Mechanical sealing structure with honeycomb-shaped groove in cylindrical surface

A mechanical seal, honeycomb-shaped technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problem of uneven heating of the end surface, save production materials, prolong the service life, enhance the sealing lubrication effect and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

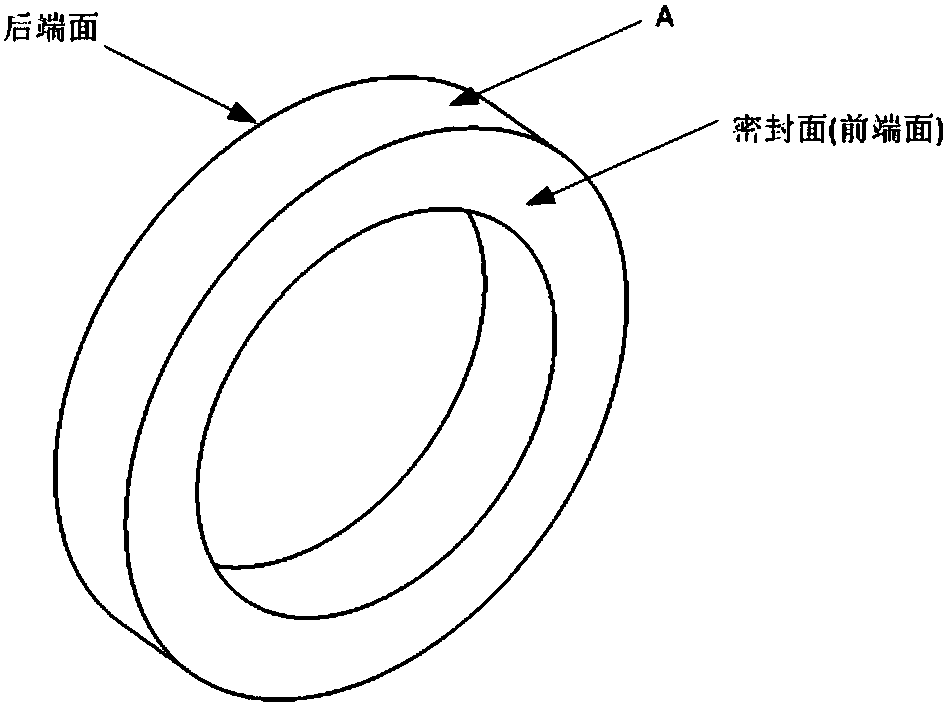

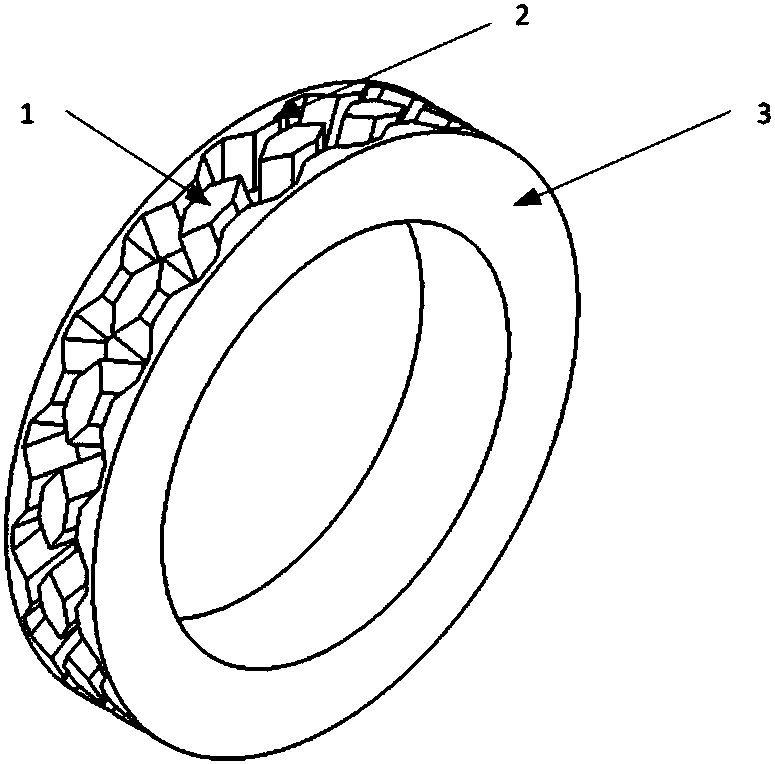

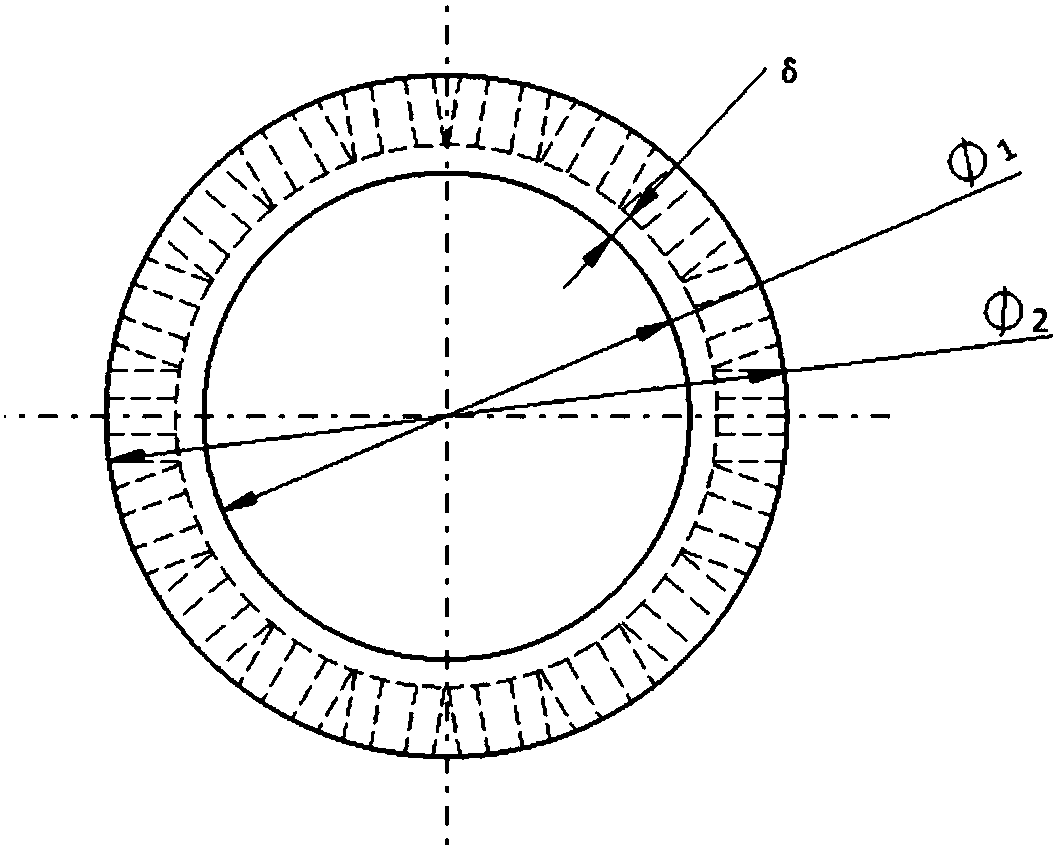

[0041] The structure of the mechanical seal structure embodiment of the present invention is as follows Figure 1 to Figure 8 shown. It includes a hexagonal column 1 in the ring groove, a reinforcing rib 2 on the sealing end surface, and a sealing surface 3 . The inner diameter of the whole mechanical seal structure is outer diameter is The axial thickness of the mechanical seal structure is L, and the thickness of the bottom of the circumferential groove of the mechanical seal structure is δ. The hexagonal column 1 in the ring groove is located in the middle of the groove, the width of the two parallel and opposite sides 4 and 5 is c, the length of the two parallel and opposite sides 4 and 5 is d, and the distance between the two vertices is e. 18 uniformly distributed along the circumference of the mechanical seal structure and with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com