Dust-proof electric fireplace

An electric fireplace and dust-proof technology, applied in the direction of electric light source, circuit layout, electric heating system, etc., can solve the problems of increased fan noise and low air intake efficiency of the air inlet, and achieve the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

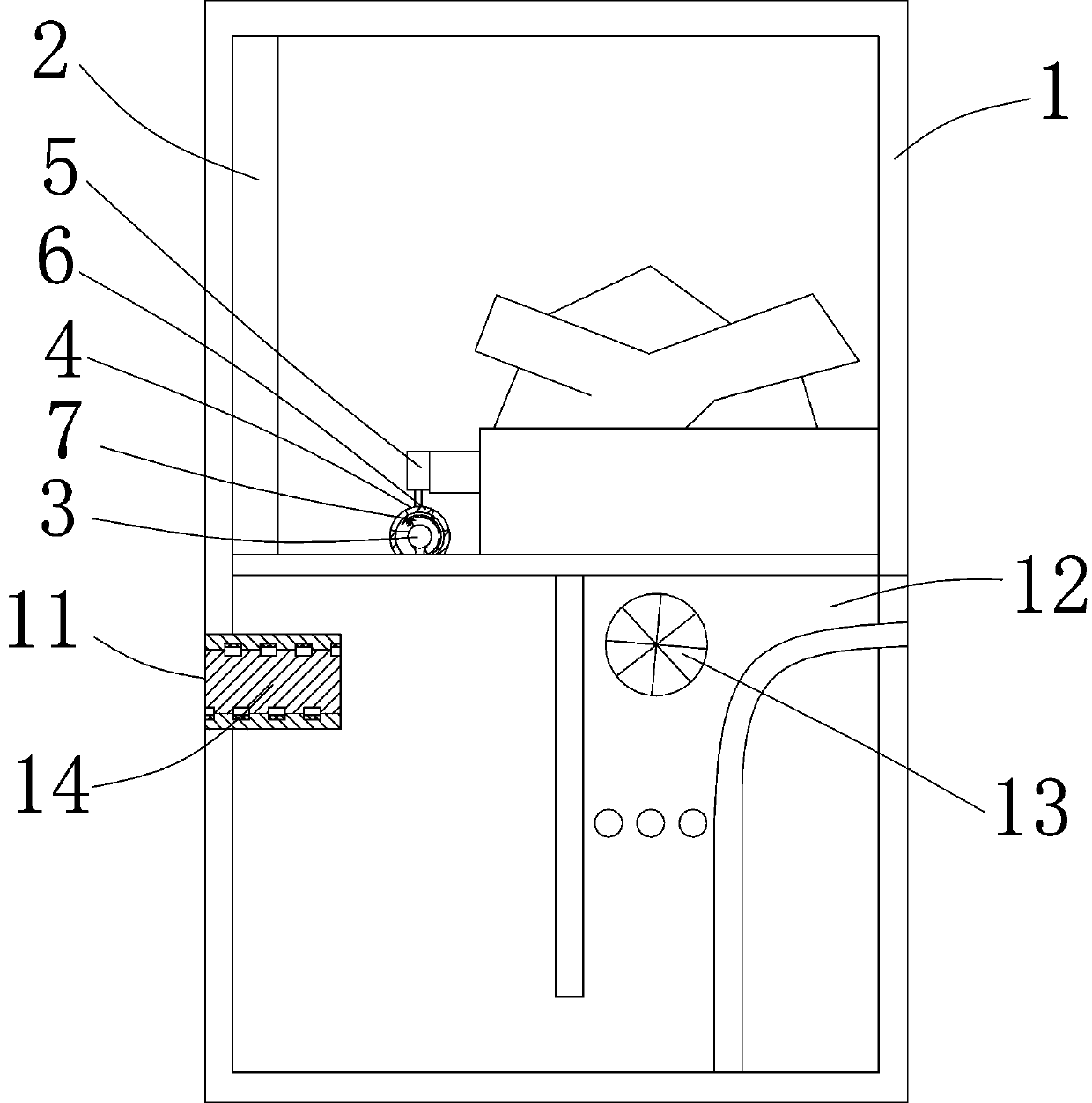

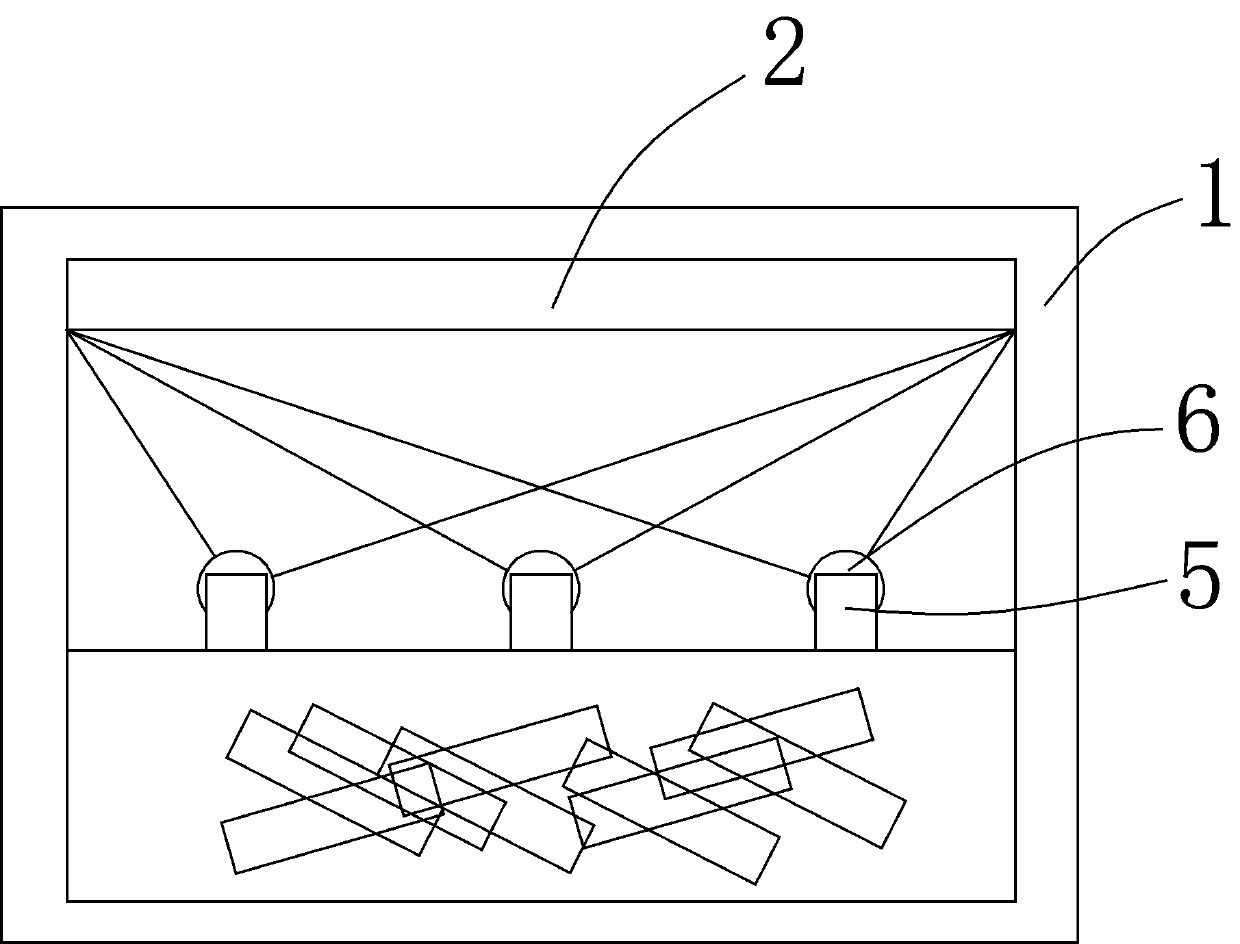

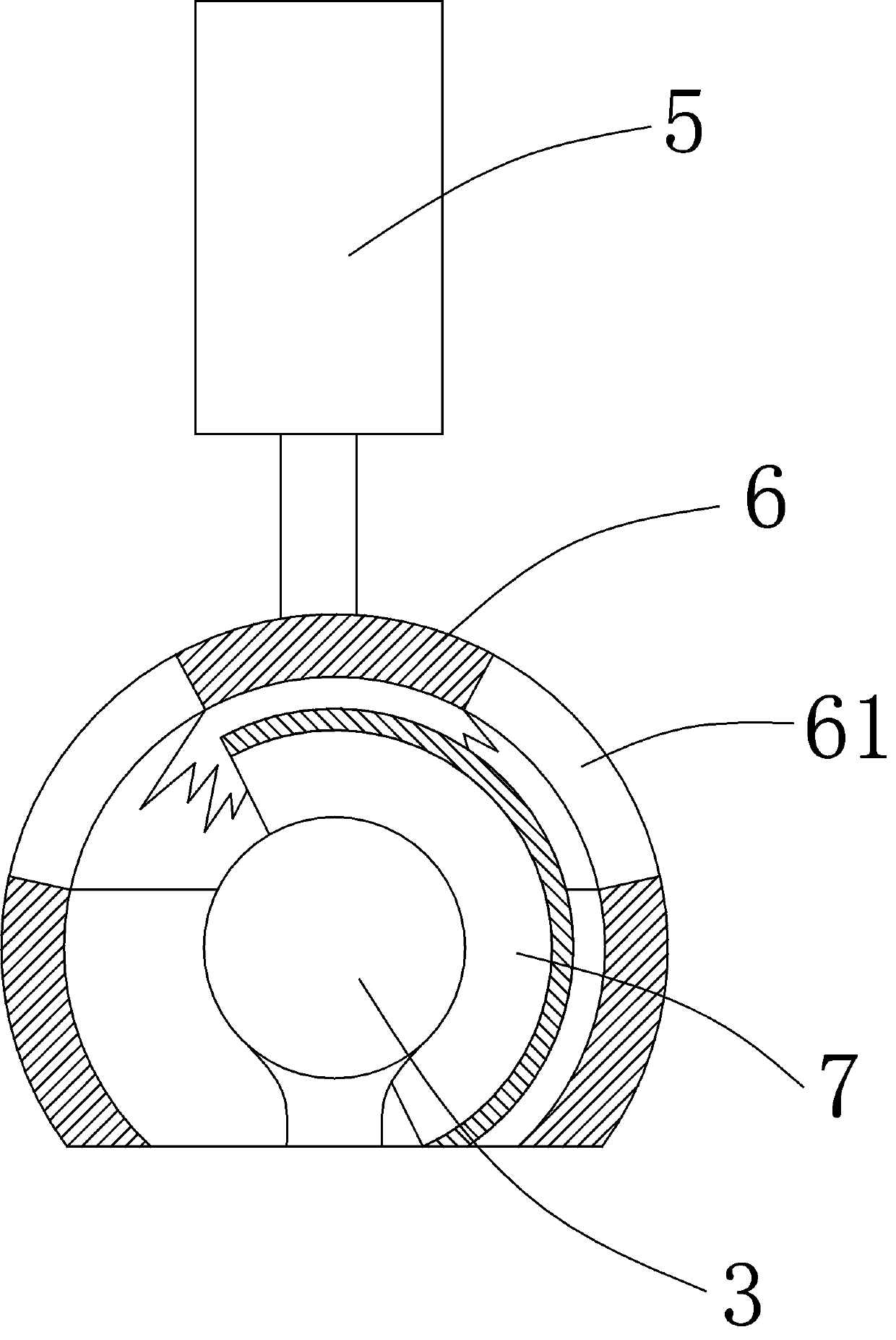

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 4 , a dust-proof electric fireplace, including a box body 1, an air inlet 11, an air outlet 12, and a fan 13 are arranged in the box, an air inlet and dust removal device 14 is arranged inside the air inlet 11, and the air inlet and dust removal device 14 includes A base block 15 and a core block 16, the base block 15 has a circular through hole 17, the inner wall of the through hole 17 is provided with a first spiral groove 18, and the outside of the core block 16 is provided with a second spiral groove Groove 19, the core block 16 protrudes into the through hole 17 and the first helical groove 18 and the second helical groove 19 are combined to form a helical channel 110, the first helical groove A plurality of adhesive tapes 111 are pasted and stacked in the groove 18 . With this structure, dust and flocculent impu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com