Variable diameter rotary body fabric needling molding equipment

A molding equipment and rotary body technology, applied in acupuncture machines, non-woven fabrics, textiles and papermaking, etc., can solve the problems of product layering and uneven layer density, achieve convenient operation, ensure performance, and control acupuncture products effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

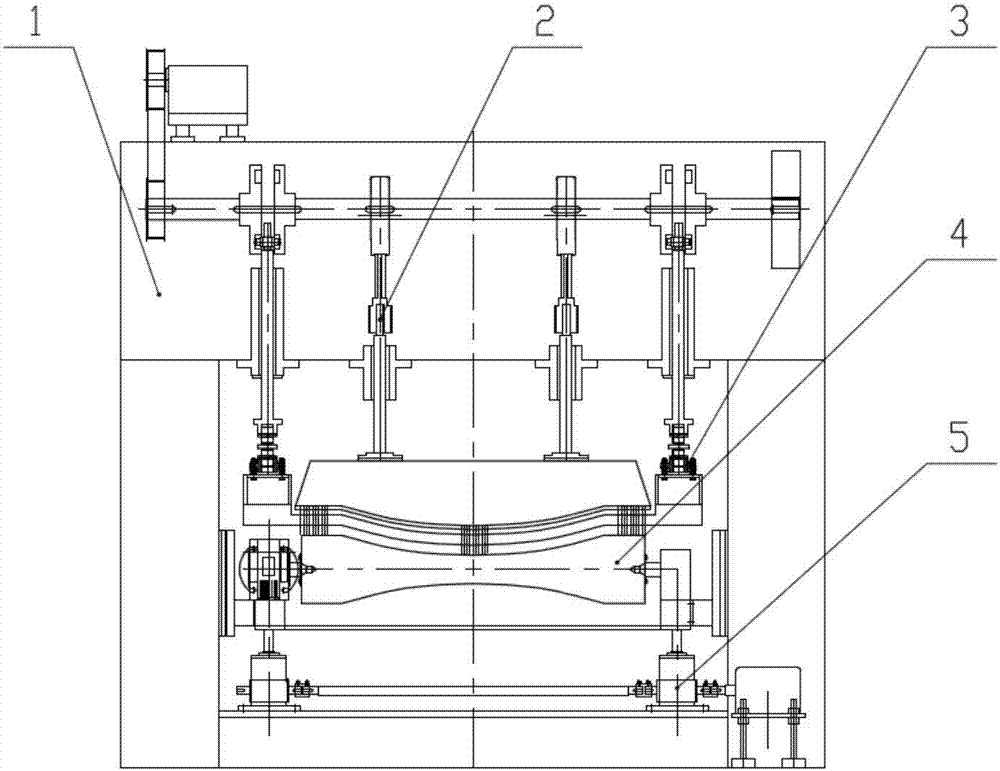

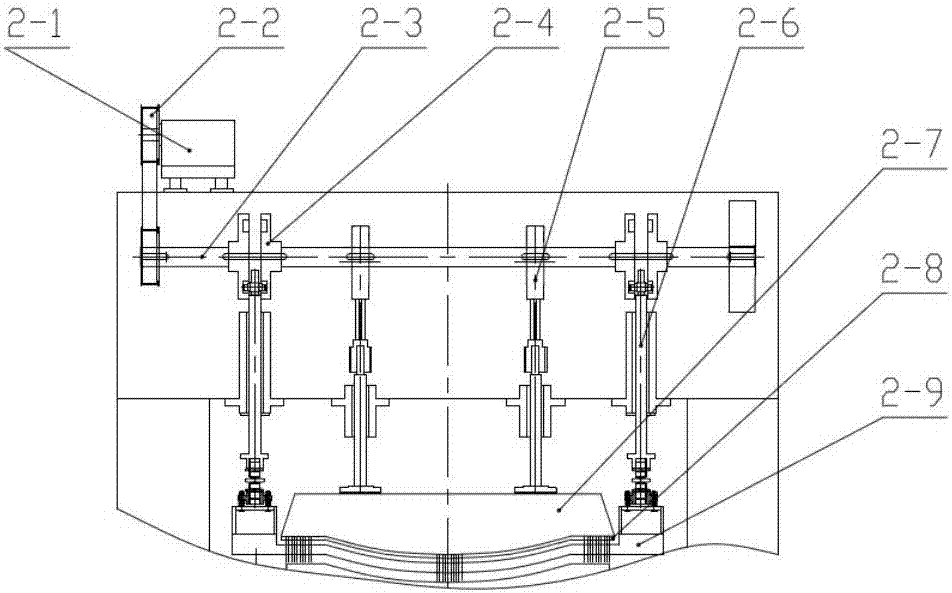

[0037] As shown in the figure, the variable-diameter rotating body acupuncture forming equipment includes a frame, an acupuncture mechanism, a pressure feedback and adjustment device, a mold rotation mechanism, and a mold lifting mechanism;

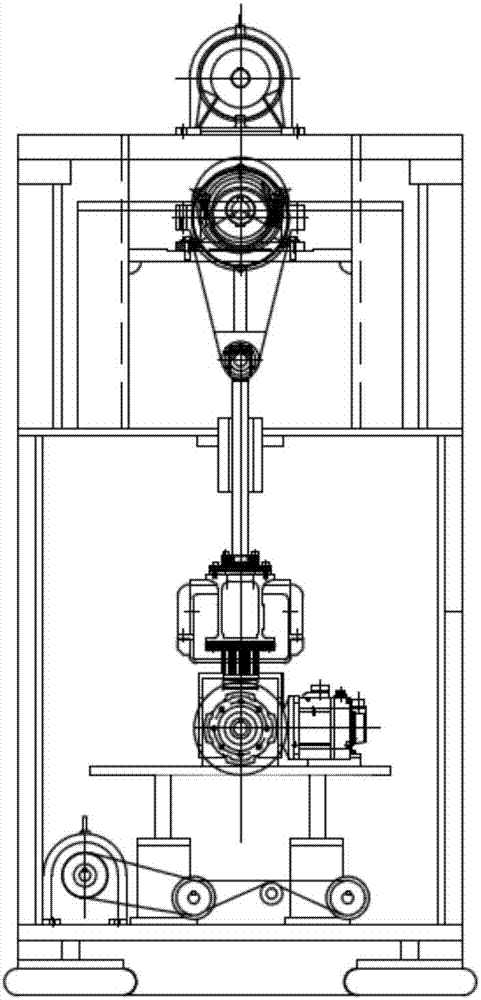

[0038]The acupuncture mechanism includes a servo motor 1, a pulley set, a main shaft, a pair of outer two-way cams, a pair of inner two-way cams, two inner connecting rods, two outer connecting rods, a needle beam, a profiling needle plate and a profiling stripping board ; The servo motor 1 is fixed on the top of the frame, and the servo motor 1 drives the main shaft to rotate through the pulley set; a pair of outer two-way cams and a pair of inner two-way cams are installed on the main shaft and reciprocate up and down on the main shaft, wherein a pair of inner The two-way cam is located between a pair of outer two-way cams; one pair of inner two-way cams are respectively connected to the needle beam through two inner connecting rods, and...

Embodiment 2

[0044] It is basically the same as Embodiment 1, except that the bevel gear set includes large bevel gears, small bevel gears, small bevel gear connecting shafts and fixed seats; the large bevel gears and the small bevel teeth are meshed at 90°; The bevel tooth connecting shaft is connected with the fixed seat, the small bevel tooth connecting shaft is connected with the servo motor 2, and the fixed seat is fixed on the lifting platform.

Embodiment 3

[0046] It is basically the same as that of Embodiment 1, except that the variable-diameter rotating body acupuncture forming equipment also includes a control system, which includes a man-machine interface, a PLC programmable logic controller, a controller connected to the servo motor, and a The pressure sensor used to detect the pressure realizes the coordinated movement of the acupuncture mechanism, the mold rotation mechanism and the mold lifting mechanism, as well as the closed-loop control of the pressure feedback of the stripping plate.

[0047] Before the needle punching process of the above-mentioned equipment, the unit layer composed of the mesh tire and the base cloth needs to be evenly wrapped on the mold. After the needle punching is completed, the layered layer is wrapped, and the needle punching is continued until the product thickness is finally reached.

[0048] In the production process, the servo motor 1 in the acupuncture mechanism drives the main shaft to ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com