Glass stacking device

A glass code and glass technology, applied in the direction of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of inconvenient portability, large shelf body, troublesome handling, etc., and achieve the effect of easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below.

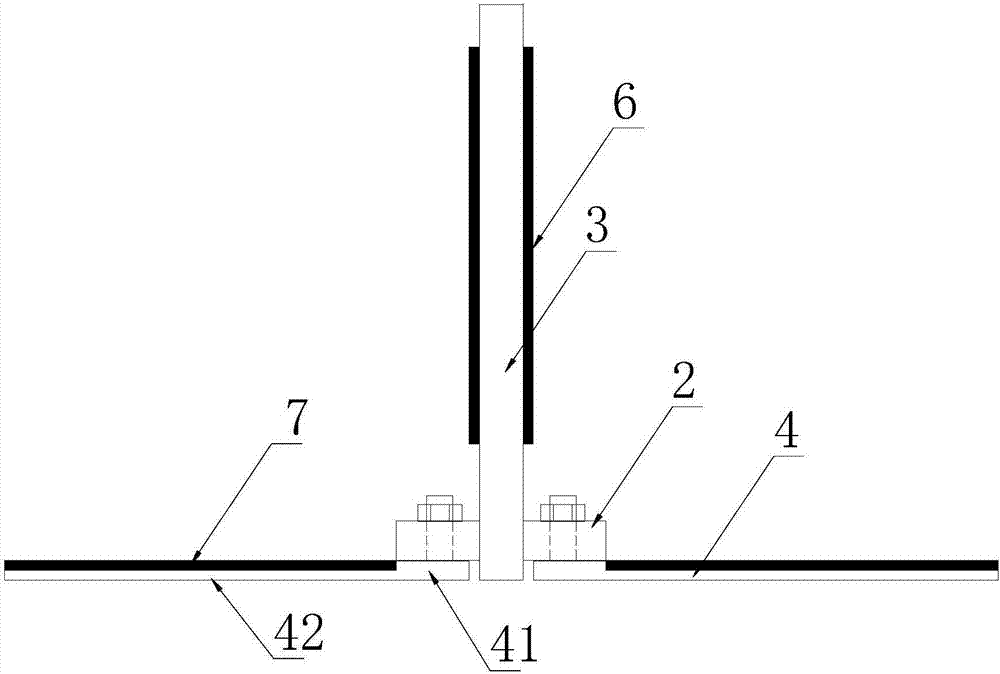

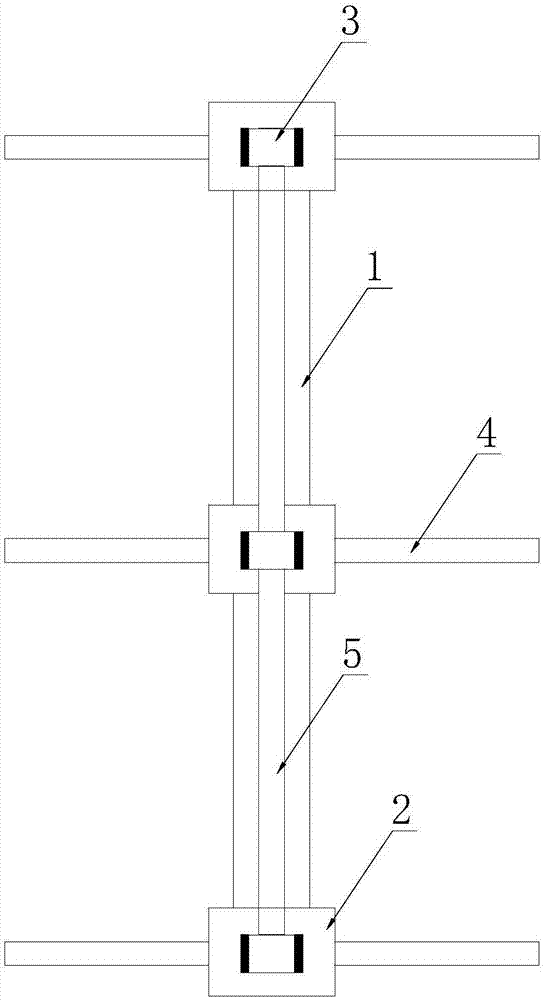

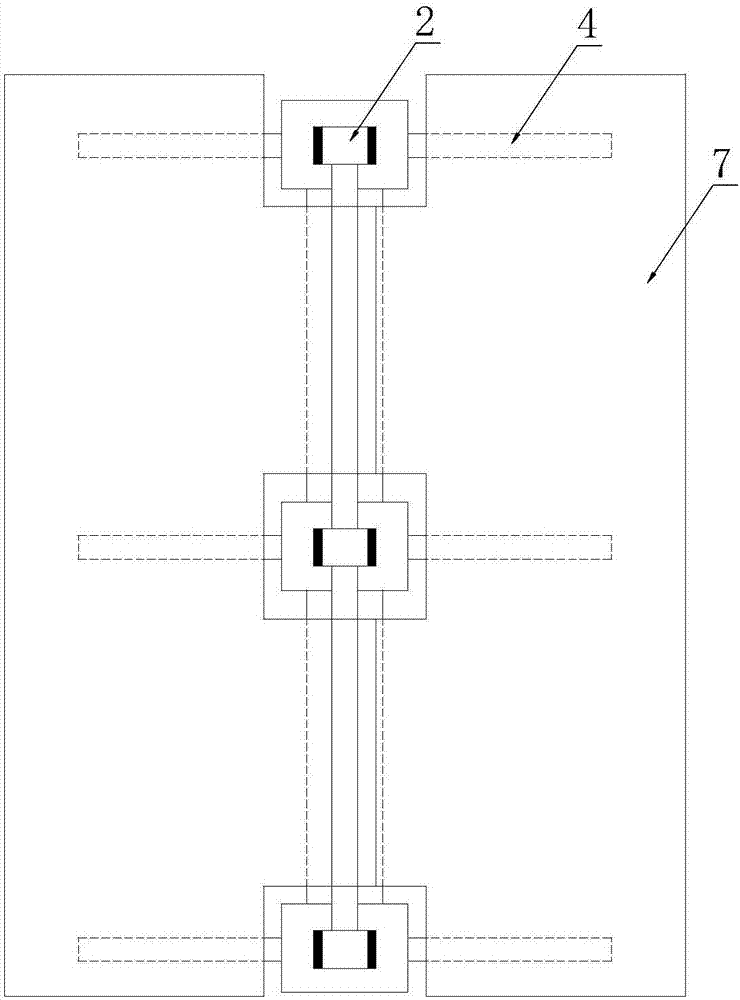

[0018] The glass stacking device disclosed in the present invention includes a bottom plate 1, a base 2, a column 3, a supporting plate 4, and a cross bar 5. The number of the bases 2 is at least two, and the bases 2 are connected to each other through the bottom plate 1. The uprights 3 are arranged on the base 2 and the upper parts of the uprights 3 are connected to each other by a cross bar 5. The supporting plate 4 is arranged below the base 2, and the supporting plate 4 is hinged to the base 2 and can be rotated along a plane perpendicular to the upright 3 A first flexible anti-skid pad 6 is fixed on both sides of the column 3, and a second flexible anti-skid pad 7 is provided on the support plate 4.

[0019] When in use, turn the pallet 4 out so that it is roughly perpendicular to the bottom plate 1. The structural shape formed by the pallet 4 and the column 3 can be either L-shaped or inverted T-shaped. If the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com