Pressure barrel of RO water purifier

A pressure tank and water purifier technology, applied in the direction of pressure vessels, functional valve types, gas/liquid distribution and storage, etc., can solve the problems of poor safety of pressure tanks, and achieve the effect of reducing material usage and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

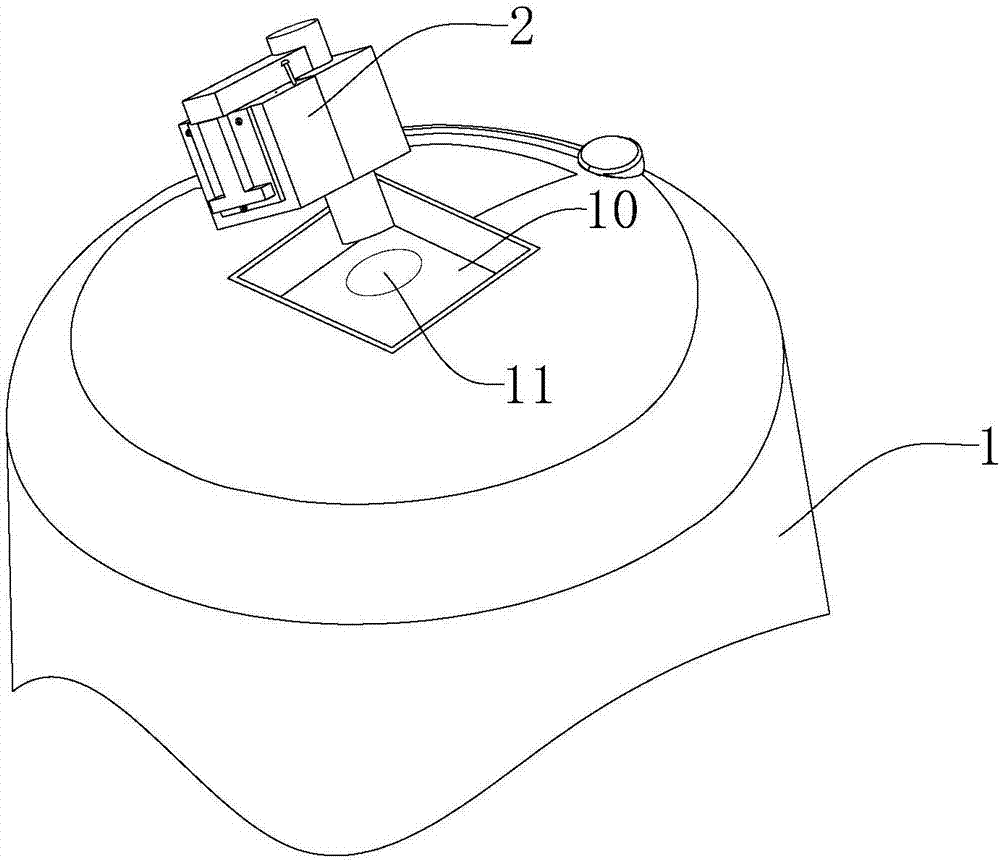

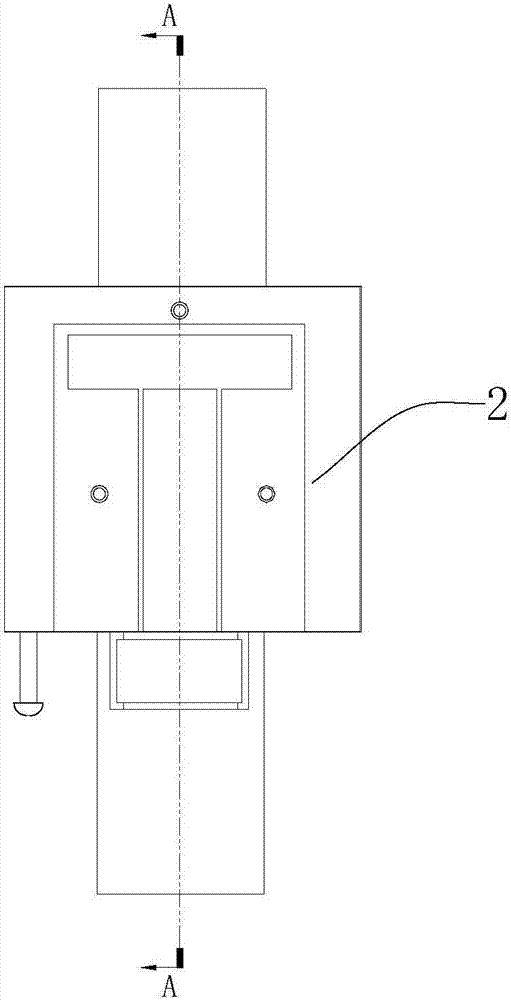

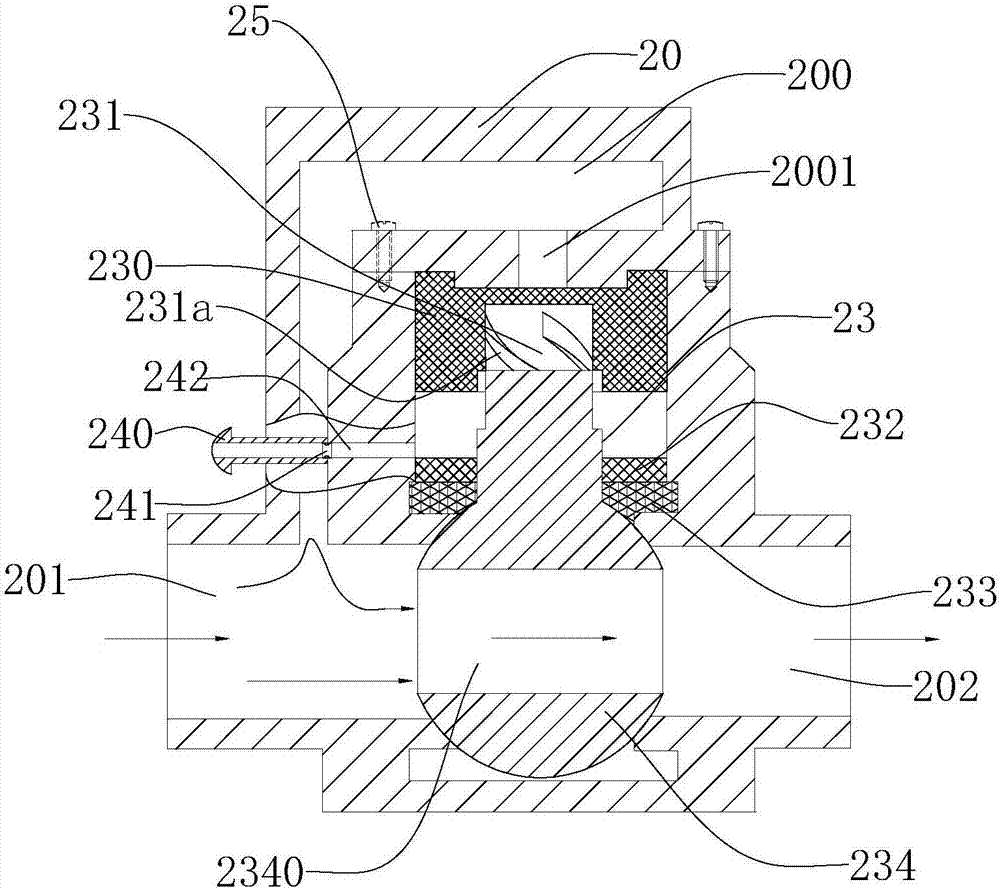

[0024] Such as Figures 1 to 5 The shown pressure barrel used in the water purification system includes a pressure barrel body 1, a pressure limiting valve installation groove 10 is provided on the top of the pressure barrel body 1, and a pressure limiting valve installation groove 10 is opened for water to enter the barrel. Inside the inlet and outlet 11, the pressure limiting valve 2 is packed into the pressure limiting valve installation groove 10 and the pipe at the output end stretches into the inlet and outlet 11. Wherein the pressure limiting valve 2 is a normally open valve that can automatically close and cut off the water injection when exceeding a certain injection water pressure threshold, and automatically open the water outlet when it is lower than the threshold. Its specific structure is as follows:

[0025] The pressure limiting valve 2 includes a valve seat 20 , a ball valve spool 234 and a piston assembly 23 for driving the ball valve spool to rotate. The v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com