A low-noise and high-efficiency wind blade

A wind blade and high-efficiency technology, which is applied in the direction of wind turbines that are consistent with the wind direction, wind turbines, and wind turbines that are at right angles to the wind direction, etc., can solve problems such as accelerated wear of bearing components, impact on power generation efficiency, shutdown events, etc., to achieve optimization Noise reduction effect, optimization of noise reduction effect, effect of avoiding shutdown events

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

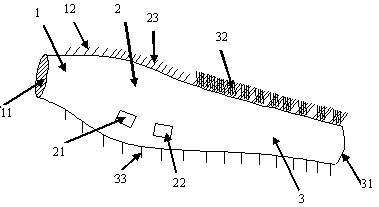

[0031] Such as figure 1 as shown,

[0032] A low-noise and high-efficiency wind blade includes a blade root, a wingspan, a blade tip, a noise reduction component, and a wind guide component.

[0033] The blade root is located at the root of the entire wind blade, and is connected to the impeller hub of the wind generator at the blade root connection at the root, so as to fix the entire wind blade on the impeller hub.

[0034] The wingspan part is located between the blade root and the blade tip, its width gradually increases from the blade root, then extends to the blade tip and then gradually decreases, and the interior is partially hollow to form an air guide channel communicating with the blade tip .

[0035] The blade tip is provided with an air outlet of the air guide channel at one end of the tip.

[0036] The noise reduction parts are made of thin rubber strips, including the noise reduction parts of the blade root, the noise reduction parts of the wingspan, the nois...

Embodiment 2

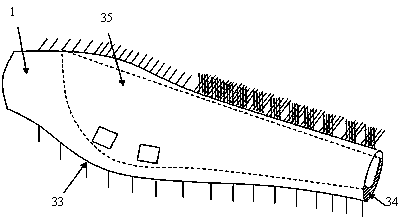

[0054] Such as figure 1 and figure 2 Shown: a low-noise and high-efficiency wind blade, including a blade root, a wingspan, a blade tip, a noise-reducing component, and a wind-guiding component.

[0055] The blade root is located at the root of the entire wind blade, and is connected to the impeller hub of the wind generator at the blade root connection at the root, so as to fix the entire wind blade on the impeller hub.

[0056] The wingspan part is located between the blade root and the blade tip, its width gradually increases from the blade root, then extends to the blade tip and then gradually decreases, and the interior is partially hollow to form an air guide channel communicating with the blade tip .

[0057] The blade tip is provided with an air outlet of the air guide channel at one end of the tip.

[0058] The noise reduction parts are made of thin rubber strips, including the noise reduction parts of the blade root, the noise reduction parts of the wingspan, the...

Embodiment 3

[0074] A low-noise and high-efficiency wind blade includes a blade root, a wingspan, a blade tip, a noise reduction component, and a wind guide component.

[0075] The blade root is located at the root of the entire wind blade, and is connected to the impeller hub of the wind generator at the blade root connection at the root, so as to fix the entire wind blade on the impeller hub.

[0076] The wingspan part is located between the blade root and the blade tip, its width gradually increases from the blade root, then extends to the blade tip and then gradually decreases, and the interior is partially hollow to form an air guide channel communicating with the blade tip .

[0077] The blade tip is provided with an air outlet of the air guide channel at one end of the tip.

[0078] The noise reduction parts are made of thin rubber strips, including the noise reduction parts of the blade root, the noise reduction parts of the wingspan, the noise reduction parts of the blade tip and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com