Method for first-beam-later-pier construction of pier top section of cable-stayed bridge auxiliary pier

A construction method, the technology of beams first and piers later, is applied in the direction of cable-stayed bridges, bridges, bridge materials, etc., and can solve the problems of destroying the concrete structure of the support, reducing construction efficiency, and high construction cost, so as to achieve accurate elevation position and improve construction efficiency. Reasonable effect of efficiency and stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

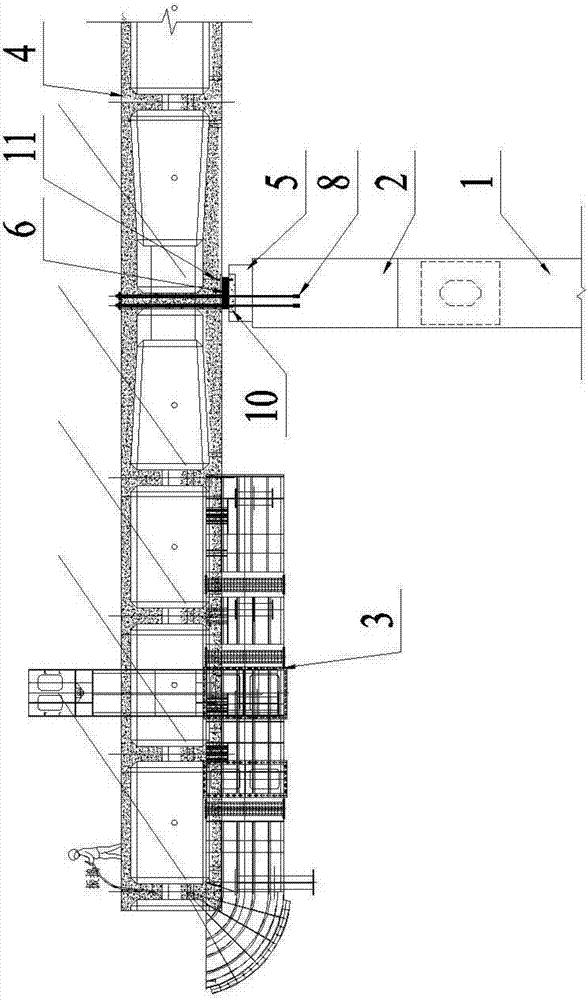

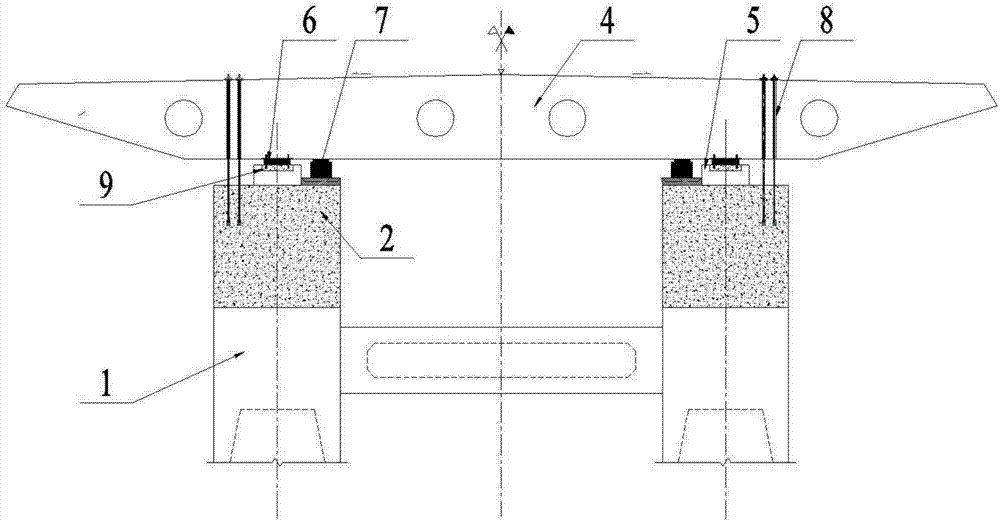

[0031] Such as Figure 1~2 , the construction of the auxiliary pier in this embodiment is carried out twice. The first construction of the auxiliary pier body segment 1 reserves the walking space for the front fulcrum hanging basket 3, and the front fulcrum hanging basket 3 pours the beam body 4, and the current fulcrum hangs After the basket 3 has poured the beam body 4 above the auxiliary pier, the front fulcrum hanging basket 3 advances along the beam body pouring direction and passes through the space above the auxiliary pier. Then pouring is performed for the second time, and the pier top segment 2 above the auxiliary pier pier body segment 1 is poured for the second time, and then the support 6 is installed on the pier top segment 2 .

[0032] In order to avoid the swaying of the floating beam body 4 after the support 6 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com