the horizontally placed bottle 1 to the overturning device 5, and the overturning device 5 rotates the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com