Microvibration blasting process of metro double-line large-span tunnel

A large-span, tunnel technology, applied in blasting, discharge machinery, earthwork drilling and mining, etc., can solve the problem that the vibration velocity value of explosive blasting cannot meet the requirements of construction and environmental protection, and achieve remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

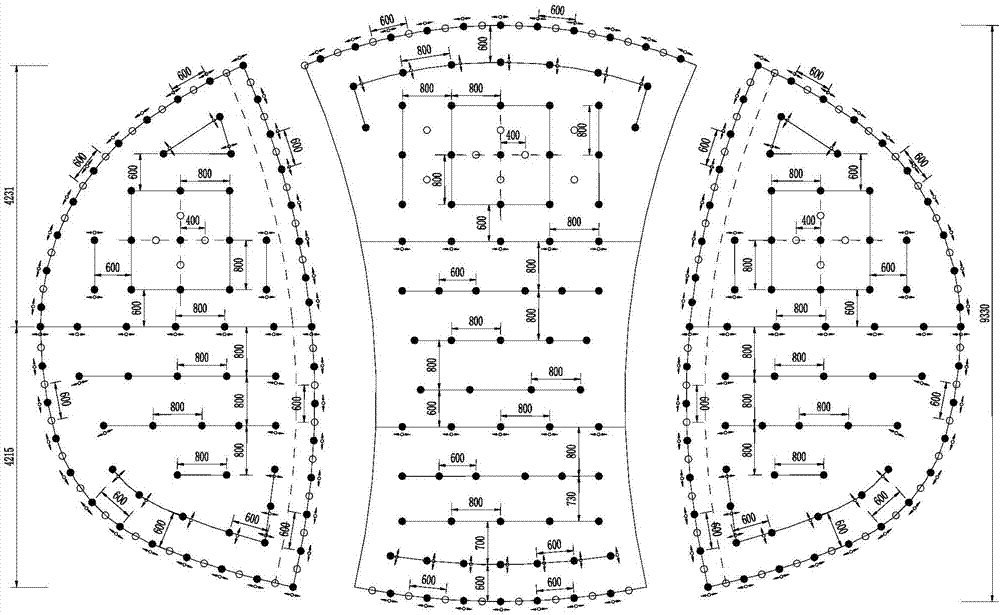

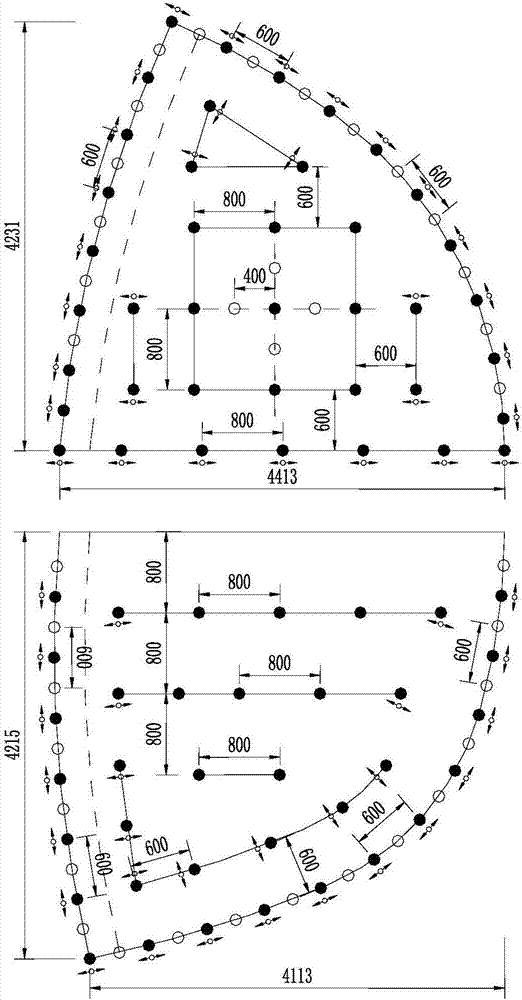

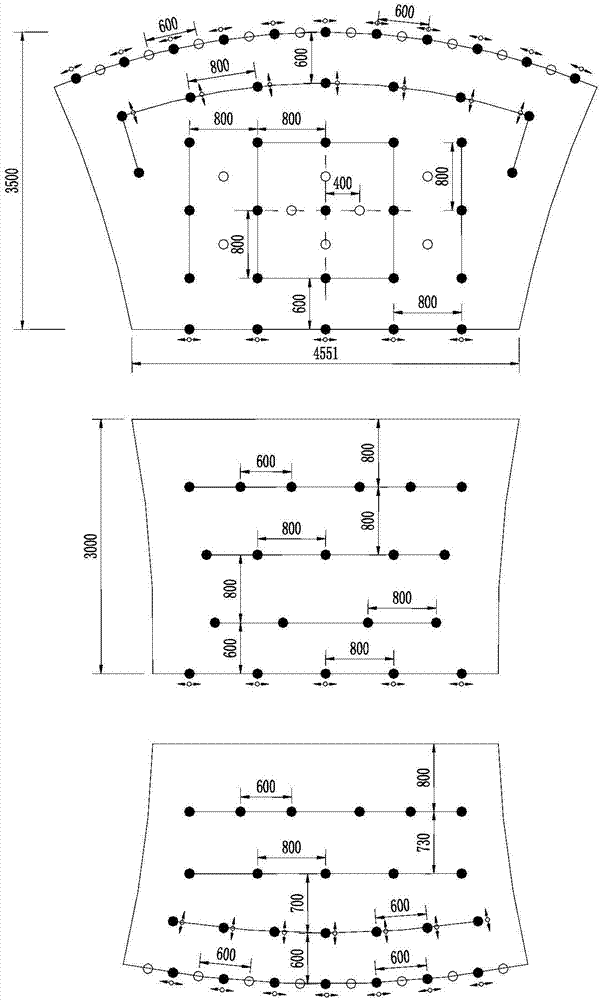

[0064] The invention provides a micro-vibration blasting process for a subway double-track long-span tunnel, which is characterized in that: the blasting method uses a carbon dioxide phase-change cracker as blasting equipment, and achieves the purpose of tunnel excavation through the rapid expansion of liquid carbon dioxide in the tube; Cracker length control The drilling depth is not less than 1.5m, and the hole diameter is not more than 63mm; set up peripheral eye pre-splitting guide holes, the hole distance is 10-50cm, and the hole depth is 20-30cm smaller than the cracking hole;

[0065] According to the design footage depth, choose a cracker with a length of 1000mm or 1500mm. The cracker used in this patent design is the MZL150-53 / 1500 cracker. The length of the cracker is 1.5m, and the expansion pressure is 150Mpa; the drilling tool uses a YT-28 hand-held pneumatic drill, and the diameter of the drill bit is After the hole is formed, the diameter is about 63mm; this de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com