A belt automatic loading machine

An automatic loader and ammunition chain technology, applied in the direction of ammunition supply, offensive equipment, weapon accessories, etc., can solve the problems of manual and manual loading of machine gun ammunition chains, and the workload of war service support is large, so as to be convenient for marching and carrying. , compact structure, improve the effect of loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

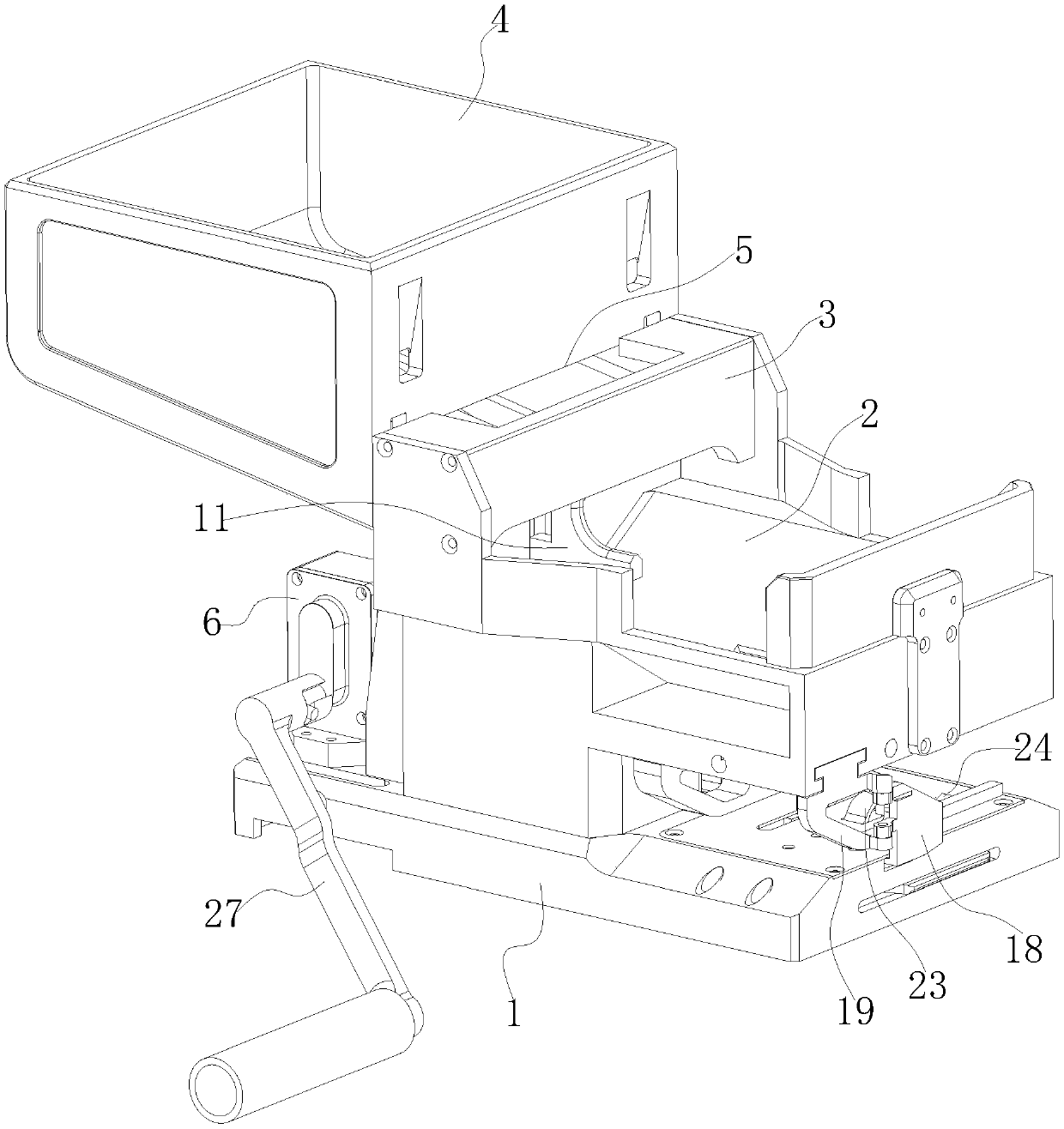

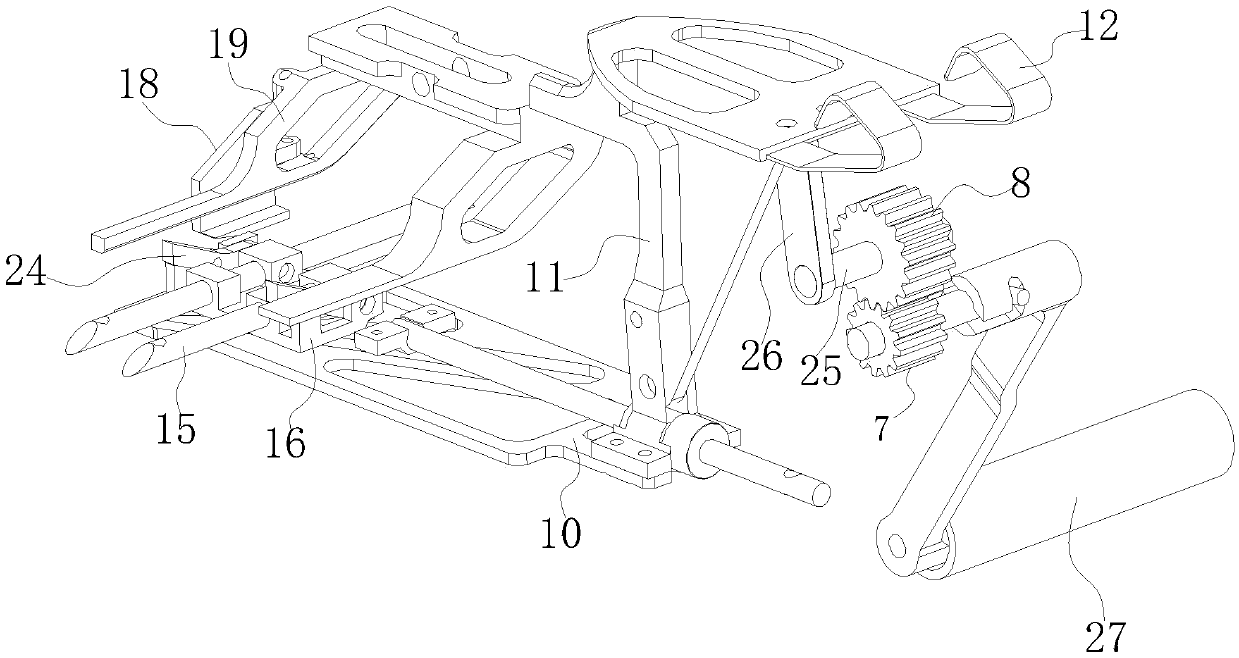

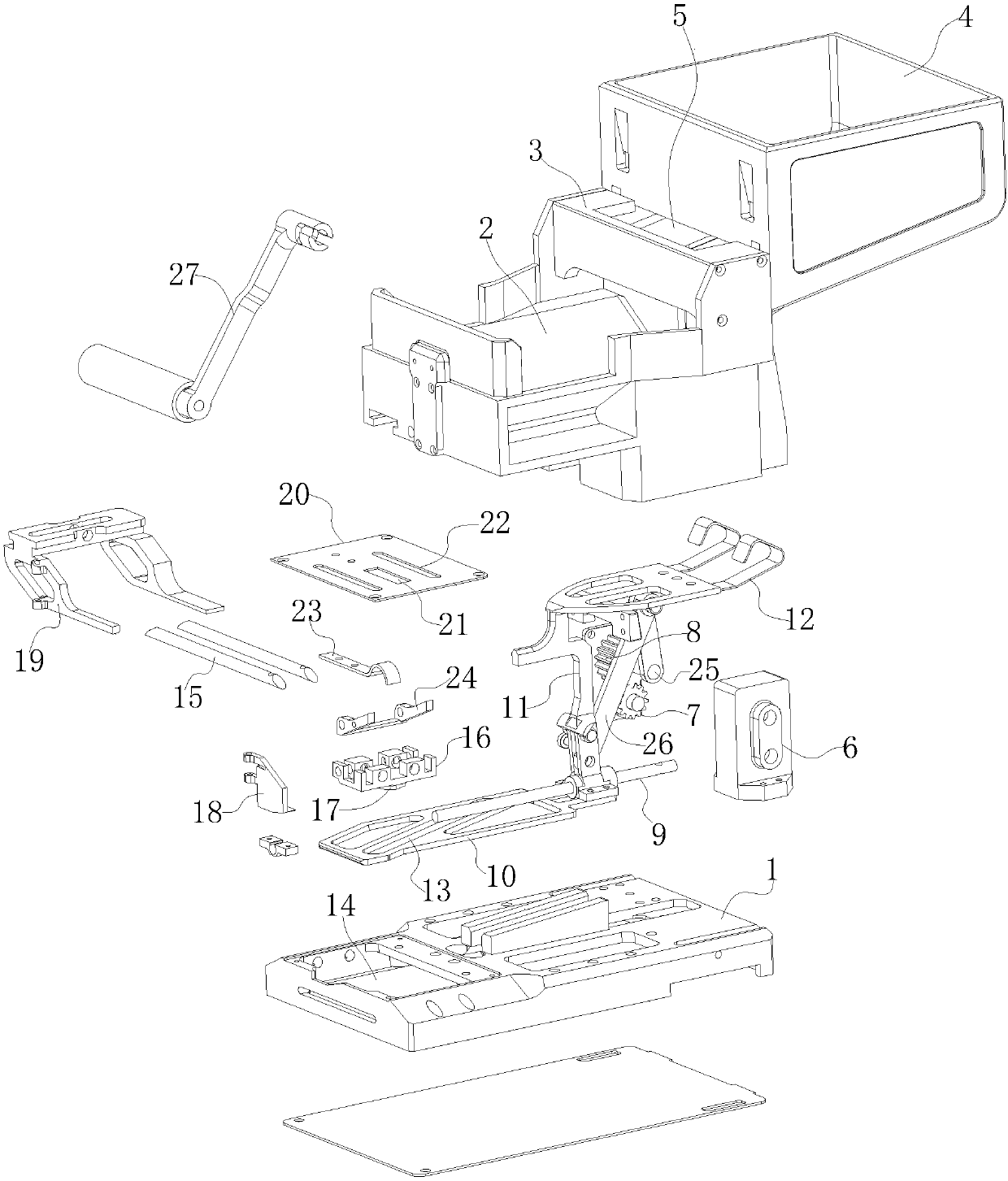

[0019] Embodiment one: combined with attached figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, an automatic loading machine for bullet chains includes a base 1 on which a bullet tank body 2 composed of a left bullet tank body and a right bullet tank body is installed, and a smooth bullet stopper is installed on the bullet tank body 2 Plate 3 and bullet bucket 4, and bullet bucket 4 is provided with notch towards the baffle plate 35 of the bullet; Gear box 6 is also installed on the base 1, and driving gear 7 and driven gear 8 are installed in the gear box 6, and driving gear 7 The drive gear shaft is connected to the external input device, the input device in this embodiment is the crank 27, the driven gear 8 is connected to the external crankshaft structure through the driven gear shaft, and the crankshaft structure is driven to connect the pressure spring assembly structure; The ball-pressing assembly structure can move back and forth on the ball-press...

Embodiment 2

[0022] Embodiment 2, the input device of this embodiment is a battery pack and a motor instead of a crank, and the battery pack is an ultra-low temperature battery pack to adapt to harsh environments. This embodiment can save the manpower operation for loading, and the automatic loading can be completed by the motor, and the loading efficiency is higher.

[0023] Structural principle of the present invention is:

[0024] Normal working process: use the motor or manual crank 27 as the external power input device to drive the driving gear 7 to rotate, the driving gear 7 meshes with the driven gear 8 to rotate, and the driven gear 8 drives the crank arm 25 of the crankshaft structure to rotate, and the crank arm 25 drives connecting rod 26 to rotate, and connecting rod 26 rotates and drives the ball pressing assembly structure to move back and forth to realize the process of pressing the ball. The bullet is put into the bullet bucket 4 of the bomb pressing assembly, and the bull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com